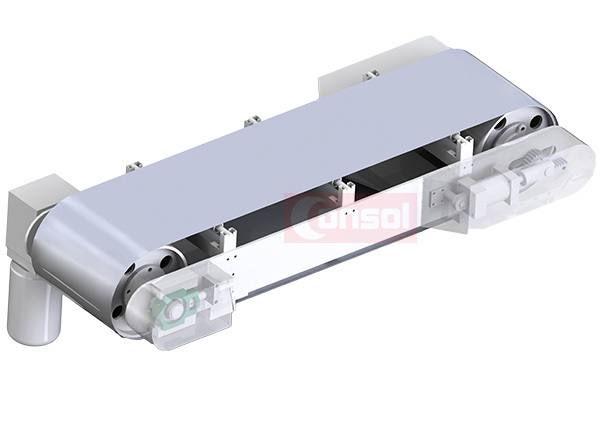

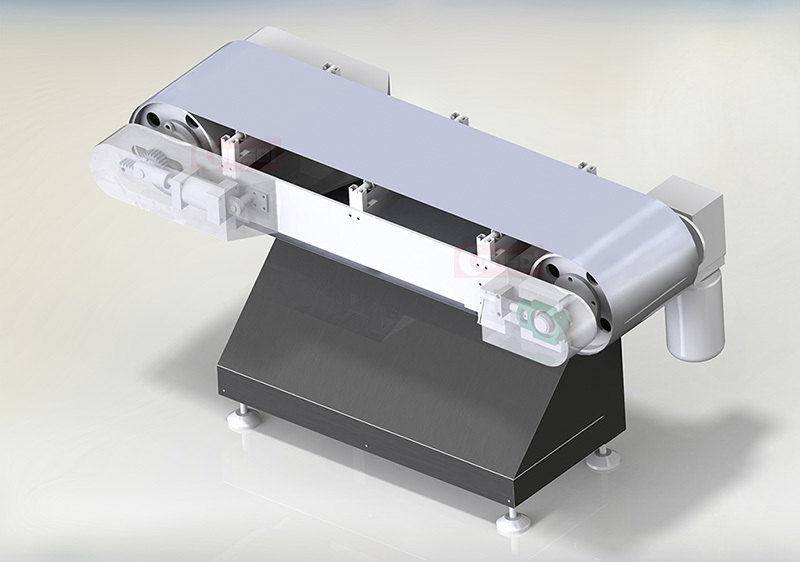

Steel belt conveyor design

2020-05-22

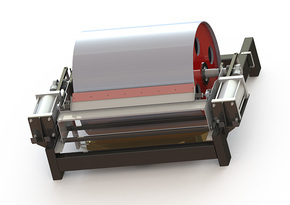

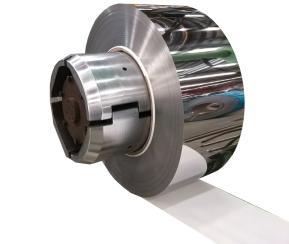

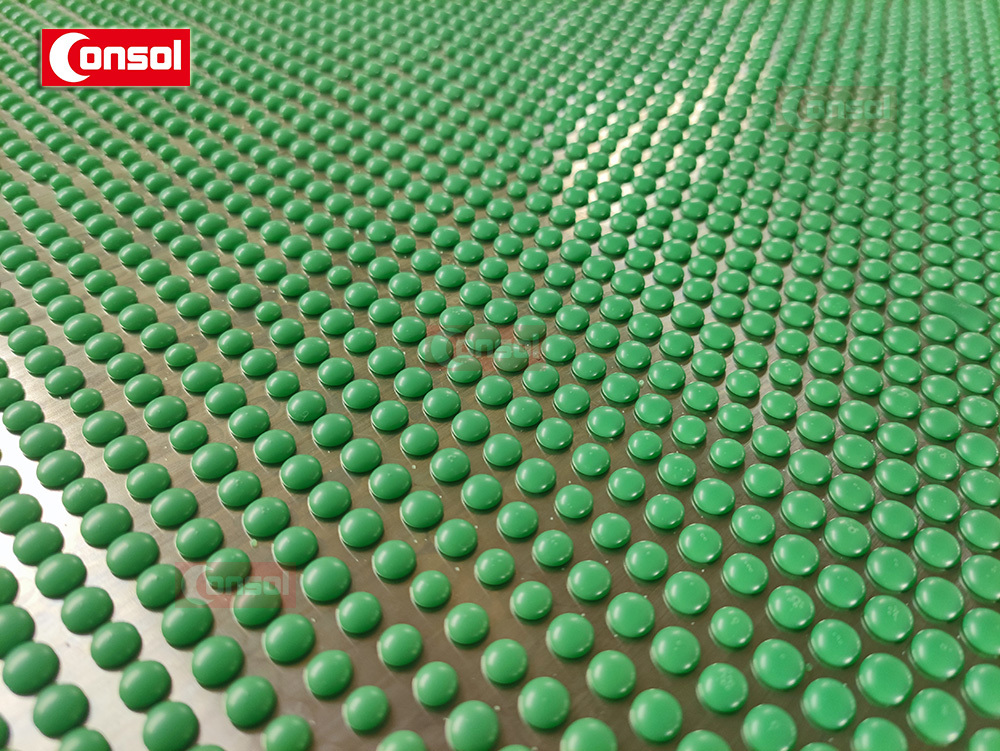

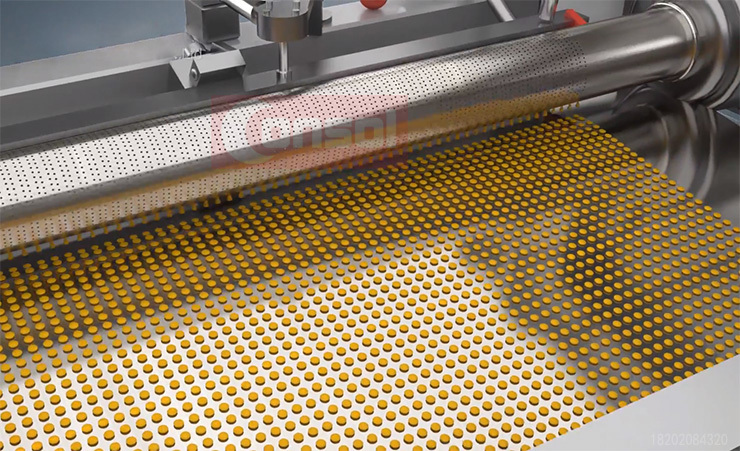

The steel belt conveyor is a type of belt conveyor that USES a highly malleable sheet steel as the conveyor belt.Often used in factory product transmission, food processing and other occasions.The materials used are SUS301, 304, 316, 430, 631, 15-7ph, SK, copper, etc.All steel strips have high ductility to suit the needs of different customers, ranging from 200 to 6000mm in width, from 0.4 to 3.0mm in thickness, and no specific range in length.In addition, the steel strip also has different degrees of treatment of the surface, can be manufactured according to customer requirements.

Excellent corrosion and wear resistance, exceptional durability even in hot and sour environments.

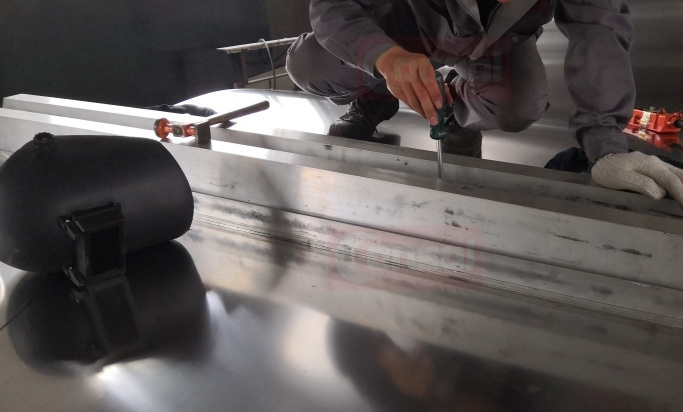

Position can be precisely determined without rewinding, vibration, and trip.The steel belt itself will not fall off, will not be damaged like the rubber conveyor belt, also will not be like the resin conveyor belt in the joint of the processing material accumulation, so will not be mixed with foreign bodies, the structure is simple, than the rubber or resin belt long life, so can save maintenance and management fees.

Steel belt surface hard and smooth, not easy to scratch, small scalability, not easy to deformation, can inhibit the proliferation of bacteria, heat, acid resistance, easy to clean, easy to keep the surface clean, products can be directly placed on the steel belt to carry.

Because the conveyor belt is metal, it has excellent anti-static function.

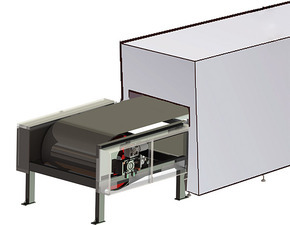

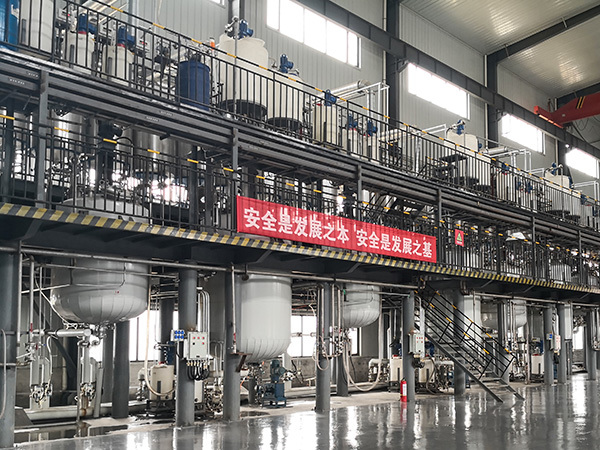

At present, in the paper sludge, tailings and other industries that need dehydration, there is a steel strip press, referred to as the steel strip machine. Through the pressure and shear force of the steel strip on the sludge, the purpose of dehydration can be achieved, so as to increase the sludge dryness and reduce the volume.

The steel belt is used as a high quality material for the transmission belt. Its strong but soft properties can be used for different industrial production processes. With its smooth surface, it can be exposed to a variety of different substances, so it can be more effectively used for processing of different properties.

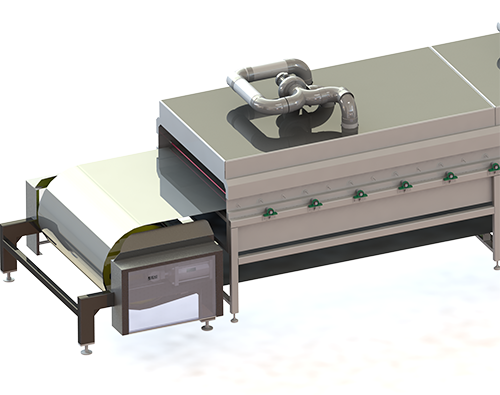

Steel with high temperature and low temperature resistant, be applicable to the environment of 50 degrees to 250 degrees below zero, rubber and resin of high temperature conveyor belt unbearable items can also be moved to send, and can complete the heating operation, in the food drying, baking, steaming, boiling, such as processing, and able to take advantage of high temperature steam wash, can also be used in the freezer, not even when you are in low temperature steel belt deformation, suitable for continuous frozen food in the refrigerator.

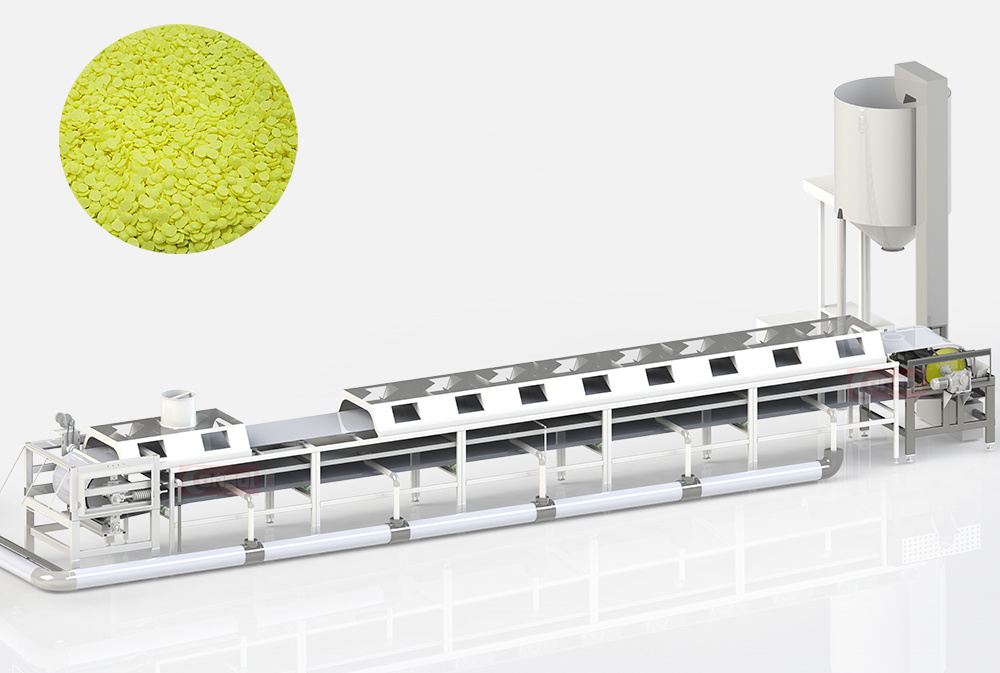

The steel belt is easy to dissipate heat and is sanitary. By natural cooling or spraying water on the back, the cooling molding of tofu, AGAR, Popsicle, milk candy and candy can be realized.

Drying equipment: commonly used in processing raw materials and fruits, vegetables, pet food, phalluses, chewing gum, ground meat and seaweed.

Cooling equipment: chocolate candy, mashed potato, phallus, pectin and other food need a lot of cooling treatment, we have water cooling system, cold air cooling system and air cooling system three different refrigeration technology equipment to provide customers with choice.

Freezing equipment: at present, it is mainly used for frozen fish steaks, hamburger meat, shrimp, seashells, cuttlefish and coffee and tea essence requiring freeze drying.

Storage and delivery equipment: our delivery equipment is superior to other brands in terms of hygiene, cleaning and material collection, and the storage or temporary storage of materials used in conjunction with the delivery system enables more automatic processing and efficient production.

NEWS&EVENT

Steel belt pastillator granulation production line for jewelry wax middle temperature wax

Sulphur Granulation Techniques and Machinery: A Comprehensive Overview

Unleashing the Power of Sulphur Granulation in Plastic Manufacturing

Revolutionizing Plastic Production: Sulphur Granulation Explained

The Ultimate Guide to Sulphur Granulation: Everything You Need to Know

Future-Proofing Manufacturing: The Role of Conveyor Systems

Enhancing Productivity: The Benefits of Conveyor Systems

Streamlining Operations: The Power of Conveyor Systems

Revolutionizing Industrial Automation: The Power of Conveyor Systems

Copyright © 2023 Guangzhou Consol Machinery Equipment Co., Ltd. | All Rights Reserved. 粤ICP备18032917号 SEO Powered by:www.300.cn