Flaker Machines in Food and Chemical Processing A Smart Investment

Flaker machines are quickly revolutionizing modern food and chemical processing industries, offering an unmatched level of efficiency, precision, and reliability.

Jun 09,2025

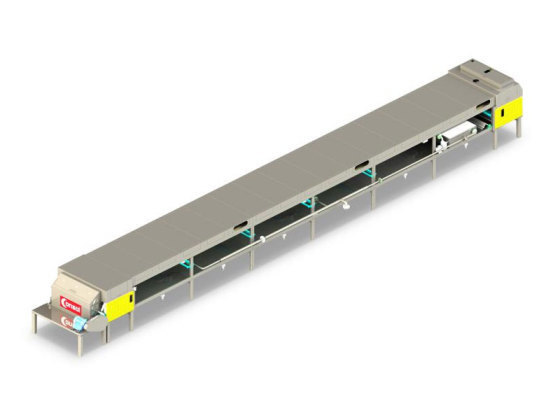

Flaker machines are quickly revolutionizing modern food and chemical processing industries, offering an unmatched level of efficiency, precision, and reliability. More than just machines, they represent innovative technology tailored to the evolving needs of global industrial operations. Leading flaker machine suppliers, such as Consol, focus on integrating advanced cooling systems and customizable manufacturing solutions that set a high benchmark within the industry. Their innovative capabilities not only streamline production but also help industries maintain superior quality standards while maximizing cost efficiency. Whether you're producing chemicals, food products, or composite materials, understanding how flaker machines like the single belt flakers work, and the value they offer can reshape your operational output significantly.

Table of contents:

Applications of Single Belt Flakers in Modern Production Lines

Meeting Quality Standards with Precision Cooling and Flaking Technology

Cost vs Performance What Large Buyers Should Consider

Applications of Single Belt Flakers in Modern Production Lines

Single belt flakers are versatile machines used extensively in industries such as food processing, chemicals, pharmaceuticals, and composite manufacturing. Whether the goal is to flake chocolate for confectionery production or to prepare resin granules for industrial use, their uniformity and precision drive operational excellence. Due to the design, single belt flakers allow consistent cooling and reliable flaking of materials with varying melting points. This precision is crucial in applications requiring strict compliance with regulations and quality benchmarks, such as pharmaceutical-grade products or premium confectionery items. Additionally, these systems integrate seamlessly with broader industrial cooling solutions to further enhance efficiency while reducing energy consumption. Industries often look for suppliers that understand their need to handle multiple materials, whether they are dealing with food-safe processing or chemical production at a large scale.

Meeting Quality Standards with Precision Cooling and Flaking Technology

The core of the single belt flaker machine lies in its precision-engineered cooling and flaking systems. Machines like those offered by Consol provide uniform heat transfer, ensuring that materials are cooled at a consistent rate across all batches. This uniformity is essential for industries like food production, where any variation can severely compromise the taste or quality. For the chemical industry, too, maintaining consistent batch quality is critical to meeting regulatory standards or ensuring end-product functionality. Advanced temperature settings, automated shutoff systems, and micro-based controls further add to the precision these systems offer. Investments in high-end flaker machines thus directly translate to the production of superior-quality materials that stand out in competitive markets. Additionally, these flakers are often equipped to process large quantities with no losses, making them an indispensable asset for meeting industrial-scale demands while retaining consistent quality output.

Cost vs Performance What Large Buyers Should Consider

For large enterprises weighing their investment in flaker machines, cost and performance have always been the primary considerations. High-quality flakers may seem like a large upfront investment, but their value lies in long-term cost savings and increased productivity. Suppliers such as Consol emphasize not only operational efficiency but also sustainability, ensuring less energy usage without sacrificing output quality. Furthermore, flaker machines with low maintenance requirements and long operational lifespans lower the total cost of ownership. Advanced designs with flexible configurations allow manufacturers to address varying production needs without having to invest in multiple machines. Prospective buyers can look at additional features like customizable cooling cycles, microprocessor controls, and seamless integration capabilities with industrial cooling solutions as added advantages. Opting for a machine that prioritizes durability and reliability ensures fewer interruptions, creating a smooth workflow that maximizes ROI.

Investing in modern single belt flakers from reputed flaker machine suppliers like Consol ensures businesses are prepared to meet increasing demands for quality and consistency in industrial production. Those exploring technology upgrades can discover how this precision cooling and flaking can advance their manufacturing goals, reduce unit costs, and align their equipment with future-proof technology. If operational efficiency and superior quality guarantees are non-negotiable for your industry, exploring the offerings from suppliers like Consol Steel Belt makes smart business sense.

Related Posts

Steel belt pastillator granulation production line for jewelry wax middle temperature wax

Rotary belt condensation pastillator granulator&pelletizer is using low melting point characteristic of the material (50 ℃ to 300 ℃), through the feeding head, the liquid material will drop into the upstream moving steel belt,with the continuous spray cooling device set at the bottom of the steel belt (spray type water cooling), materials will be cooled quickly and become solidification in the process of conveying

Contact Us

E-mail

info2@consolbelts.com

Phone/WhatsApp/Wechat

+86 18820135908