-

-

-

BLOG&EVENT

-

ABOUT US

Contact Us

E-mail info2@consolbelts.com

Phone/WhatsApp/Wechat

+86 18820135908

Chocolate granulation

The core technology in candy/chocolate granulating production process

Транспортная система

The core technology in candy/chocolate production process

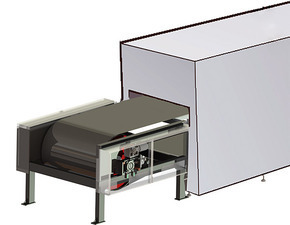

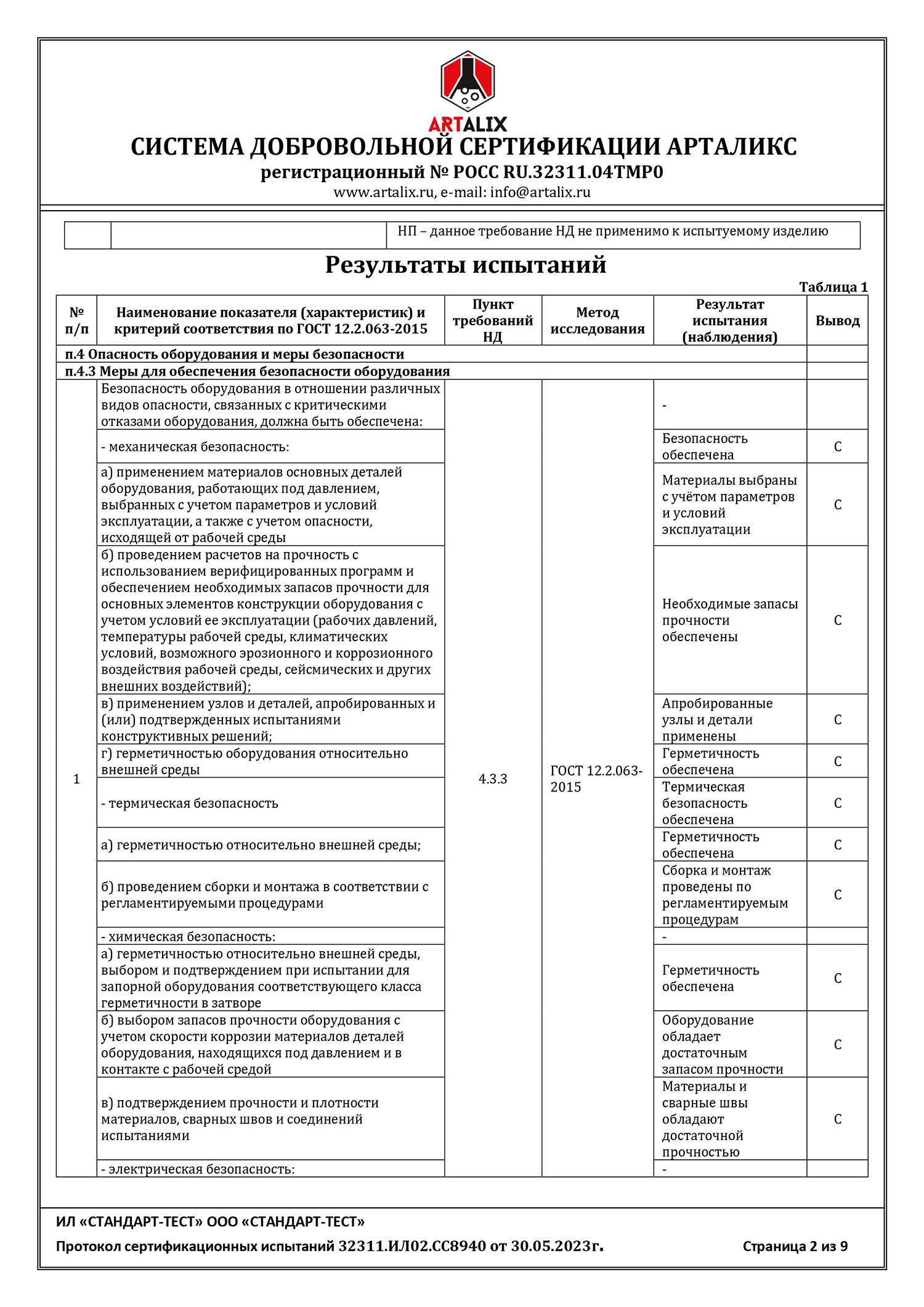

We can product almost any length/width steel belt,apply to the system from material to production.Not only we offer steel belt replacing service,but also support steel conveyor system for equipment manufacturer including drums,supports,tracking devices and clean scrapers.

Cooling/Curing

We can design,produce and install all kinds of cooling systems,which are clean and efficiency by using cooling air or cooling water.

Granulation

Our chocolate granulation system is a continues solution from melting to cure,it can achieve mass production for quality granulation,and adapt for high viscosity product up to 50,000mPas,sizes from 3 to 15mm.

Pouring

The steel belt also can be used for curing caramel and candy.Furthermore,we provide steel belt for equipment manufacture,but also provide the whole system equipment including feeding device,strip making device and cutter/flaker.

OUR CAPABILITY

CONSOL is an international enterprise focusing on steel belt and steel belt driving system.

Related Products

19, No.63 jieyuan road, Shawan town, Panyu dist, Guangzhou, China

Request Quote

We will contact you within one working day. Please pay attention to your email.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.