-

-

-

BLOG&EVENT

-

ABOUT US

Contact Us

E-mail info2@consolbelts.com

Phone/WhatsApp/Wechat

+86 18820135908

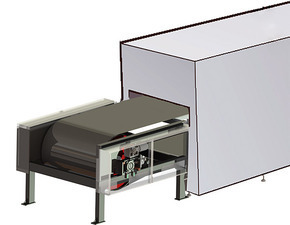

Bake oven conveyor

A complete set of bake oven conveyor system should include driving-tensioning ends, steel belt, auto-tracking system, graphite bar, cast iron skid bars, guide roller...

Транспортная система

Brief introduction of tunnel bake oven

Tunnel bake oven (food processing) is a tunnel type mechanical equipment that completes food baking through heat conduction, convection, and radiation. The oven body is generally very long, with a minimum of 6 meters and a length of 60 to 80 meters. The baking chamber is a long and narrow tunnel with a width generally ranging from 80cm to 140cm. There is a continuous conveyor system in the tunnel. When the food is roasted, the food produces relative movement between the conveying chain plate, steel belt and the electric heating element or the direct-fired burning rod. So as to complete the work of uniform baking and conveying. This type of oven can be produced continuously, has high production efficiency, saves manpower, and has stable baking quality. The tunnel bake oven is mainly used in industrialized food enterprises, and is characterized by continuous or intermittent baking in large quantities. Usually rated power input>24KW, operated by full-time personnel. Generally, according to different heat sources, there are electric tunnel bake ovens, gas tunnel bake ovens or natural gas tunnel bake ovens. The manufacturer can customize the length and width at will according to the production volume of the tunnel bake oven user. Scope of application: bread (staple bread, prepared bread, etc.), cakes, biscuits, snacks, egg yolk pie, moon cakes, etc.

The tunnel bake oven is a large-scale equipment that provides continuous baking and can be equipped with production line operations. It has the characteristics of high production efficiency, labor saving, and stable baking quality.

According to the different baking time requirements of various products, intelligent control can be implemented through the PLC intelligent control system. Transmission frequency conversion speed regulation can realize stepless speed change.

OUR CAPABILITY

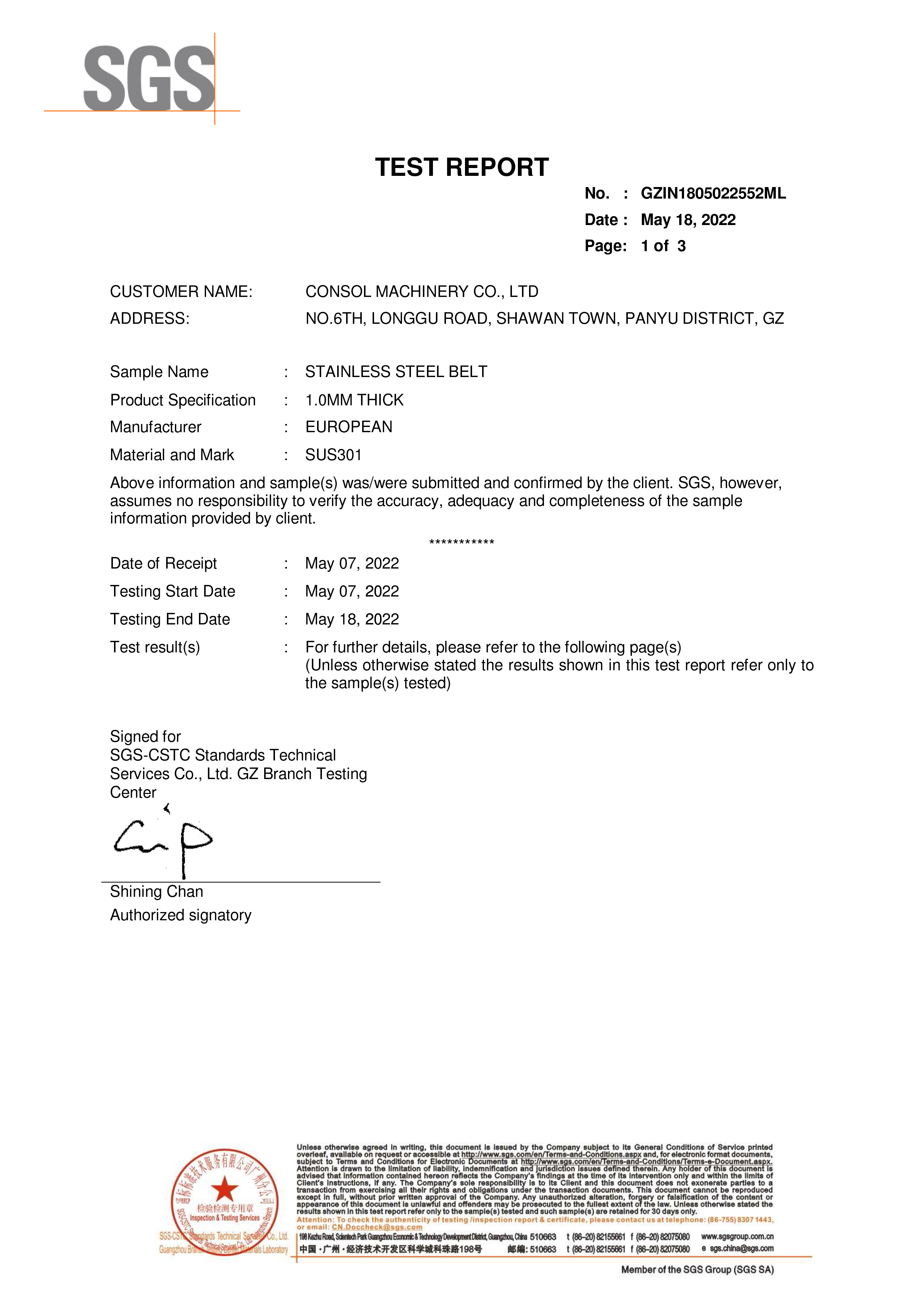

CONSOL is an international enterprise focusing on steel belt and steel belt driving system.

Keyword:

Related Products

19, No.63 jieyuan road, Shawan town, Panyu dist, Guangzhou, China

Request Quote

We will contact you within one working day. Please pay attention to your email.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.