Pastillator

Product description

E-mail Us:info2@consolbelts.com

Product Details

What is pastillator?

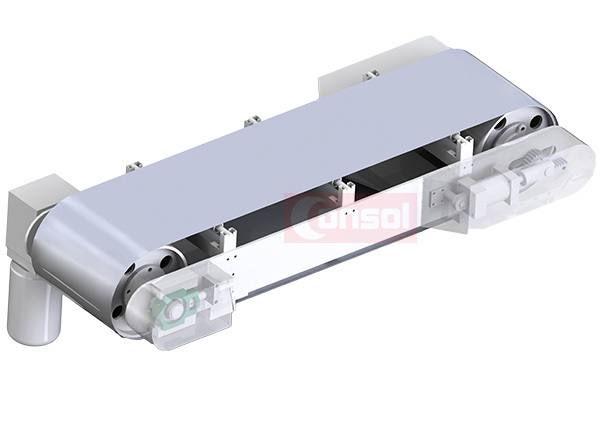

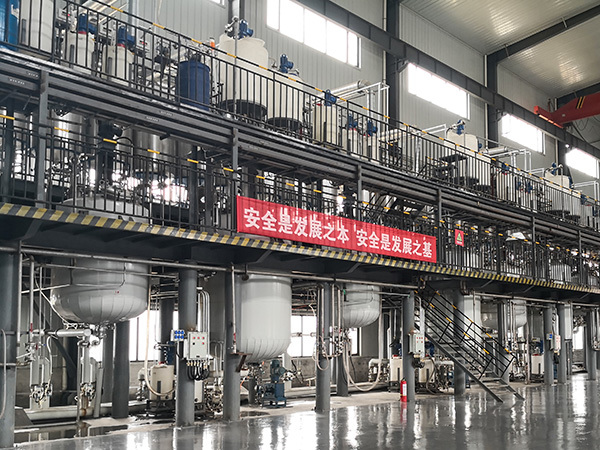

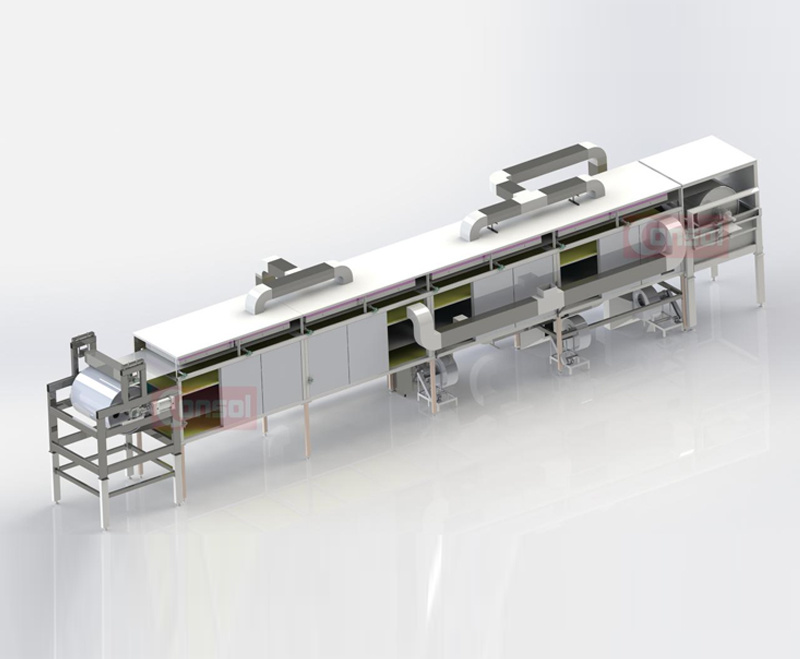

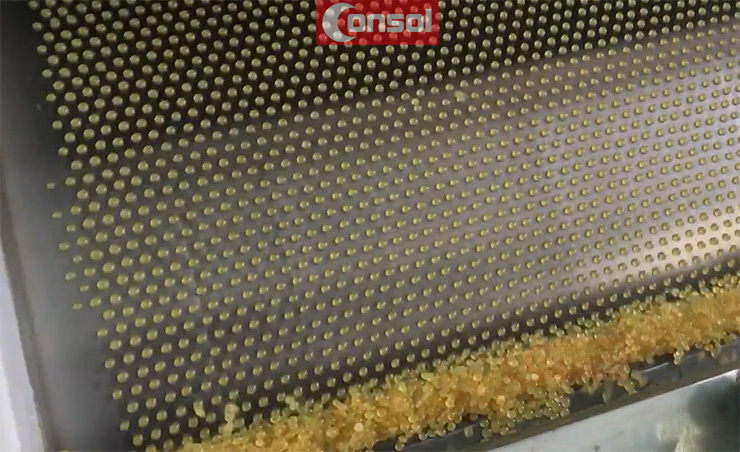

Pastillator, is also named as granulator, or steel belt granulation system,which is widely used in chemical industry.

The Pastillator is an innovative equipment designed for the efficient and precise production of solid materials in various industries. This specialized machine is widely used in industries such as chemicals, petrochemicals, pharmaceuticals, and food processing, offering exceptional performance and value.

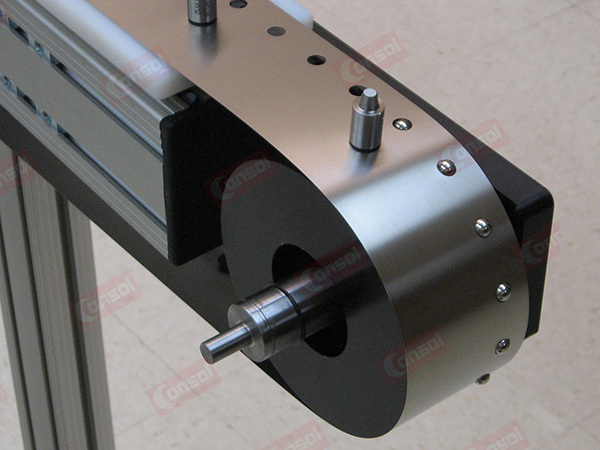

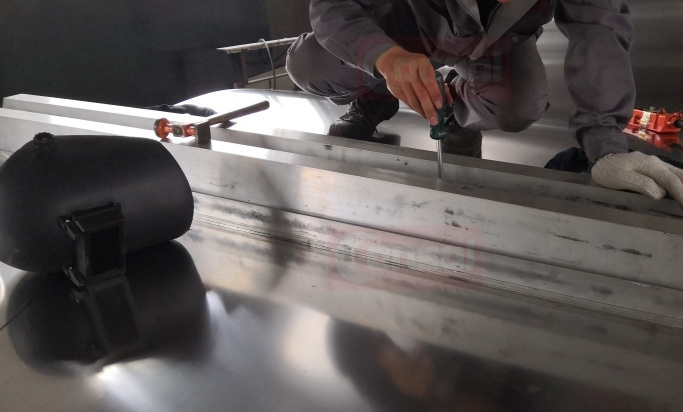

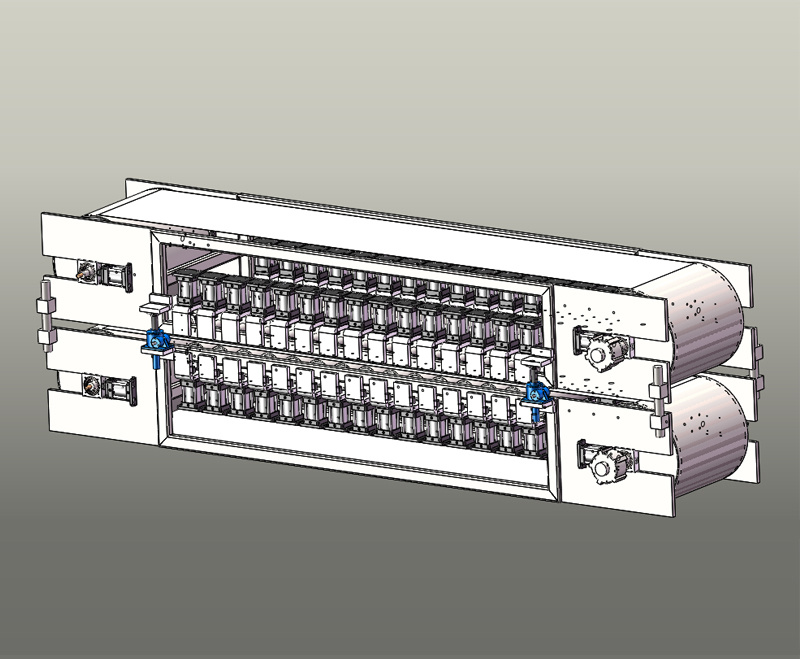

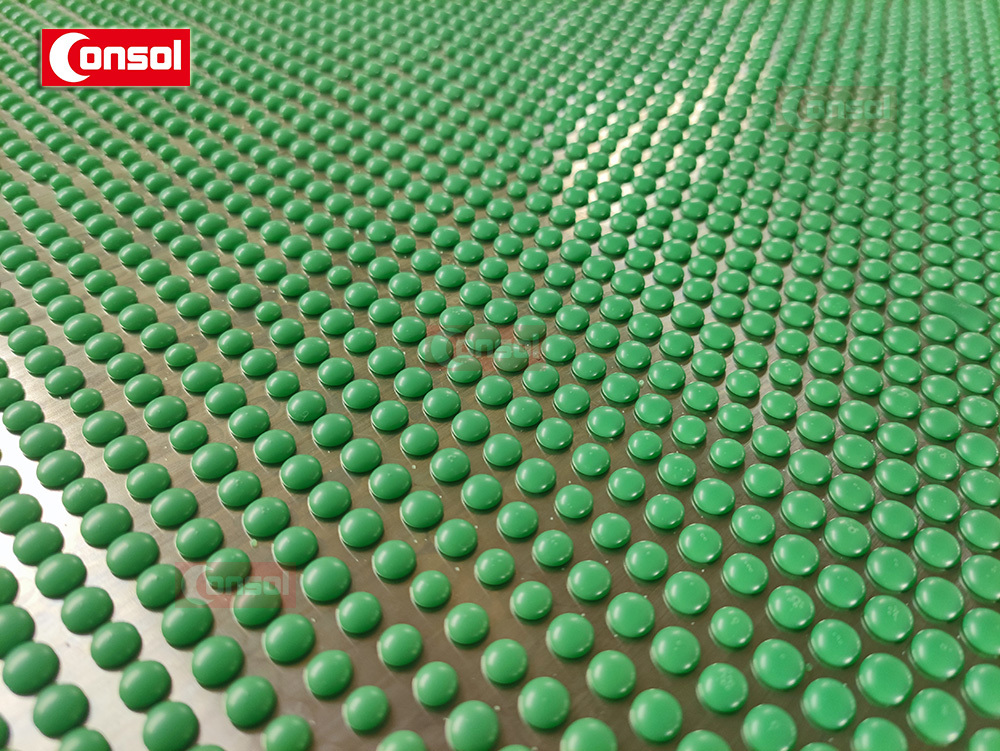

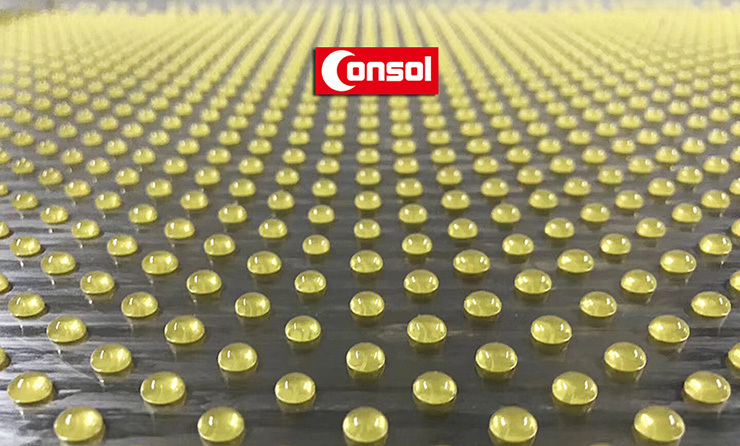

The Pastillator is equipped with state-of-the-art technology and features a robust and durable construction, ensuring long-lasting operation and reliability. Its precision-engineered design allows for the controlled and uniform solidification of liquid or viscous materials into small, solid particles known as pastilles.

One of the standout features of the Pastillator is its high production capacity and efficiency. With adjustable parameters and customizable settings, this machine can handle a wide range of materials and produce pastilles with consistent size, shape, and quality. Its advanced cooling system ensures rapid solidification of the material, maximizing productivity and minimizing downtime.

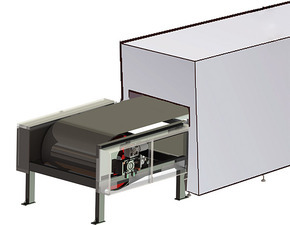

The versatility of the Pastillator makes it ideal for a variety of applications. In the chemicals industry, it is commonly used for the production of various waxes, resins, and polymers. In the petrochemical industry, it is employed for the creation of solidified additives and catalysts. In the pharmaceutical and food industries, it enables the production of granules or pellets easier handling and dosage.

The Pastillator’s precise control over the solidification process ensures the desired quality and characteristics of the final product. Its efficient cooling system prevents overheating and maintains optimal operating conditions, resulting in consistent and high-quality pastilles.

Moreover, the Pastillator offers seamless integration into existing production lines and can be customized to meet specific requirements. Its user-friendly interface and intuitive controls simplify operation and maintenance, allowing for smooth and uninterrupted production processes.

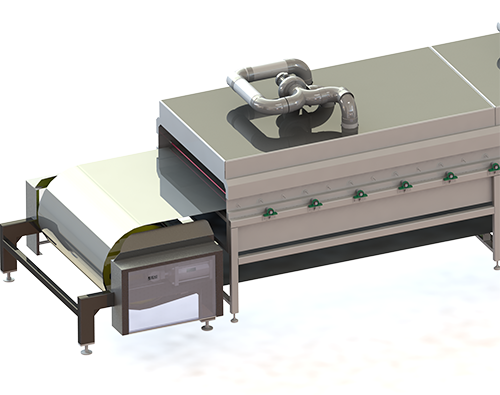

In summary, the Pastillator by Consol Steel Belt is a highly efficient and versatile equipment for the production of solid materials. With its advanced technology, high production capacity, and precision control, it delivers consistent and high-quality pastilles for a wide range of industries. Optimize your production processes with the reliable performance and versatility of the Pastillator, ensuring efficiency and productivity in your operations.

Pastillator

Related Products

Main application of film industry The main application examples are: environmental water-soluble membrane; electronic material PI membrane; semi-permeable membrane;

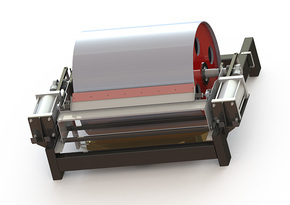

Steel belt cooler pastillator is suitable for granlation and flake of resin, sulfur, wax, chocolate, chemicals,foods.Good corrosion resistance, long service life, suitable for a variety of materials.

NEWS&EVENT

Steel belt pastillator granulation production line for jewelry wax middle temperature wax

Unlocking the Secrets of Resin Solidification in Rubber Processing

Understanding Resin Solidification: A Key Process in Rubber Compounding

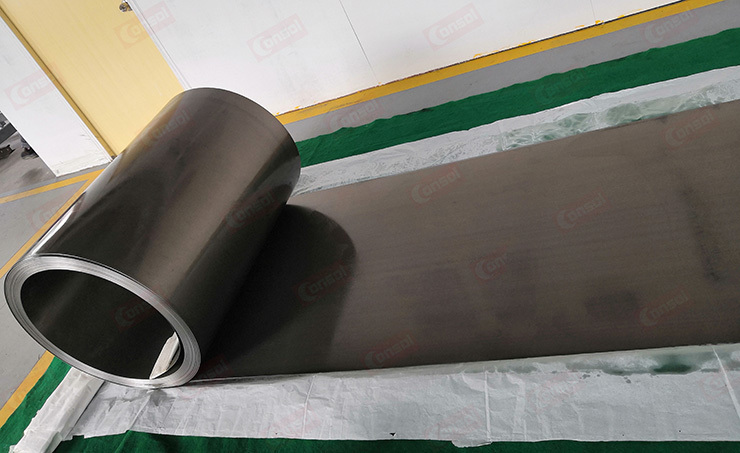

Key Factors to Consider When Selecting AS1200 Stainless Steel Belts

Understanding Stainless Steel Belt AS1200: Applications and Benefits

Unlocking the Secrets of Chocolate Granulation in Rubber Processing

Understanding Chocolate Granulation in Rubber Processing

Product message

CONVEY SYSTEM

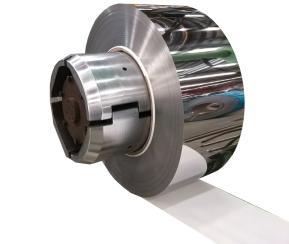

STEEL BELT

Copyright © 2023 Guangzhou Consol Machinery Equipment Co., Ltd. | All Rights Reserved. 粤ICP备18032917号 SEO Powered by:www.300.cn