Pastillator vs. Traditional Granulator Machine: Which One Fits Your Production Line?

Industrial manufacturing processes require superior equipment to ensure efficiency, uniformity, and reliability. Whether you’re producing fertilizers, resins, or other chemical products, choosing between a pastillator and a traditional granulator machine can significantly impact your production line.

May 16,2025

Industrial manufacturing processes require superior equipment to ensure efficiency, uniformity, and reliability. Whether you’re producing fertilizers, resins, or other chemical products, choosing between a pastillator and a traditional granulator machine can significantly impact your production line. Both machines are designed to facilitate granulation, but their unique features and operation methods make them suitable for different applications. This blog will explore key comparisons, including output uniformity, maintenance requirements, and signals that it might be time to upgrade your current granulation equipment. Whether you're browsing for a reliable industrial granulator supplier or considering adopting a high-efficiency pastillator machine, this guide aims to help you make an informed decision that enhances your operations.

Table of contents:

Comparing Output Uniformity and Cooling Methods

Maintenance Needs: Pastillator vs. Conventional Granulators

When to Upgrade: Signs Your Current Granulator Machine Is Holding You Back

Comparing Output Uniformity and Cooling Methods

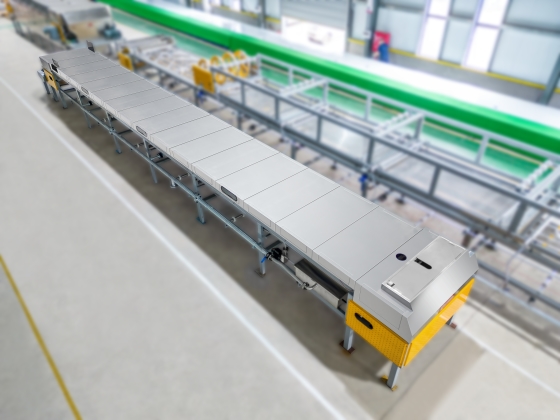

One of the most noticeable differences between a pastillator machine and a traditional granulator lies in their approach to output uniformity and cooling techniques. A pastillator is lauded for producing highly uniform and stable granules. This precision is particularly advantageous in industries like food production or specialty chemicals that demand consistent product sizes. The secret to a pastillator's success lies in its method of dripping liquid material onto a steel belt, where the granules are rapidly cooled and solidified. Innovations, such as those seen in Consol's pastillator machines, enable efficient spray cooling that prevents deformation and ensures stability.Traditional granulators, on the other hand, use equipment that turns large material chunks into smaller granules. While effective for bulk processing, granulators often yield products with varying granule sizes, which can make it challenging to guarantee consistency. For instance, in chemical and resin processing, these inconsistencies may result in inefficiencies during downstream use. Hence, businesses requiring precision and uniformity often lean towards the pastillator instead.

Maintenance Needs: Pastillator vs. Conventional Granulators

Maintenance is another major factor to consider while choosing between the two options. Pastillators tend to involve fewer moving components than traditional granulators, making them easier to maintain overall. This simplicity leads to reduced wear-and-tear, lower long-term costs, and minimal downtime due to maintenance. Features like the use of corrosion-resistant steel belts, as offered by leading granulator manufacturers such as Consol, ensure longevity even in challenging production environments. Additionally, pastillators are built with efficiency and reliability in mind, making them a strong choice for businesses that want to minimize interruptions. Conversely, traditional granulators require more intensive upkeep. Their mechanical configurations feature cutting blades and rotors, which often require regular servicing to maintain efficiency. Over time, the costs of replacing parts, coupled with labor-intensive maintenance, can add up significantly. Additionally, granulators are susceptible to clogging, especially in high-capacity operations. This can extend downtime and increase costs, making it less ideal for businesses operating on tight schedules or those aiming for optimized workflows.

When to Upgrade: Signs Your Current Granulator Machine Is Holding You Back

Deciding when to upgrade your equipment is crucial for maintaining competitive production capabilities. If your current granulator machine shows signs like declining output quality, frequent downtime, or high energy consumption, it may be time to explore alternatives. Reduced product uniformity can hurt your brand reputation, while persistent malfunctions and maintenance delays disrupt production. Over time, these inefficiencies can snowball into greater financial losses and missed opportunities. Additionally, older granulators often struggle with scaling production demands and consume more energy, increasing costs dramatically over time. Upgrading to advanced pastillator machines, like those from Consol, offers reliable, large-scale production with consistent output and energy-efficient operations, ensuring your processes stay efficient and competitive. With enhanced features such as precision control and lower maintenance needs, modern pastillators provide a long-term solution for reducing waste, improving product consistency, and keeping up with market demands.

Ultimately, staying in tune with your production line’s needs and recognizing these signals can help you avoid costly inefficiencies, improve productivity, and optimize your operations. Whether you’re considering a new pastillator machine, upgrading existing equipment, or searching for a top industrial granulator supplier, making a well-informed choice ensures long-term benefits, consistent output quality, and smoother workflows for your production line.

Related Posts

Steel belt pastillator granulation production line for jewelry wax middle temperature wax

Rotary belt condensation pastillator granulator&pelletizer is using low melting point characteristic of the material (50 ℃ to 300 ℃), through the feeding head, the liquid material will drop into the upstream moving steel belt,with the continuous spray cooling device set at the bottom of the steel belt (spray type water cooling), materials will be cooled quickly and become solidification in the process of conveying

Contact Us

E-mail

info2@consolbelts.com

Phone/WhatsApp/Wechat

+86 18820135908