Contact Us

E-mail info2@consolbelts.com

Phone/WhatsApp/Wechat

+86 18820135908

Resin solidification

Suitable for all kinds of resin rosin like Hydrocarbon resin, Phenolic resins, Epoxy resins, Ink resins, Gum resins...

Транспортная система

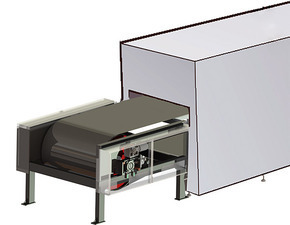

Granulator for Resins

Hydrocarbon resin:mainly for diapers

Phenolic resins:for cable insulation, adhesives and mineral wool

Epoxy resins:electronic industry

Ink resins:printing industry

Gum resins:chewing gum, glue for tiles

Product Dimensions

Pastille Diameter:7 - 8 mm

Pastille Height:3.5 mm

Pastille Weight:0.12 g

Capacity

Specific Capacity:70-100 kg/m²h

Machine Capacity:500KG-3500 KG/H

Physical Properties:

Feed Temperature:160 to 250°C

Viscosity:500 to 40.000mPas

Discharge Temperature:30 to 40 °C

Required Cooling Time:0.8 to 1min

Details

- fully heatable gear pump (pressure up to 15 bar g)

- upstream pre-/fine filter (down to mesh 20microns)

- product heat exchanger for fast heat up of product

- exhaust air extraction

- hood with collection channel for sublimated fumes

- shell heating to avoid fibre generation

- heatable drum and 2 water zones for smooth cooling

- flushing tube/circuit for effective cleaning of system

- powdering system for product (i.e. calcium stearate)

Targeted Production Solution for Resin Pastillation

Designed for industrial processors of hydrocarbon, phenolic, epoxy, ink, gum resins, and rosin, this pastillator machine converts liquid resins into uniform solid pastilles. Its configuration suits manufacturers requiring consistent pellet size for improved handling and dosing in downstream applications. The system facilitates controlled resin flow with a fully heatable gear pump, ensuring process reliability for resin producers, adhesives manufacturers, and composite material plants. This granular solidification supports operators needing steady output within 500 to 3500 kg/h capacity ranges, optimizing pellet uniformity and minimizing handling variability.

Technical Attributes Enabling Precision and Efficiency

Equipped with a gear pump capable of up to 15 bar g, the machine maintains controlled pressure and flow, integral to resin pastillation. The system incorporates upstream filtration to 20 microns for material purity and a product heat exchanger to accelerate heating cycles. The heatable drum with dual water cooling zones achieves stable thermal regulation critical for maintaining pastille integrity. Features like shell heating reduce fiber contamination, while a flushing circuit and powdering system allow for additive incorporation such as calcium stearate to enhance flow properties. The pastilles produced measure 7–8 mm in diameter and weigh approximately 0.12 g, aligning with industry standards for granulator machines.

Application Scope and Operational Benefits in Resin Processing

This resin solidification line supports diverse resin processing sectors including cable insulation with phenolic resins, electronics using epoxy pastillation, printing with ink resins, and mineral wool adhesive production via rosin. Its steel belt cooling offers rapid pellet cooling ensuring minimal cycle times and consistent quality, a crucial factor for high-throughput plants. By delivering uniform pellets through wax granulation and sulphur granulation-related processes, the system integrates seamlessly into continuous production lines demanding stringent control and reproducibility. It enables manufacturers to enhance yield, reduce waste, and streamline dosing in compound formulations.

Product Advantages

Optimized Design for Modular Integration and Control

The structural design incorporates a fully heatable gear pump and a heatable drum equipped with two precision water cooling zones, facilitating tight thermal management essential for consistent resin solidification. The integration of a powdering system alongside a flushing tube provides modularity, allowing additive incorporation and simplified cleaning cycles. The system’s upstream fine filtration capability to 20 microns ensures material quality before pastillation, critical for minimizing contamination. Overall, the pastillator machine’s design accommodates varying resin viscosities (500–40,000 mPas) and pressures up to 15 bar g, providing adaptability within complex resin production environments.

Enhanced Process Reliability and User-Centric Operation

Performance-wise, the system offers rapid heat-up and discharge temperatures ranging from 30–40°C with a required cooling time under one minute, enabled by advanced steel belt cooling technology. The controlled flow mechanism through a high-pressure gear pump ensures stable pellet formation at production rates from 500 to 3500 kg/h, contributing to operational consistency. The exhaust air extraction minimizes fumes, supporting workplace safety and compliance. Additionally, automated additive powdering improves flow and handling characteristics of the final pellets. Together, these features deliver enhanced processing efficiency, maintenance convenience, and reduced operational downtime for industrial users.

Use Scenarios

Phenolic Resin Pastillation in Cable Insulation Manufacturing

Within cable insulation production, precise pelletization of phenolic resins is essential for consistent adhesive application layers. The pastillator machine provides uniform pastilles with controlled size and weight, compatible with continuous extrusion processes. Its ability to regulate high viscosity resin flow and maintain strict temperature profiles through shell heating and dual water cooling zones ensures compliance with stringent quality standards. Integrated exhaust air extraction supports environmental controls in manufacturing plants. This system effectively interfaces with cable production lines, improving throughput and ensuring stable downstream dosing and curing operations.

Epoxy Resin Solidification for Electronics Component Fabrication

In electronics manufacturing, epoxy resin pastillation requires stringent particle uniformity and contaminant-free processing. The pastillator system’s filtration precision and heated drum facilitate the formation of homogeneous pellets essential for reliable electronic encapsulation. Its rapid cooling via steel belt cooling technology reduces cycle times while maintaining thermal stability critical to electronic-grade resins. The pastillator machine supports integration into automated processing lines, enhancing operational efficiency and material traceability. This solution ensures improved resin handling and dosing accuracy necessary for high-performance electronic component fabrication.

FAQ

What types of resins can be processed with Consol’s resin solidification system?

Consol’s resin solidification line handles various materials, including hydrocarbon, phenolic, epoxy, ink, gum resins, and rosin. This flexibility ensures compatibility with multiple industrial applications requiring precise pelletizing using a pastillator machine.

Can the resin solidification system be customized for specific production needs?

Yes, Consol offers adjustable features such as pastille size, cooling rates, and additive dosing through the integrated powdering system. These customizations optimize pellet quality and support diverse production scales with the Steel Belt Granulator line.

What installation and maintenance support does Consol provide for its granulator machines?

Consol coordinates installation near client facilities worldwide and offers full after-sales service. The system includes a flushing circuit for cleaning, enhancing machine uptime and reliability critical for industrial granulator machine operations.

How does the resin solidification process control fumes and fiber generation?

An exhaust air extraction system and a specially designed hood with a collection channel reduce fumes, while shell heating minimizes fiber release during pelletizing. These features ensure compliant and safe operation in resin pastillation environments.

OUR CAPABILITY

CONSOL is an international enterprise focusing on steel belt and steel belt driving system.

Related Products