Enhancing Thermal Processing: Baking, Heating & Drying with Metal Conveyor Belt

Industrial thermal processing requires precision, reliability, and efficiency to meet demanding production standards.

Jul 04,2025

Industrial thermal processing requires precision, reliability, and efficiency to meet demanding production standards. When manufacturers need superior heat transfer capabilities for baking, heating, and drying operations, partnering with an experienced carbon steel belt supplier becomes essential for achieving optimal results. A trusted metal conveyor belt manufacturer can provide the specialized industrial belt conveyor solutions that deliver exceptional thermal performance through advanced industrial conveyor belt systems designed specifically for high-temperature applications.

Table of contents:

How Metal Conveyor Belt Performs in High-Heat Oven and Conveyor Dryer Environments

Carbon Steel Belt Benefits: Uniform Heat, Durability & Hygienic Performance

Retrofitting Existing Industrial Belt Conveyor Systems for Drying Liquid & Paste Foods

How Metal Conveyor Belt Performs in High-Heat Oven and Conveyor Dryer Environments

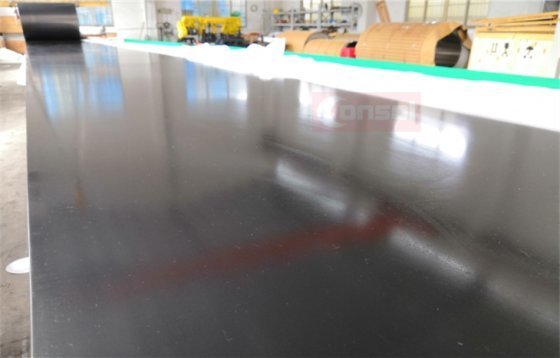

Metal conveyor belts perform exceptionally in high-temperature environments where traditional materials fall short. The CS1300 carbon steel belt maintains structural integrity under prolonged exposure to heat, thanks to its thermal stability. A protective oxide layer enhances corrosion resistance while preserving thermal conductivity for efficient heat transfer. The smooth surface minimizes product adhesion and allows easy cleaning, reducing downtime and maintenance. Expert manufacturers design these belts to handle thermal expansion and contraction without affecting alignment or tracking. Their sturdy construction ensures reliable performance in demanding industrial settings with temperature fluctuations and mechanical stress. Advanced tensioning systems keep proper belt tension during heating and cooling cycles, avoiding disruptions that could delay production. These systems are built to endure the harsh conditions of industrial ovens and dryers, ensuring consistent performance to maintain product quality and efficiency.

Carbon Steel Belt Benefits: Uniform Heat, Durability & Hygienic Performance

Carbon steel belts from trusted suppliers offer key advantages for thermal processing applications. Their superior thermal conductivity ensures even heat distribution across the belt surface, preventing hot spots that cause uneven processing or defects. With a tensile strength of 1250 MPa and excellent fatigue resistance, these belts are built for continuous operation in demanding industrial settings. The smooth, hard surface with a protective oxide coating meets strict food safety standards and allows for easy cleaning and sanitization. Reputable suppliers focus on dimensional stability, delivering belts that maintain consistent thickness and flatness throughout their lifespan. Reliable fatigue resistance ensures performance through millions of cycles, reducing replacement costs. These belts excel in applications like liquid, paste, and particle drying, where consistent heat transfer and product handling are critical. Combining thermal efficiency, mechanical strength, and hygienic properties, carbon steel belts are the go-to choice for manufacturers seeking dependable thermal processing solutions.

Retrofitting Existing Industrial Belt Conveyor Systems for Drying Liquid & Paste Foods

Upgrading existing industrial conveyor belt systems with carbon steel belts can significantly improve thermal processing efficiency and product quality. Professional installation services ensure proper integration with existing equipment, optimizing belt tensioning and alignment for maximum performance. The retrofit process involves careful evaluation of current system capabilities and requirements, with experienced suppliers providing customized solutions that maximize the benefits of carbon steel belt technology. Modern industrial belt conveyor systems incorporating carbon steel belts deliver measurable improvements in energy efficiency through enhanced heat transfer properties. The smooth surface characteristics of these belts reduce friction and power consumption while supporting consistent product flow through the drying process. Specialized edge treatments and perforation options can be tailored to specific application requirements, enhancing drying performance for liquid and paste food products. Professional suppliers offer comprehensive support throughout the retrofit process, including system analysis, belt selection, installation guidance, and ongoing maintenance support. The investment in quality carbon steel belt technology pays dividends through improved processing consistency, reduced energy costs, and extended equipment life that directly impacts operational profitability and production reliability.

Selecting the right carbon steel belt configuration requires careful consideration of application-specific requirements and operating conditions. Professional carbon steel belt suppliers provide expert guidance in belt selection, ensuring optimal thermal performance and operational reliability. The CS1300 specification offers excellent fatigue resistance and thermal properties, making it ideal for demanding thermal processing environments where consistent performance is essential. Working with experienced industrial conveyor belt systems manufacturers ensures proper system integration and long-term operational success through comprehensive support services and quality assurance programs.

Related Posts

Steel belt pastillator granulation production line for jewelry wax middle temperature wax

Rotary belt condensation pastillator granulator&pelletizer is using low melting point characteristic of the material (50 ℃ to 300 ℃), through the feeding head, the liquid material will drop into the upstream moving steel belt,with the continuous spray cooling device set at the bottom of the steel belt (spray type water cooling), materials will be cooled quickly and become solidification in the process of conveying

Contact Us

E-mail

info2@consolbelts.com

Phone/WhatsApp/Wechat

+86 18820135908