-

-

-

BLOG&EVENT

-

ABOUT US

Contact Us

E-mail info2@consolbelts.com

Phone/WhatsApp/Wechat

+86 18820135908

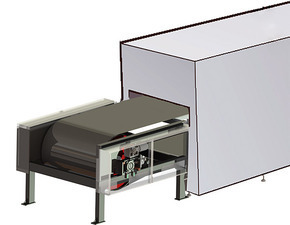

Wax granulation

Uniform size of pastilles,stable properties over time

Транспортная система

Typical Waxes

Paraffin Wax

Microwax

PE Wax

Montan Wax

AKD Wax

Bee Wax

Depilating Waxes

Flavoured Waxes

Characters

• Uniform size of pastilles

• Consistent quality

• Stable properties over time

• Free flowing product

• Low friability and good impact abrasion resistance (low visual dust generation)

• High purity

- From melt to pastilles in one operation

Breaking or grinding equipment is not required

- Semi-spherical pastilles of uniform size for good handling easy metering and minimum dust generation

- System versatility - easy changeover to different products pastille sizes and solidification capacities

- No contact between product and cooling media

- Short contact between product and ambient air

(blanketing with inert gases is possible)

- Easy service, good access, simple and light spare parts

OUR CAPABILITY

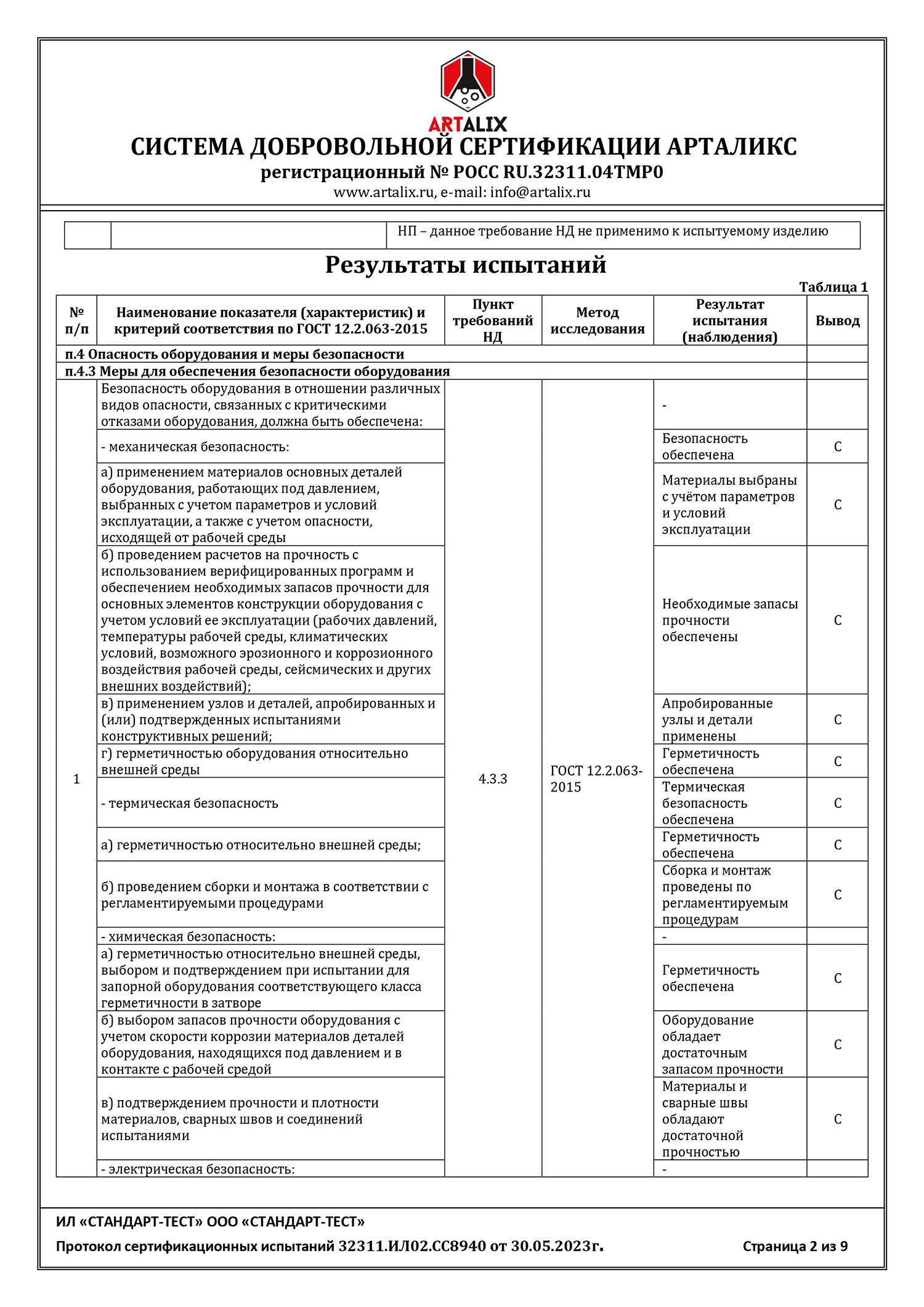

CONSOL is an international enterprise focusing on steel belt and steel belt driving system.

Related Products

19, No.63 jieyuan road, Shawan town, Panyu dist, Guangzhou, China

Request Quote

We will contact you within one working day. Please pay attention to your email.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.