Optimizing Your Granulation Process with Cutting-Edge Steel Belts

In today's competitive industrial landscape, optimizing granulation processes is crucial for manufacturers seeking to enhance productivity and product quality.

Sep 15,2025

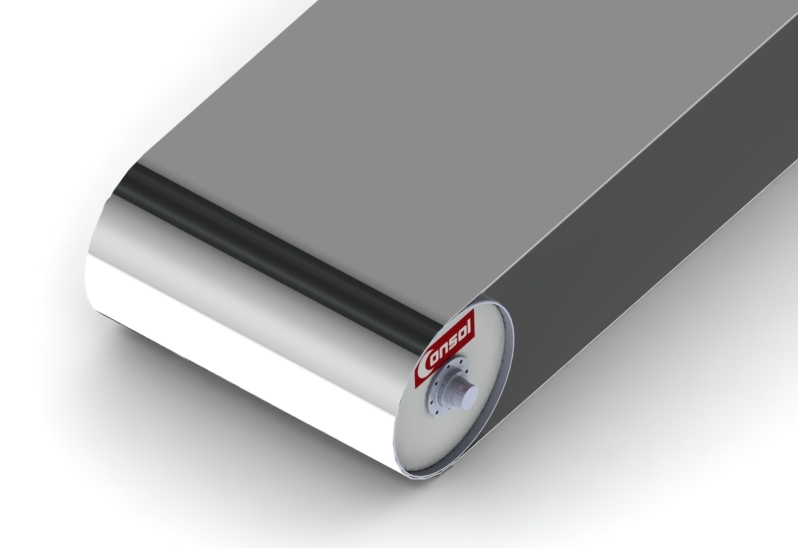

In today's competitive industrial landscape, optimizing granulation processes is crucial for manufacturers seeking to enhance productivity and product quality. As a leading steel belt manufacturer, Consol has revolutionized the industry with its innovative Stainless Steel Belt AS1200. This advanced metal conveyor belt wholesale solution is designed to meet the demanding requirements of petrochemical and other industrial applications. By incorporating cutting-edge technology and superior materials, the AS1200 offers unparalleled performance in handling a wide range of materials, from sulphur and paraffin wax to urea and hot melt adhesives.

Table of contents:

The Role of Stainless Steel Belts in Achieving Consistent Product Quality

Streamlining Operations: Integrating AS1200 Metal Conveyor Belts into Your Facility

Maintenance Best Practices for Longevity of Stainless Steel Conveyor Systems

Customization Options: Tailoring Steel Belts for Specific Granulation Needs

The Role of Stainless Steel Belts in Achieving Consistent Product Quality

The Stainless Steel Belt AS1200 plays a pivotal role in ensuring consistent product quality throughout the granulation process. As a premier Stainless Steel Belt supplier, Consol has engineered this metal conveyor belt wholesale product to deliver superior thermal conductivity, facilitating efficient heat transfer and energy savings. This feature is particularly crucial when working with temperature-sensitive materials like sulphur bentonite and resin. The exceptional cooling efficiency of the AS1200 promotes uniform solidification, resulting in high-quality granules that meet stringent industry standards. By choosing a reputable steel belt manufacturer, businesses can significantly improve their output quality and operational efficiency.

Streamlining Operations: Integrating AS1200 Metal Conveyor Belts into Your Facility

Integrating the AS1200 metal conveyor belt wholesale into existing facilities is a seamless process that can dramatically streamline operations. The versatile design of this stainless steel conveyor belt allows for easy installation and compatibility with various granulation systems. As a trusted Stainless Steel Belt supplier, Consol ensures that the AS1200 is scalable to accommodate future growth, making it a wise long-term investment for businesses of all sizes. The belt's ability to handle a diverse range of materials provides flexibility in production, allowing manufacturers to adapt quickly to changing market demands without the need for extensive equipment modifications.

Maintenance Best Practices for Longevity of Stainless Steel Conveyor Systems

To maximize the lifespan and performance of the AS1200 stainless steel conveyor belt, implementing proper maintenance practices is essential. The exceptional corrosion resistance of the belt, a hallmark of quality from a reputable steel belt manufacturer, significantly reduces wear and tear in harsh industrial environments. Regular inspections, proper cleaning protocols, and timely adjustments are key to maintaining optimal performance. Consol, as a leading Stainless Steel Belt supplier, offers comprehensive after-sales support, including guidance on maintenance best practices, ensuring that clients can fully leverage the durability and efficiency of their metal conveyor belt wholesale investment.

Customization Options: Tailoring Steel Belts for Specific Granulation Needs

Understanding that each granulation process has unique requirements, Consol offers customization options for the AS1200 stainless steel conveyor belt. As an experienced steel belt manufacturer, they work closely with clients to tailor solutions that address specific operational challenges. Whether it's adjusting the belt width, modifying the surface texture, or incorporating special features for enhanced cooling or material handling, the flexibility of the AS1200 design allows for precise customization. This level of adaptability ensures that businesses can optimize their granulation processes to achieve maximum efficiency and product quality, regardless of the materials being processed.

In conclusion, the Stainless Steel Belt AS1200 represents a significant advancement in granulation technology, offering a combination of superior thermal conductivity, exceptional corrosion resistance, and enhanced cooling efficiency. As a leading steel belt manufacturer and Stainless Steel Belt supplier, Consol has positioned the AS1200 as a critical component for businesses looking to enhance their granulation processes. By choosing this advanced metal conveyor belt wholesale solution, manufacturers can benefit from improved product quality, increased operational efficiency, and the flexibility to adapt to future production needs. With its robust design, customization options, and comprehensive support, the AS1200 is poised to set new standards in industrial granulation, helping businesses stay competitive in an ever-evolving market.

Related Posts

Steel belt pastillator granulation production line for jewelry wax middle temperature wax

Rotary belt condensation pastillator granulator&pelletizer is using low melting point characteristic of the material (50 ℃ to 300 ℃), through the feeding head, the liquid material will drop into the upstream moving steel belt,with the continuous spray cooling device set at the bottom of the steel belt (spray type water cooling), materials will be cooled quickly and become solidification in the process of conveying

Contact Us

E-mail

info2@consolbelts.com

Phone/WhatsApp/Wechat

+86 18820135908