-

-

-

BLOG&EVENT

-

ABOUT US

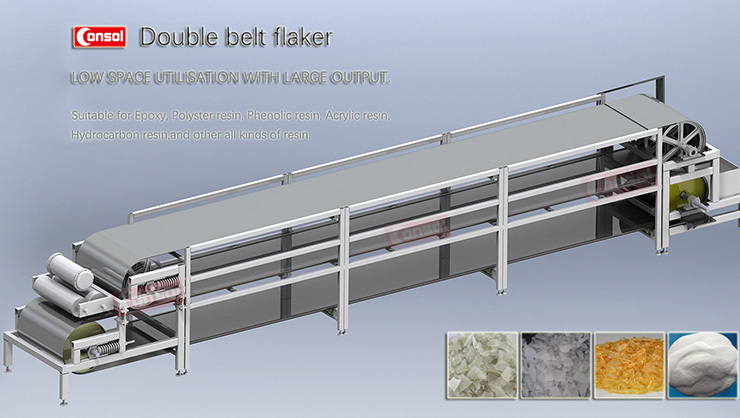

Steel belt double layer flaker for resin chemicals.

Steel belt double layer flaker for resin chemicals.For material heating, cooling, Solidification, broken. For flaker machine, chemical flake, flaking system for chemical industry. For Epoxy, Polyster

Apr 09,2020

Steel belt double layer flaker for resin chemicals.

For certain applications, the double belt cooling system offers significant advantages over a single belt cooler,particularly in terms of increased capacity, as the product is in contact with two cooling belts.The efficiency of this operation is further enhanced by the system's relatively compact dimensions, enabling more to be produced from less floor space.Products such as waxes and resins, which tend to curl away from a single belt, can be processed with complete confidence.It is possible to cool thicker products with a uniform discharge temperature over the whole cross section.

The double belt system also helps to eliminate vapors and fumes between the belts and keep them from the operating area.The product is fed onto the upper surface of the lower belt which carries it to the central cooling zone,where the pressure of the upper belt ensures constant contact with both cooling surfaces.Loading and discharge methods are arranged to suit individual products and can incorporate breaker equipment at the discharge station if required.

Related Posts

Steel belt pastillator granulation production line for jewelry wax middle temperature wax

Rotary belt condensation pastillator granulator&pelletizer is using low melting point characteristic of the material (50 ℃ to 300 ℃), through the feeding head, the liquid material will drop into the upstream moving steel belt,with the continuous spray cooling device set at the bottom of the steel belt (spray type water cooling), materials will be cooled quickly and become solidification in the process of conveying

Contact Us

E-mail

info2@consolbelts.com

Phone/WhatsApp/Wechat

+86 18820135908

19, No.63 jieyuan road, Shawan town, Panyu dist, Guangzhou, China

Request Quote

We will contact you within one working day. Please pay attention to your email.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.