Contact Us

E-mail info2@consolbelts.com

Phone/WhatsApp/Wechat

+86 18820135908

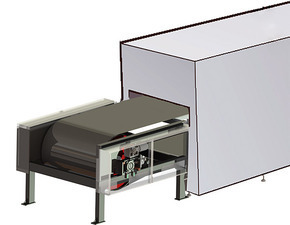

Stainless Steel Belt AS1200

Stainless steel belt AS1200 is very suitable for granulation for petrochemicals like sulphur, sulphur bentonite, paraffin wax, resin, pitch, urea, hot melt adhesive...

Стальная лента

Stainless steelbelt granulation/Pastillator

Free flowing particles have uniform size and mass for subsequent transportation, storage and transportation.Steel belt has large heat transfer area and small energy consumption,outstanding corrosion resistance ability of ASS1200 is suitable for sulphur granulation,wax granulation,resin granulation,pitch granulation,chemicals granulation,fertilizer granulation and so on.

Description of the Granulation/Pastillator Process

The molten product is pumped by a heatable pump via heated pipes to the feeder of the steel belt cooler in a constant adjustable rate.

The main parts of the feeder are: a heated, fixed cylindrical body (stator) which has a recess for product flow for its entire length and an external tube which rotates around the internal stator. This external tube has many holes drilled in a regular pattern.

As soon as each hole passes the recess in the stator, a small amount of product leaves the dropformer and is deposited onto the belt to be cooled in the form of a pastille.

The heat released during cooling and solidification is carried off by the stainless steel belt. The excellent thermal conductivity of the steel belt supports this process.

Cooling water is sprayed against the underside of the steel belt through eccentric nozzles which ensures uniform wetting and thereby uniform cooling. The excellent thermal conductivity of the steel belt is a special advantage for heat removal during cooling and solidification in this process.

Fresh or recycled, recooled water may be used continuously in the cooling water spraying system.

After solidification the pastilles are scraped off from the steel belt by a discharge knife and passed on to further processing.

Unmatched Efficiency and Thermal Conductivity

The Stainless Steel Belt AS1200 from Guangzhou Consol Machinery Equipment Co., Ltd is engineered to redefine efficiency in industrial granulation processes. This stainless steel conveyor belt is designed with superior thermal conductivity, ensuring optimal heat transfer and energy savings. Whether you're working with petrochemicals like sulphur, sulphur bentonite, paraffin wax, resin, pitch, or urea, the AS1200 guarantees consistent performance. Its robust construction allows it to withstand high temperatures and corrosive environments, making it an indispensable component in your production line. The metal conveyor belt design enhances the cooling process, ensuring uniform solidification and high-quality output.

Built for Precision and Durability

Precision and durability are at the core of the Stainless Steel Belt AS1200. This steel belt is crafted to deliver exceptional reliability, minimizing downtime and maintenance costs. Its seamless surface and uniform thickness ensure smooth operation, reducing wear and tear on machinery. The AS1200's corrosion-resistant properties make it ideal for long-term use in demanding industrial settings. Its ability to handle a wide range of materials, from hot melt adhesives to fertilizers, showcases its versatility. The stainless steel conveyor belt is not just a component; it's a critical asset that enhances the overall efficiency and productivity of your operations.

Scalable Design for Future Growth

As industries evolve, so do their demands. The Stainless Steel Belt AS1200 is designed with scalability in mind, ready to meet the growing needs of your business. Its adaptable design allows for easy integration into existing systems, making it a future-proof investment. Whether you're expanding your production capacity or diversifying your product range, this metal conveyor belt can accommodate your requirements. Its compatibility with various granulation processes ensures that it remains relevant as your business grows. Trust in the AS1200 to provide the reliability and performance you need to stay ahead in a competitive market. With its steel belt technology, you're not just investing in a product; you're investing in the future of your business.

Product Advantages

1.Superior Thermal Conductivity

The Stainless Steel Belt AS1200 excels in thermal conductivity, ensuring efficient heat transfer for petrochemical applications. This stainless steel conveyor belt optimizes energy savings by maintaining consistent temperatures, crucial for processes involving sulphur, paraffin wax, and urea. Its robust design withstands high temperatures, making it a reliable choice for demanding environments.

2.Exceptional Corrosion Resistance

Designed to endure harsh industrial conditions, the metal conveyor belt AS1200 offers outstanding corrosion resistance. This feature extends the lifespan of the steel belt, reducing maintenance costs and downtime. Ideal for handling corrosive materials like sulphur bentonite and resin, it ensures long-term operational efficiency.

3.Enhanced Cooling Efficiency

The stainless steel conveyor belt design of the AS1200 enhances the cooling process, promoting uniform solidification of materials. This results in high-quality output, essential for granulation processes. The steel belt technology ensures that cooling is consistent, improving product quality and reducing waste.

4.Versatile Material Handling

The Stainless Steel Belt AS1200 is versatile, capable of handling a wide range of materials from hot melt adhesives to fertilizers. This adaptability makes it a valuable asset in diverse industrial settings, ensuring that your production line remains efficient and productive, regardless of material changes.

5.Future-Proof Scalability

With its scalable design, the metal conveyor belt AS1200 is ready to meet the evolving needs of your business. It integrates seamlessly into existing systems, supporting expansion and diversification. Investing in this stainless steel conveyor belt means securing a component that grows with your business, ensuring sustained performance and competitiveness.

About CONSOL

Industry Positioning

CONSOL is a leading international enterprise specializing in steel belts and steel belt driving systems, providing reliable solutions to customers worldwide.

Core Manufacturing Capabilities and Quality Assurance

Product Range: We offer a diverse array of steel belts, including carbon steel belts, stainless steel belts, perforated steel belts, super mirror steel belts, precision steel belts, and martensitic stainless steel belts.

Application Areas: Our products are utilized across various industries such as oil & gas, chemical, food, precision machinery, film casting, woodworking, and composite industries.

Quality Commitment: We adhere to stringent quality standards to ensure our products meet the highest industry requirements.

Production Strength

Located in Guangzhou, the heart of the Pearl River Delta, CONSOL has established a robust manufacturing base, enabling us to serve clients efficiently across the globe.

Sustainability Measures

Our steel belts are designed for durability and recyclability, contributing to sustainable industrial practices.

Customer Collaboration Process

We have built a comprehensive sales and after-sales service system, coordinating installation services near our clients' facilities to ensure optimal service quality.

Global Service Capability

Over the past decade, CONSOL has exported products to more than 30 countries, including the USA, Russia, Canada, Korea, South Africa, Iran, Turkey, Ukraine, Saudi Arabia, Spain, Holland, Brazil, Malaysia, Thailand, India, Pakistan, the Philippines, Indonesia, and Vietnam.

FAQ

Who are we?

CONSOL is an international enterprise focusing on steel belts and steel belt driving systems, committed to providing reliable solutions to customers worldwide.

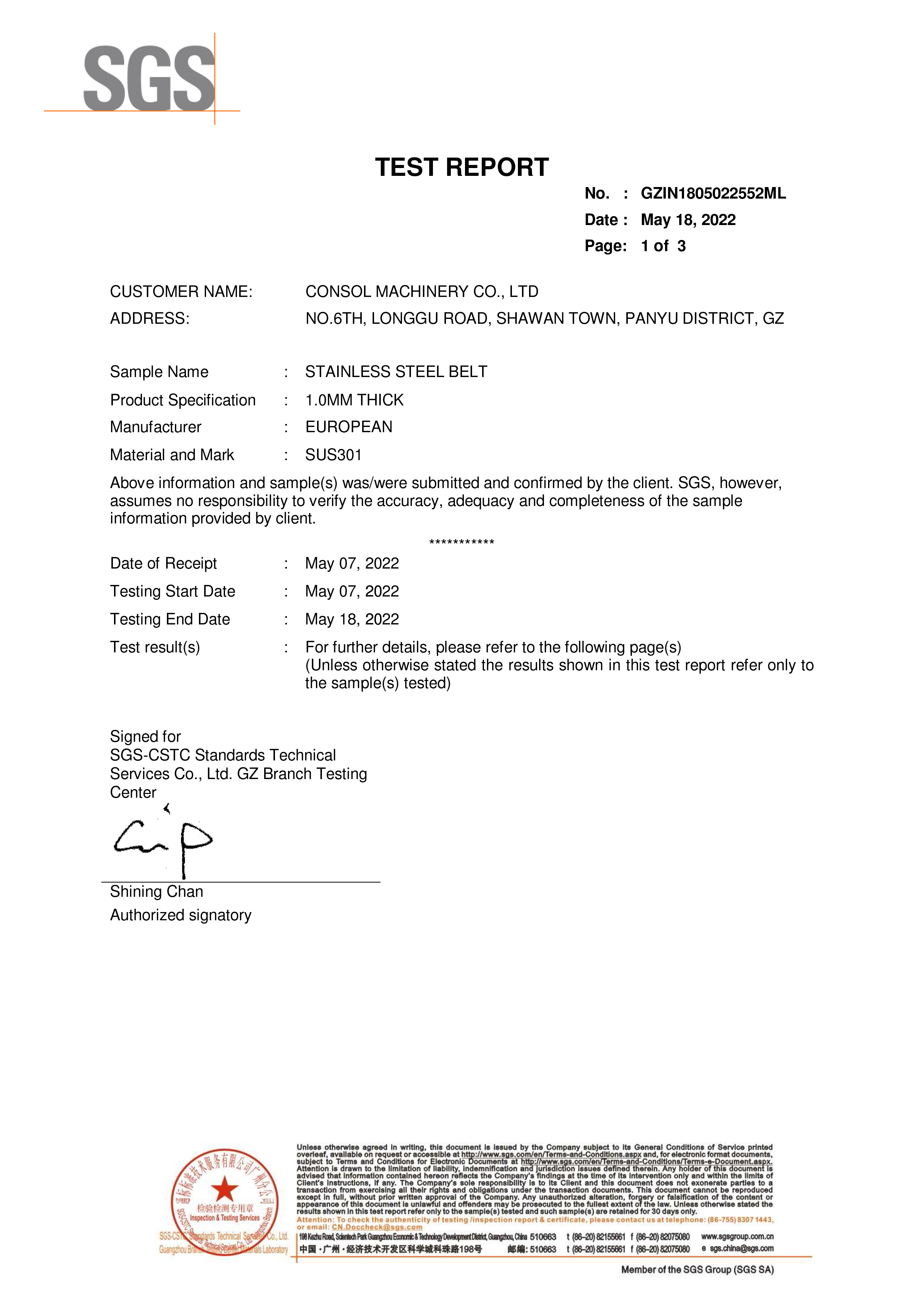

How can we guarantee quality?

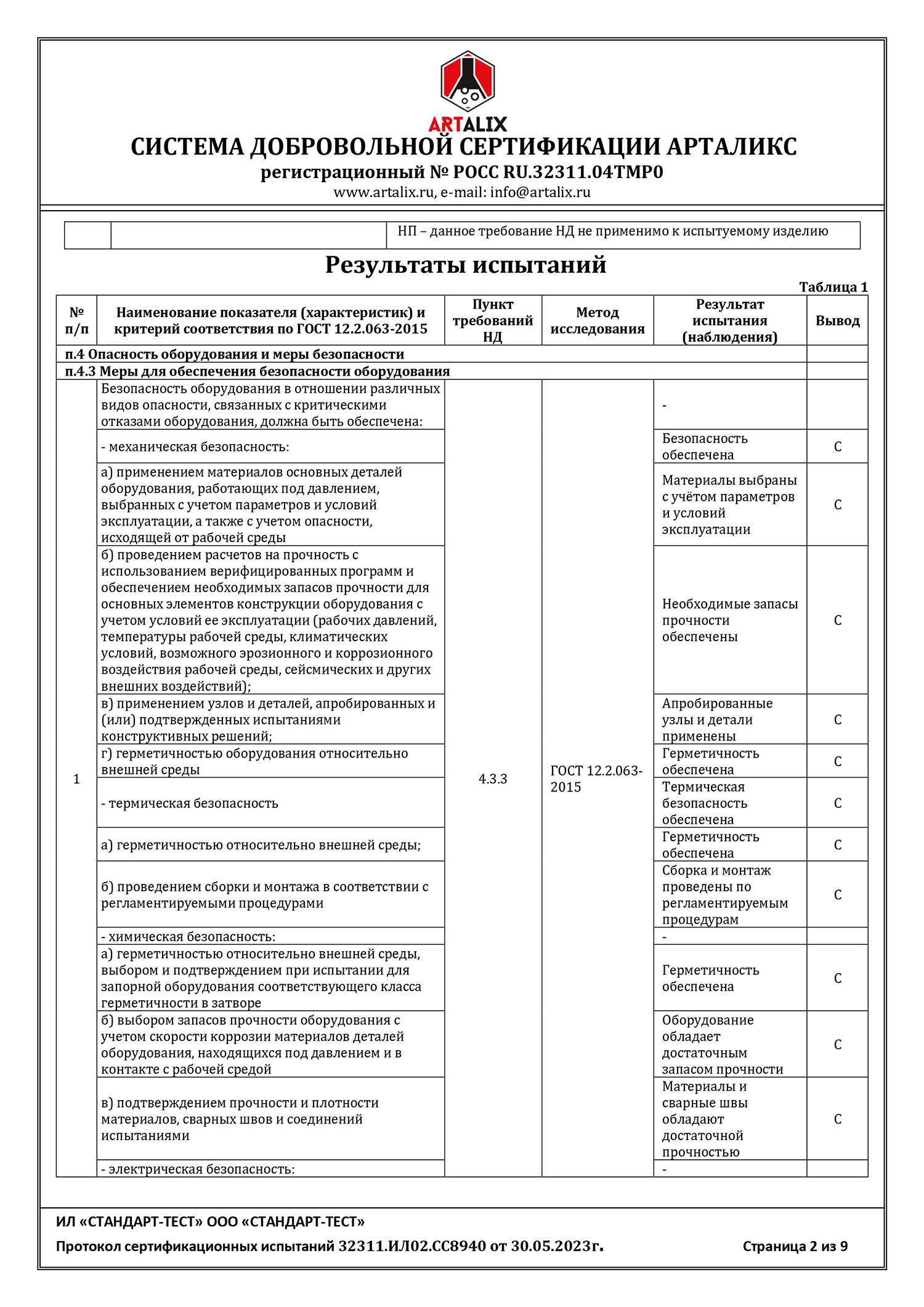

We adhere to strict quality control processes and hold certifications such as SGS, CE, and ISO 9001 to ensure our products meet international standards.

What can you buy from us?

Our product offerings include various types of steel belts and conveyor systems suitable for multiple industrial applications.

Why should you buy from us and not from other suppliers?

With a decade of experience exporting to over 30 countries and a commitment to quality and customer service, CONSOL stands out as a reliable partner for your industrial needs.

What services can we provide?

We offer comprehensive services, including after-sales support, seamless welding technology, edge shaping, conveyor system rebuilding, and V-rope sticking, ensuring our clients receive end-to-end solutions.

OUR CAPABILITY

CONSOL is an international enterprise focusing on steel belt and steel belt driving system.

Keyword:

Related Products