Choosing the Right Flaker Machine Supplier for Efficient Production Lines

Selecting the right flaker machine supplier is a critical decision for industries aiming to boost their production efficiency.

Jun 17,2025

Selecting the right flaker machine supplier is a critical decision for industries aiming to boost their production efficiency. With the growing demand for products that require precision flaking, such as chemicals, waxes, and resins, choosing a supplier who aligns with your operational needs is more important than ever. The flaker machine is a central component in industrial cooling solutions, playing a pivotal role in maintaining product consistency and optimizing output. This guide explores how to identify a reliable supplier, the benefits of advanced flaker machines, and the value of establishing robust supplier partnerships for long-term success.

Table of contents:

Key Features to Look for in a Reliable Flaker Machine Supplier

How Premium Flaker Machines Improve Product Consistency and Output

Supplier Partnerships That Drive Long-Term Industrial Success

Key Features to Look for in a Reliable Flaker Machine Supplier

A trustworthy flaker machine supplier should provide more than just high-quality equipment. They need to offer expertise, reliability, and tailored solutions to meet your production challenges. Look for suppliers who prioritize innovation in their manufacturing processes and integrate features like stainless steel belts, corrosion-resistant parts, and energy-efficient cooling systems in their machines. An ideal partner proves their commitment through comprehensive after-sales support, including maintenance services and seamless part replacements. Industrial cooling solutions often require precise calibration and material handling capabilities, ensuring consistent performance. Additionally, check for customer testimonials, case studies, or certifications that reveal the supplier’s ability to solve real-world challenges. A supplier's experience in your specific industry sector can also make a significant difference, as they bring insights that transform standard setups into efficient, high-performing systems tailored to your needs. Trustworthy suppliers actively collaborate with clients, continuously innovating to improve productivity and enhance system reliability.

How Premium Flaker Machines Improve Product Consistency and Output

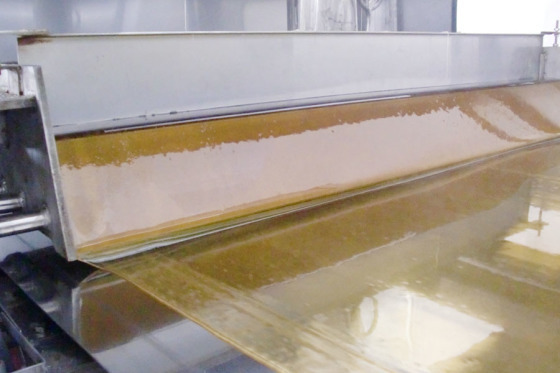

Investing in premium flaker machines can significantly enhance product quality and operational efficiency. High-performance machines ensure uniform flaking, reducing material waste and production defects. Precision mechanisms, such as those found in Consol’s single belt flaker systems, provide consistent cooling and even product distribution across the steel belts. These machines are designed for durability, reducing downtime and maintenance costs over time. Furthermore, incorporating robust flaker machines can streamline your product handling, offering scalability without compromising performance. The advanced configurations available today, featuring fine-tuned controls and automation, give manufacturers an edge in maintaining consistent quality even as production volumes increase. Whether for chemicals, waxes, or food-grade products, prioritizing equipment with advanced technical features aligns with global manufacturing standards and ensures your production can adapt to evolving market demands.

Supplier Partnerships That Drive Long-Term Industrial Success

The supplier-manufacturer relationship plays a crucial role in long-term industrial success. Beyond providing machinery, a reliable flaker machine supplier should act as a partner in innovation and operational growth. This includes offering timely upgrades, ongoing technical support, and customized solutions for unique production needs. Consol Machinery, for example, emphasizes customer-first engineering, helping industries develop scalable production setups tailored to their goals. Suppliers who invest in their clients’ success often help identify cost-saving opportunities, streamline processes, and future-proof production lines with adaptable technologies. Strong partnerships also pave the way for collaborative innovation, where suppliers contribute insights for developing next-generation industrial cooling solutions. By building a relationship grounded in mutual benefit, industries can not only meet but exceed their production goals while maintaining operational efficiency and product quality.

Opting for the right flaker machine supplier affects far more than just the initial purchase—it’s a decision with long-term implications for your business. The right supplier lays the groundwork for an efficient, scalable, and future-ready production line, giving you the tools to meet growing demands with ease. A supplier that combines cutting-edge technology, reliable machine performance, and deep expertise in industrial cooling solutions ensures you’re not just buying equipment but investing in your company’s long-term success. Additionally, a trusted partner can provide ongoing support, maintenance, and tailored solutions to meet your unique production needs. Choose your partner wisely to optimize your production outcomes today, adapt to challenges, and seize future growth opportunities.

Related Posts

Steel belt pastillator granulation production line for jewelry wax middle temperature wax

Rotary belt condensation pastillator granulator&pelletizer is using low melting point characteristic of the material (50 ℃ to 300 ℃), through the feeding head, the liquid material will drop into the upstream moving steel belt,with the continuous spray cooling device set at the bottom of the steel belt (spray type water cooling), materials will be cooled quickly and become solidification in the process of conveying

Contact Us

E-mail

info2@consolbelts.com

Phone/WhatsApp/Wechat

+86 18820135908