Aug 05,2024

Exploring the Customization Options for Double Belt Press Machines: A Comprehensive Guide

Exploring the Customization Options for Double Belt Press Machines Table of Contents 1. Introduction to Double Belt Press Machines 2. Importance of Customization in Manufacturing 3. Key Features of Double Belt Press Machines 3.1. Construction and Design Variations 3.2. Operational Capabilities 4. Customization Options for Double Belt Press Machines 4.1. Adjustable Pressure Settings 4.2. Belt Mater

Jul 30,2024

Understanding the Double Belt Press: A Key Technology in Metalworking

The Double Belt Press is a specialized machine commonly used in the metalworking sector, particularly for processes that involve the pressing and shaping of materials. This machine operates by using two parallel belts to apply uniform pressure on the material being processed, which helps in achieving precise dimensions and a superior surface finish. The design of the Double Belt Press allows for e

Jun 17,2024

Kenschau successfully installed an ultra-wide sheet production line in Europe

Kenschau successfully installed an ultra-wide sheet production line in Europe

Jun 17,2024

South Africa, Israel customers to visit our company, and discuss related business

South Africa, Israel customers to visit our company, and discuss related business

Jun 13,2024

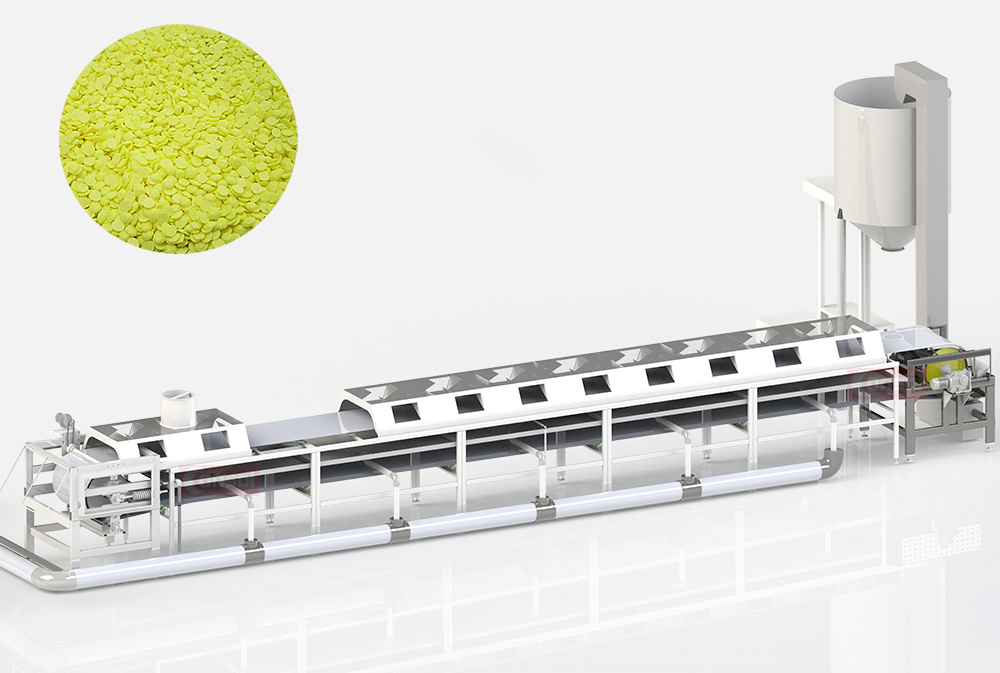

Boosting Efficiency in Plastic Granulation: The Sulphur Advantage

**Introduction** In the world of plastic manufacturing, efficiency is key to staying competitive and profitable. One way to boost efficiency in plastic granulation processes is by leveraging the Sulphur Advantage. In this article, we will explore the benefits of using sulphur in plastic granulation and how it can revolutionize your operations. **What is Plastic Granulation?** Plastic granulation i

Jun 07,2024

Optimizing Cooling Processes: Steel Belt Coolers for Steel Materials

**Introduction** When it comes to steel production, the cooling process is a critical step that can significantly impact the quality and performance of the final product. Steel belt coolers play a vital role in optimizing cooling processes for steel materials by ensuring uniform and controlled cooling rates. In this article, we will explore the key factors to consider when optimizing cooling proce

Jun 01,2024

Steel Belt Cooler: A Crucial Component in the Steel Materials Industry

Steel belt coolers are essential equipment in the steel materials industry, specifically in the production of steel strips and coils. These coolers are designed to efficiently and effectively cool down steel materials to the desired temperature, ensuring optimal quality and performance of the final product. One of the key functions of a steel belt cooler is to control the cooling rate of steel str

May 26,2024

The Ultimate Guide to Choosing the Right Conveyor System

**Introduction** In the world of industrial equipment and components, conveyors play a crucial role in streamlining processes and maximizing productivity. Whether you are looking to upgrade your current conveyor system or invest in a new one, choosing the right conveyor system is essential for the smooth operation of your facility. In this ultimate guide, we will walk you through everything you ne

May 20,2024

Solving Challenges in Material Handling with Conveyor Systems

**Introduction: The Importance of Conveyor Systems in Material Handling** Conveyor systems have revolutionized the way materials are transported and processed in industrial settings. From manufacturing plants to distribution centers, conveyor belts play a crucial role in ensuring smooth and efficient material flow. In this article, we will explore the various challenges faced in material handling

May 14,2024

Maximizing Strength and Performance: Aluminum Sulfate Solidification for Steel Strips and Coils

**Introduction** In the competitive world of construction and decoration materials, maximizing strength and performance is crucial for staying ahead of the competition. One innovative solution that has been gaining traction in the industry is the use of aluminum sulfate solidification for steel strips and coils. This process has been shown to significantly enhance the strength and durability of st

Related Posts

Steel belt pastillator granulation production line for jewelry wax middle temperature wax

Rotary belt condensation pastillator granulator&pelletizer is using low melting point characteristic of the material (50 ℃ to 300 ℃), through the feeding head, the liquid material will drop into the upstream moving steel belt,with the continuous spray cooling device set at the bottom of the steel belt (spray type water cooling), materials will be cooled quickly and become solidification in the process of conveying

Contact Us

E-mail

info2@consolbelts.com

Phone/WhatsApp/Wechat

+86 18820135908