Contact Us

E-mail info2@consolbelts.com

Phone/WhatsApp/Wechat

+86 18820135908

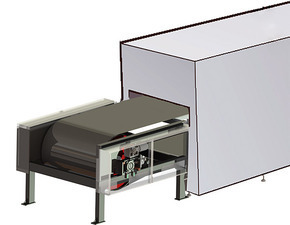

Steel belt cooler

Steel belt cooler pastillator is suitable for granlation and flake of resin, sulfur, wax, chocolate, chemicals,foods.Good corrosion resistance, long service life, suitable for a variety of materials.

Транспортная система

Steel belt cooler pastillator technology

Under the new situation,the advantages of the steel belt cooler pastillator have been continuously explored and become an indispensable production equipment in various industrial fields, a large number of companies who need powder and solidification are greatly used the steel belt cooler as core production line.

· In the field of agricultural production, the requirements of appearance, physical properties, composition and release effect of fertilizers have changed greatly. Fertilizer sow machine requires good particle uniformity and dispersion, so steel belt cooler for granulation is the best choice.Fertilizer produced by steel belt pastillator is well packaging and transporting, low pollution, good formability. Ingredients require more and balanced, due to the ground fertilization.

· In the field of chemical production, due to the requirements of the environment and production process, especially the addition form of catalyst, there are requirements on the shape of materials for granulation.Chemical granulation produced by steel belt cooler is more easy to calculate,less powder, the dust can greatly reduce inside the packaging.The size of granulation can be adjusted according to different applications.

· In the field of dye production, the physical properties of dyes can be effectively changed by agglomeration granulation, while dust pollution can be prevented, the solubility and the operating environment can be improved, and the operating environment can be improved.The great heat-conducting capabilities of steel belt cooler pastillator can maximize the output of powder coating.

· In the field of pharmaceutical production, a layer of film is formed on the surface of the drug through coating and granulation technology, because the film can improve the appearance, conceal the bad smell, facilitate the patient to take, control the drug release, improve the drug release curve, moisture proof, avoid light, and isolate the air to increase the stability of the drug.

Such a wide range of applications of steel belt pastillator is mainly due to the irreplaceable advantages of itself.

1. High efficiency and environmental protection; materials and cooling water are completely out of contact to avoid mutual pollution;Cooling water can be recycled;Very few volatile gases and dust production.

2. Simplify the process.For example, steel belt cooler can achieve the material from the molten state to the final curing.

3. The product is convenient for storage, transportation, mixing, packaging and subsequent processing.

4. Low energy consumption, less investment, easy to operate.

5. Good corrosion resistance, long service life, suitable for a variety of materials.

Main types of steel belt cooler pastillator

Features of single steel belt granulation/flakes cooler

The whole machine structure is block overlap type, with arbitrary length combination;The types of the former are internal rotation, external rotation and reciprocating.The speed of the former and the speed of the steel belt are stepless.The control system is stable and reliable with superior performance.

Application direction/performance characteristics of single steel belt cooler: the product shape is pellet, strip and flake;The production capacity of single belt cooler is 300-30000 tons/year. Typical materials are petroleum resin, phenolic resin, poly Amide resin, rosin resin, terpene;Paraffin, sulfur, asphalt, maleic anhydride, trimellitic anhydride, alkali sulfide, oleic acid, hexapalamide resin, fatty acids;Plasticizer (dispersant), aluminum sulfate, calcium chloride;Anti-aging agent RD, anti-aging agent 4010Na;M-phenylenediamine, catechol, stearate, sodium thiohydride;Polyethylene wax, MOCA, p-nitrochlorobenzene;EVA hot melt adhesive, bisphenol A, fatty alcohol, etc.

Efficient Cooling Mechanism for Optimal Solidification

The CONSOL Steel Belt Cooler employs a continuous stainless steel belt system that facilitates the efficient transfer of heat, rapidly cooling molten substances into solid forms. This technology is essential for processes involving pastillator machines, granulator machines, and industrial granulators, ensuring high throughput and consistent product quality.

Versatile Applications Across Multiple Industries

Designed to handle a wide range of materials, including resins, waxes, sulfur, and food products like chocolate, the CONSOL Steel Belt Cooler is a preferred choice among granulator manufacturers. Its adaptability makes it suitable for various sectors, ensuring reliable performance and product consistency.

Robust Construction for Long-Term Reliability

Constructed with high-grade stainless steel and corrosion-resistant components, the CONSOL Steel Belt Cooler is built to withstand the rigors of continuous industrial operation. This durability ensures minimal maintenance and long service life, making it a cost-effective solution for granulator machine operations.

Efficient Design for Enhanced Productivity

The system's design includes features like adjustable belt speeds and precise temperature controls, allowing for customization based on specific material requirements. Such flexibility enhances the efficiency of pastillator and granulator processes, leading to increased productivity and reduced operational costs.

User-Friendly Interface for Simplified Operation

Equipped with an intuitive control panel, the CONSOL Steel Belt Cooler allows operators to monitor and adjust settings with ease. This user-friendly interface ensures smooth operation, reducing the learning curve and enhancing overall process efficiency in industrial granulator applications.

Product Advantages

- High Efficiency and Output: Delivers rapid cooling and solidification, essential for high-volume granulator machine operations.

- Versatile Material Compatibility: Capable of processing a diverse range of substances, making it ideal for various pastillator applications.

- Durable and Reliable: Built with robust materials to ensure longevity and consistent performance in demanding industrial environments.

- Advanced Cooling Mechanism: Features a sophisticated cooling system that enhances the quality and uniformity of the final product, crucial for granulator manufacturers.

- Easy Integration and Operation: Designed for seamless incorporation into existing systems with a user-friendly interface, facilitating efficient industrial granulator processes.

About CONSOL

Industry Positioning

CONSOL is a leading international enterprise specializing in steel belts and steel belt driving systems, providing reliable solutions to customers worldwide.

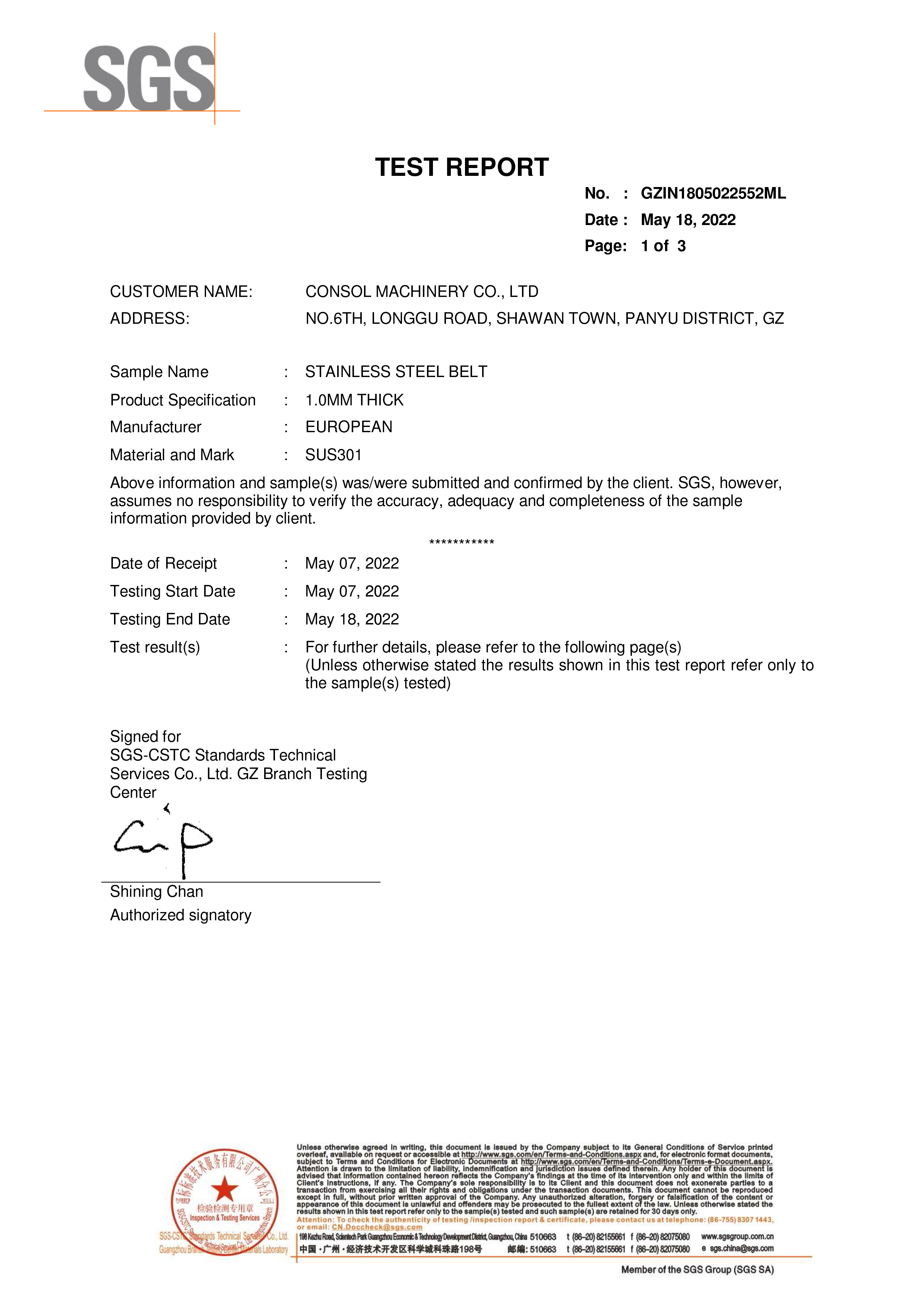

Core Manufacturing Capabilities and Quality Assurance

Product Range: We offer a diverse array of steel belts, including carbon steel belts, stainless steel belts, perforated steel belts, super mirror steel belts, precision steel belts, and martensitic stainless steel belts.

Application Areas: Our products are utilized across various industries such as oil & gas, chemical, food, precision machinery, film casting, woodworking, and composite industries.

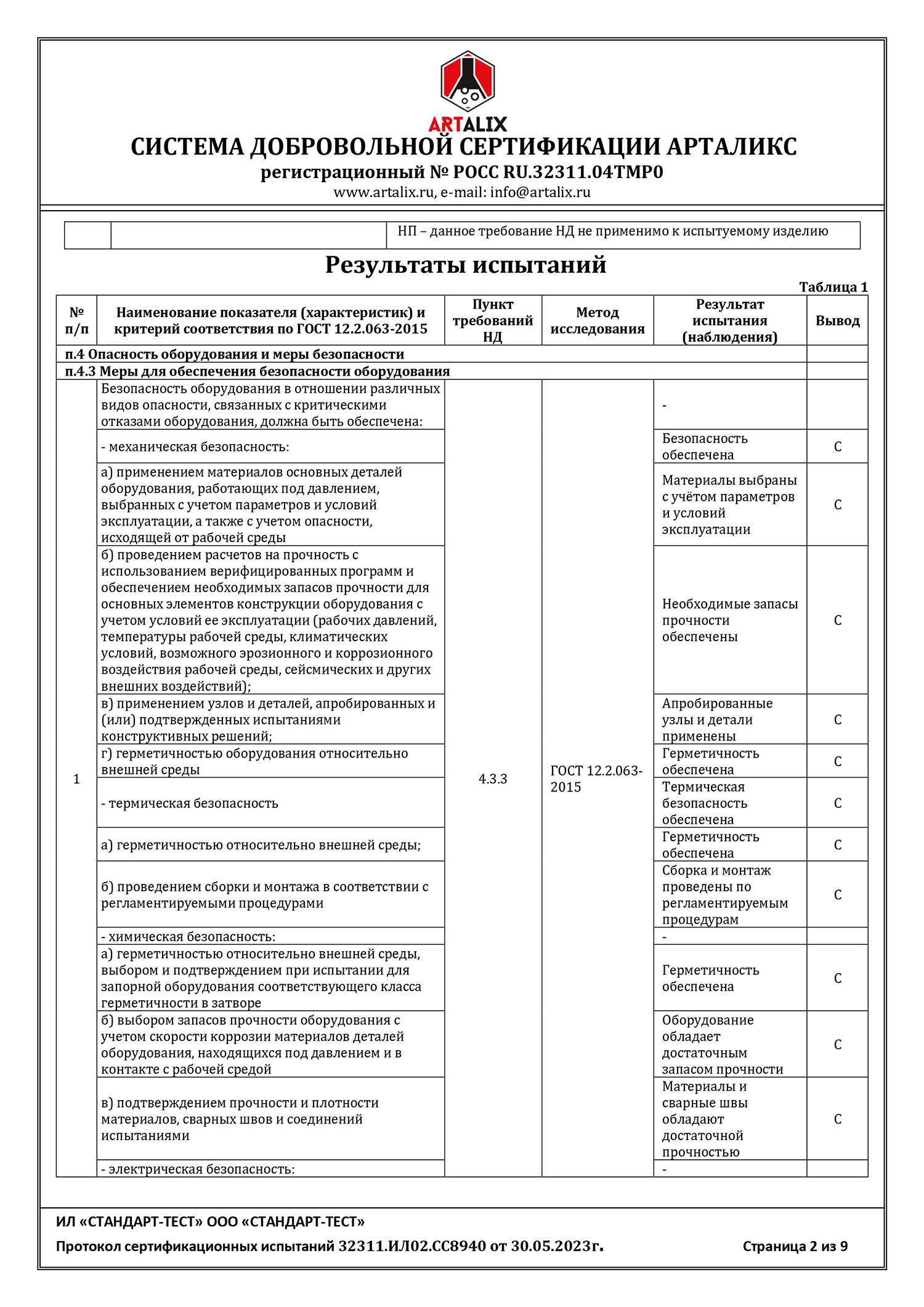

Quality Commitment: We adhere to stringent quality standards to ensure our products meet the highest industry requirements.

Production Strength

Located in Guangzhou, the heart of the Pearl River Delta, CONSOL has established a robust manufacturing base, enabling us to serve clients efficiently across the globe.

Sustainability Measures

Our steel belts are designed for durability and recyclability, contributing to sustainable industrial practices.

Customer Collaboration Process

We have built a comprehensive sales and after-sales service system, coordinating installation services near our clients' facilities to ensure optimal service quality.

Global Service Capability

Over the past decade, CONSOL has exported products to more than 30 countries, including the USA, Russia, Canada, Korea, South Africa, Iran, Turkey, Ukraine, Saudi Arabia, Spain, Holland, Brazil, Malaysia, Thailand, India, Pakistan, the Philippines, Indonesia, and Vietnam.

FAQ

What materials can the CONSOL Steel Belt Cooler process effectively?

The CONSOL Steel Belt Cooler is designed for granulation and pastillation of diverse materials, including resins, sulfur, wax, chocolate, chemicals, and food products. Its corrosion-resistant stainless steel belt ensures durability and consistent performance across these varied applications, supporting efficient cooling and solidification.

Can the cooling speed and product shape be customized in this flaker machine?

Yes, the CONSOL Steel Belt Cooler features stepless adjustable belt speeds and precise temperature controls, allowing operators to customize cooling rates. It also supports multiple product shapes such as pellets, strips, and flakes, accommodating specific production requirements of the steel belt flaker equipment.

How does CONSOL support installation and integration of the steel belt cooling system?

CONSOL provides comprehensive assistance, including delivery, installation, and after-sales services worldwide. The system's design allows easy integration into existing production lines, supported by user-friendly controls and reliable operational stability for effective steel belt cooling in industrial environments.

What maintenance considerations apply to the double belt cooler system?

Regular maintenance focuses on belt cleaning, tension adjustment, and temperature controller calibration to maintain optimal performance. The durable stainless steel construction of the double belt cooler minimizes corrosion risks, reducing downtime and ensuring long-term reliability in continuous industrial operation.

OUR CAPABILITY

CONSOL is an international enterprise focusing on steel belt and steel belt driving system.

Related Products