Contact Us

E-mail info2@consolbelts.com

Phone/WhatsApp/Wechat

+86 18820135908

Sulphur bentonite granulation

Sulphur bentonite granulation is an innovative process designed to produce high-quality sulphur fertilizers

Транспортная система

Sulphur bentonite granulation is an innovative process designed to produce high-quality sulphur fertilizers. This specialized technique combines sulphur with bentonite, a natural clay mineral, resulting in granules that provide efficient and targeted nutrient release in the soil.

The sulphur bentite granulation process begins with the mixing of liquid sulphur and bentite clay. The mixture is transformed into small granules with help of advanced granulation equipment. These granules act as carriers for sulphur, providing a controlled release of this essential nutrient time.

One of the standout features of sulphur bentonite granulation is its ability to enhance soil fertility and crop yield. The sulphur present in the granules contributes to the growth and development of plants, promoting chlorophyll formation and enzyme activation Additionally, the inclusion of bentonite clay provides excellent binding and absorption properties, ensuring efficient nutrient uptake by plants.

The sulphur bentonite granules find extensive use in the agriculture industry, particularly in the cultivation of crops such as cereals, fruits, vegetables, and oilseeds. The granules are easily applied to the soil, either in their pure form or as a blend with otherizers. They release sulphur gradually, allowing for sustained nutrient availability throughout the crop growth cycle.

One of the unique selling points of sulphur bentonite granules is their ease of handling and application. These granules are dust-free and non-caking, making them convenient to transport and spread evenly in the field., the granulation process ensures consistent granule size and quality, facilitating precise nutrient distribution and reducing wastage.

By utilizing sulphur bentonite granulation, farmers can achieve improved crop yields, enhanced nutrient efficiency, and reduced environmental impact. The controlled release of sulphur helps to prevent nutrient leaching and enables plants to access sulphur when they need it most, resulting in healthier and more productive crops.

In summary, sulphur bentonite granulation is a cutting-edge process that allows for the production of high-quality sulphur fertilizers. With its unique combination of sulphur and bentonite clay, this technique offers precise nutrient release, improved soil fertility, and increased crop yields. Discover the benefits of sulphur bentonite granulation and optimize your agricultural operations for sustainable and efficient nutrient management.

Precision Granulation for Sulphur-Bentonite Fertilizers

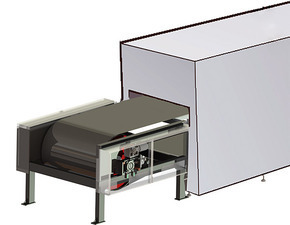

The CONSOL Sulphur Bentonite Granulation system is a highly specialized pastillator machine engineered for the transformation of molten sulphur mixed with bentonite clay into uniform pastilles. This granulator machine guarantees even distribution and precise control, resulting in high-quality fertilizers essential for modern agricultural applications.

Advanced Belt Cooling System

Utilizing a water-cooled stainless steel conveyor, this industrial granulator ensures that the pastilles are rapidly solidified without contamination. This method is widely adopted by leading granulator manufacturers seeking consistent and efficient granulation under controlled conditions.

Reliable and Versatile for Multi-Industry Use

Beyond sulphur-bentonite, the CONSOL pastillator can handle other granulation materials like urea, sulphur, and specialty chemical fertilizers. This versatility makes it a trusted granulator machine among manufacturers requiring adaptable solutions for various production lines.

Ease of Maintenance and Operation

The user-friendly interface and modular structure reduce downtime and simplify operation. Whether operated as a standalone pastillator machine or integrated into a full industrial granulator system, CONSOL’s design focuses on performance and longevity — key to industrial-scale reliability.

Product Advantages

- Uniform Granule Size: Ensures precise granulation through an advanced pastillator machine, minimizing fines and dust during processing.

- High Productivity: The automated cooling and conveying system significantly boosts the capacity of this industrial granulator, ideal for large-scale output.

- Energy Efficient Design: Water recirculation and low-power components enhance the efficiency of this granulator machine.

- Proven Technology: Trusted by international granulator manufacturers, CONSOL's systems are built on over a decade of expertise in pastillator and granulator machine design.

- Scalable and Customizable: Whether you're a small or large-scale industrial granulator user, this system adapts to your throughput needs seamlessly.

About CONSOL

Industry Positioning

CONSOL is a leading international enterprise specializing in steel belts and steel belt driving systems, providing reliable solutions to customers worldwide.

Core Manufacturing Capabilities and Quality Assurance

Product Range: We offer a diverse array of steel belts, including carbon steel belts, stainless steel belts, perforated steel belts, super mirror steel belts, precision steel belts, and martensitic stainless steel belts.

Application Areas: Our products are utilized across various industries such as oil & gas, chemical, food, precision machinery, film casting, woodworking, and composite industries.

Quality Commitment: We adhere to stringent quality standards to ensure our products meet the highest industry requirements.

Production Strength

Located in Guangzhou, the heart of the Pearl River Delta, CONSOL has established a robust manufacturing base, enabling us to serve clients efficiently across the globe.

Sustainability Measures

Our steel belts are designed for durability and recyclability, contributing to sustainable industrial practices.

Customer Collaboration Process

We have built a comprehensive sales and after-sales service system, coordinating installation services near our clients' facilities to ensure optimal service quality.

Global Service Capability

Over the past decade, CONSOL has exported products to more than 30 countries, including the USA, Russia, Canada, Korea, South Africa, Iran, Turkey, Ukraine, Saudi Arabia, Spain, Holland, Brazil, Malaysia, Thailand, India, Pakistan, the Philippines, Indonesia, and Vietnam.

FAQ

Who are we?

CONSOL is an international enterprise focusing on steel belts and steel belt driving systems, committed to providing reliable solutions to customers worldwide.

How can we guarantee quality?

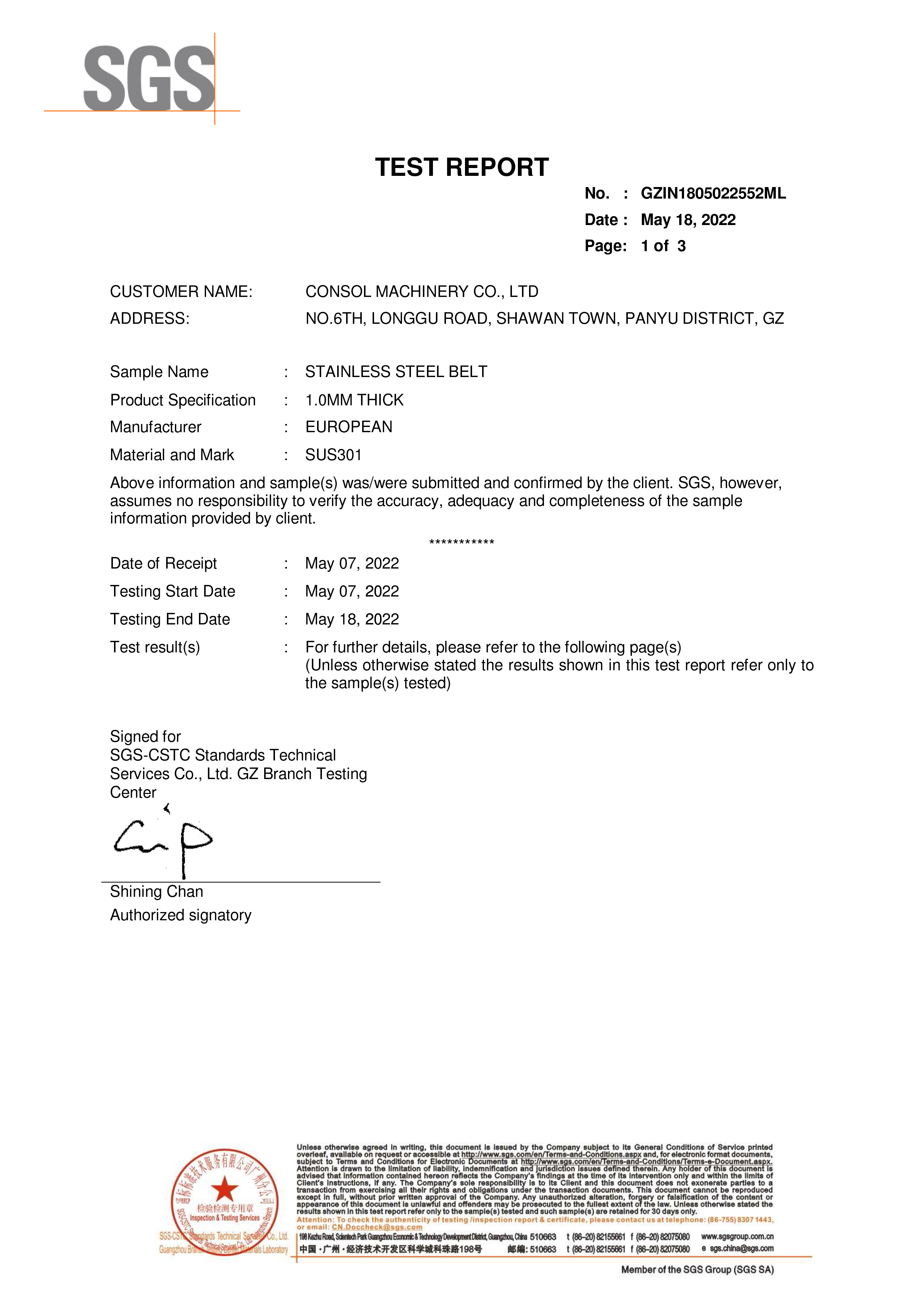

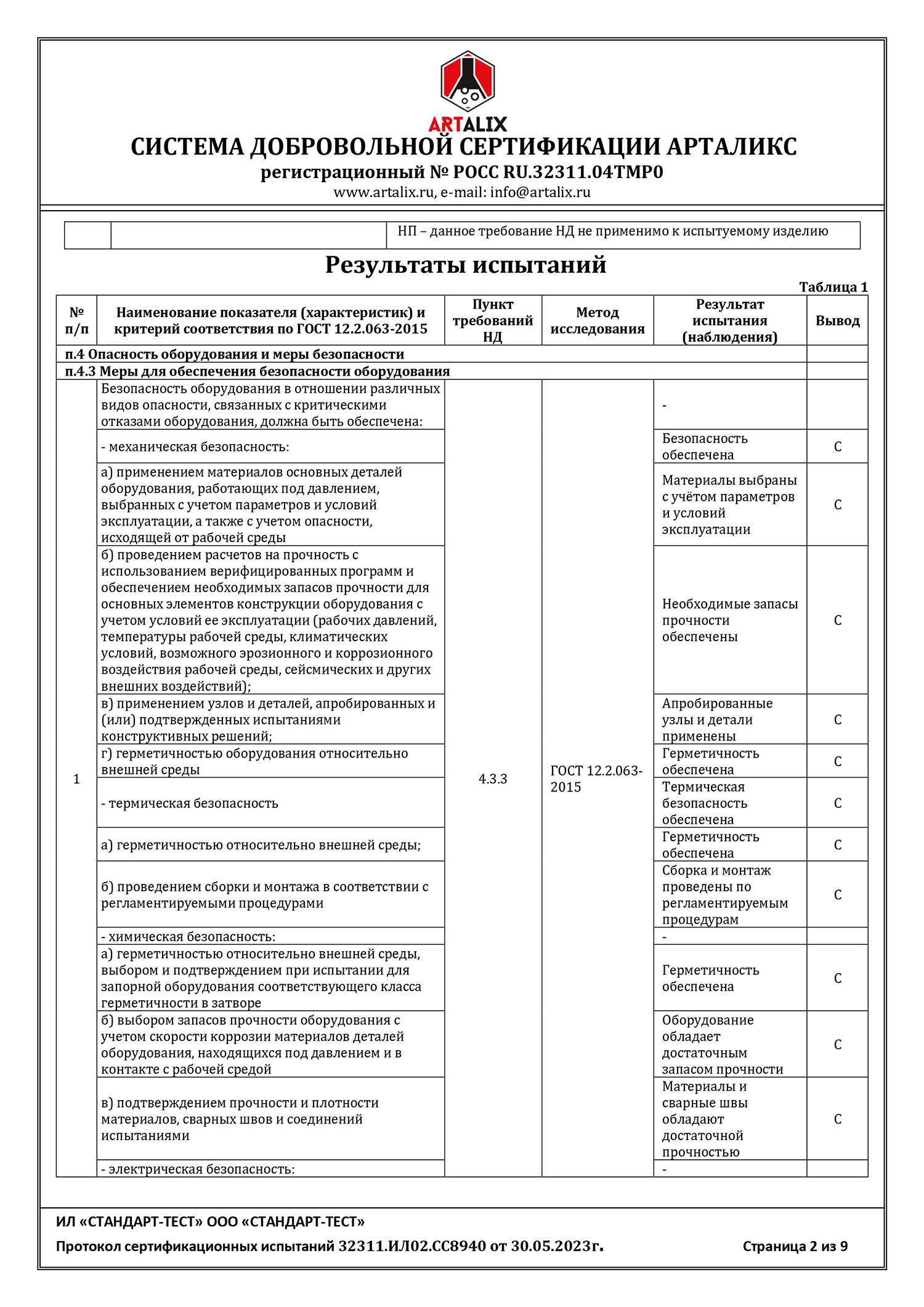

We adhere to strict quality control processes and hold certifications such as SGS, CE, and ISO 9001 to ensure our products meet international standards.

What can you buy from us?

Our product offerings include various types of steel belts and conveyor systems suitable for multiple industrial applications.

Why should you buy from us and not from other suppliers?

With a decade of experience exporting to over 30 countries and a commitment to quality and customer service, CONSOL stands out as a reliable partner for your industrial needs.

What services can we provide?

We offer comprehensive services, including after-sales support, seamless welding technology, edge shaping, conveyor system rebuilding, and V-rope sticking, ensuring our clients receive end-to-end solutions.

Enhance your production efficiency with the CONSOL Sulphur Bentonite Granulation system. Contact us today to learn how our advanced granulation solutions can meet your industrial needs.

OUR CAPABILITY

CONSOL is an international enterprise focusing on steel belt and steel belt driving system.

Related Products