Contact Us

E-mail info2@consolbelts.com

Phone/WhatsApp/Wechat

+86 18820135908

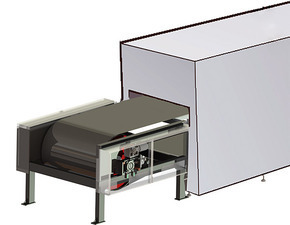

Carbon Steel Belt CS1300

Carbon steel belt refers to CS1300 tempered carbon steel, which has a smooth and hard surface, and is widely used in cookie baking tunnel ovens.

Стальная лента

Unmatched Efficiency and Thermal Conductivity

The Carbon Steel Belt CS1300 from Guangzhou Consol Machinery Equipment Co., Ltd is engineered to redefine efficiency in industrial baking applications. This conveyer belt is crafted from tempered carbon steel, ensuring a smooth and hard surface that facilitates even heat distribution. This feature is crucial for achieving consistent baking results, making it an ideal choice for manufacturers seeking reliable conveyor belt solutions. The Steel belt conveyor design enhances thermal conductivity, allowing the belt to withstand temperatures up to 350°C without compromising performance. This ensures that your products are baked to perfection every time, reducing the number of defective outputs and maximizing productivity.

Built for Durability and Precision

Durability and precision are at the core of the Carbon Steel Belt CS1300. Unlike traditional mesh belts, this conveyor belt system offers superior wear resistance and static strength, making it a long-lasting investment for any industrial setting. The belt's robust construction minimizes maintenance needs, allowing for seamless integration into existing conveyor belt systems. Its compatibility with various baking processes, from cookies to bread, ensures that manufacturers can meet diverse production demands without frequent adjustments. As a leading choice among conveyor belt manufacturers, Consol's steel belt provides a stable and reliable platform for high-quality production.

Scalable Design for Future Growth

The Carbon Steel Belt CS1300 is not just a solution for today but a scalable asset for future growth. Its adaptability to new product developments and trial productions makes it a strategic choice for manufacturers looking to expand their offerings. The belt's easy maintenance and repairability further enhance its long-term value, ensuring that it remains a vital component of your conveyor belt system for years to come. By choosing Consol's Steel belt conveyor, manufacturers can stay ahead of market trends and capitalize on new opportunities with confidence. This product exemplifies the innovation and reliability that conveyor belt manufacturers strive to deliver, making it a cornerstone of efficient industrial operations.

Use carbon steelbeltas oven conveyor belt for many years, the traditional oven conveyor belt uses mesh belt,which hasscharacters ofcheap, simple maintenance etc.. As people has increased the demand for biscuit&cookies.,and the type of products also increase,wire meshbelt can no longer meet the needs of diversified production, so more and more factories begin to consider theoven steel belt..

The steel belt has many advantages over the mesh belt.

Better compatibility.

The surface of thecarbon ovensteelbeltis smooth andflat,, without potholes and holes.,Ensuringthe productwill beheated evenly, resulting in better color and taste.Due to the fragile nature of cookies, only steel belt can transport it through tunnel oven.. The compatibility of steel belt makes more and more manufacturers no longer choose mesh belt.Biscuit factoryin different regions can choose to producehardbiscuit s orsoftcookies according tothelocaldemand,, and the steel beltcan be compatible with any type ofbiscuits&cookieproduction.sBetter physical properties.

The

steel belt has excellent thermal conductivity and heat resistance, the carbon oven steel belt cancarbon ovenworksmoothly attemperature up to350°C, no shaking makes the product have a better baking environment, greatly reducing the number of defective finished products.Most steel belts are repairable. If the steel belts are damaged or cracked for some reason, they can be restored to working condition by technical means. Generally, as long as the oven equipment is reasonable.Thesteel belt is not easy to damage, so the general steel belt service life is very long, some can evencarbon ovenreachmore than ten years. more than ten years.

Better maintenance.

steel belt has excellent thermal conductivity and heat resistance, the carbon oven steel belt cancarbon ovenSteel belt is easy to install and can be welded or riveted. Because its strength is better than the general conveyor belt, so due to wear, fatigue and other problems are greatly reduced, onlyneeda small amount of maintenance at ordinary times. In addition, the smooth surface is not easy tostain material and oil,, do not need to spend time to cleanand can havethe highest level of hygiene.

Future trends.

The advantages of steel belt make more and more manufacturers choose steel belt as its core conveyor belt. Steel belt can adapt to the manufacturers in the production research and development of new products and can immediately carry out trial production, which allows manufacturers to seize the most priority opportunities for new product sales, to seize the best demand market.

Carbon steel belt characteristics.

Made of hardening or tempering hardened carbon steel, Consol belt has the following characteristics:

●Good flatness.

●Great static strength.

●Excellent fatigue and wear resistance.

●Outstanding thermal conductivity.

●Hard and smooth, easy to clean.

●Easy to maintain.

●Better than wire mesh conveyor belt.

●Corrosion resistance,

●Have certain recycling value.

Dynamic strength.

Scope of supply.

Weldability.

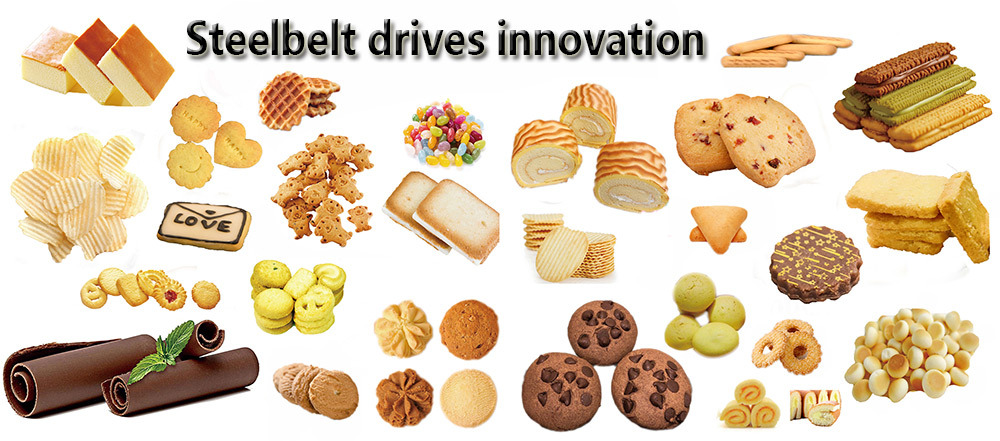

Application scope.

Carbon steel belt is suitable for cookies, Swiss roll, cake, white lover, chocolate, nuts cake, bread, Italian crispy cakes, muffins, brownie, puff, crackers, oaten cake, ginger bread, cereals, Christmas gingerbread, marin sugar, dragon card, French cake, pizza, sponge cake and other food production processes.

See carbon steel belt complete parameter.

About CONSOL

Industry Positioning

CONSOL is a leading international enterprise specializing in steel belts and steel belt driving systems, providing reliable solutions to customers worldwide.

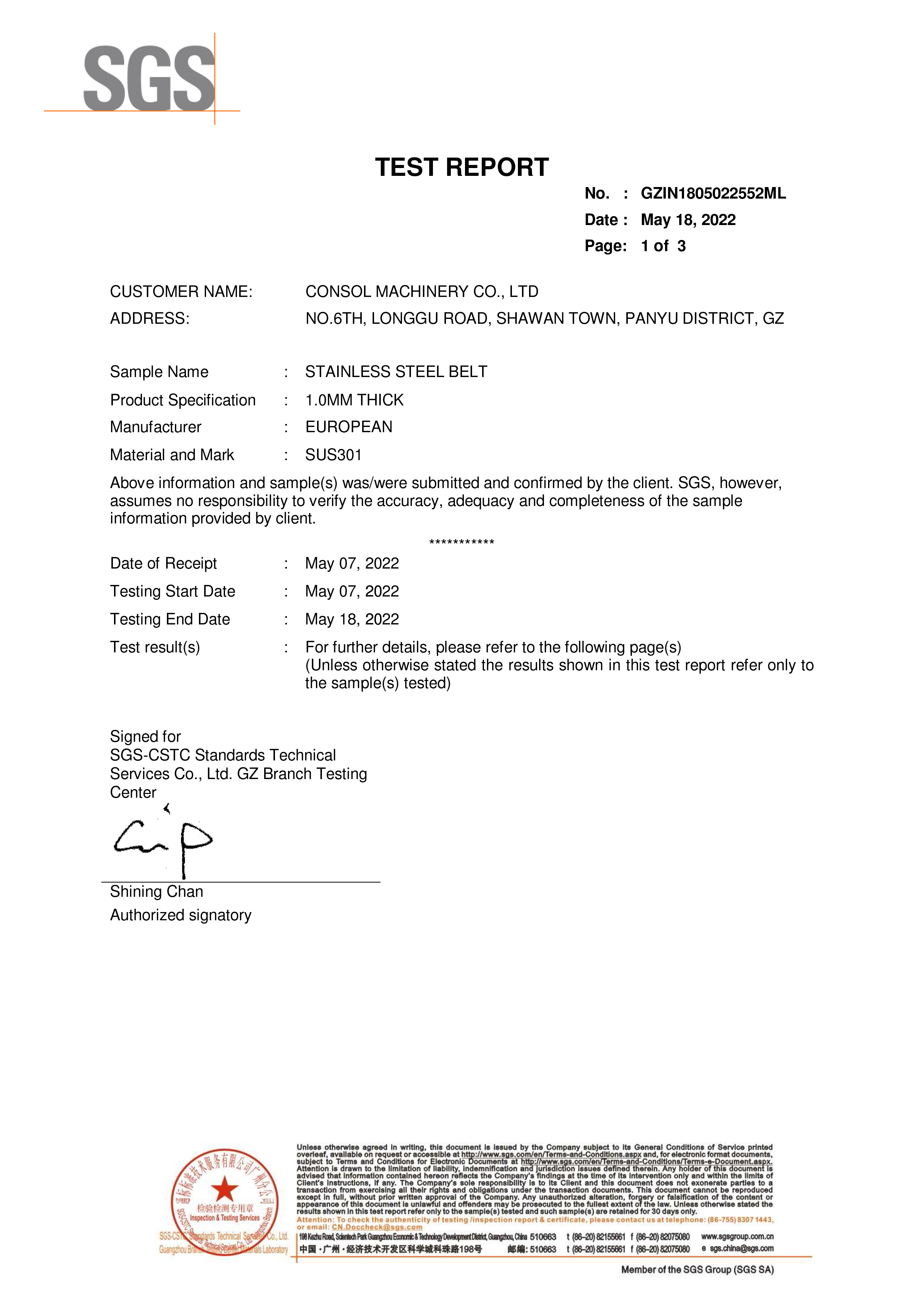

Core Manufacturing Capabilities and Quality Assurance

Product Range: We offer a diverse array of steel belts, including carbon steel belts, stainless steel belts, perforated steel belts, super mirror steel belts, precision steel belts, and martensitic stainless steel belts.

Application Areas: Our products are utilized across various industries such as oil & gas, chemical, food, precision machinery, film casting, woodworking, and composite industries.

Quality Commitment: We adhere to stringent quality standards to ensure our products meet the highest industry requirements.

Production Strength

Located in Guangzhou, the heart of the Pearl River Delta, CONSOL has established a robust manufacturing base, enabling us to serve clients efficiently across the globe.

Sustainability Measures

Our steel belts are designed for durability and recyclability, contributing to sustainable industrial practices.

Customer Collaboration Process

We have built a comprehensive sales and after-sales service system, coordinating installation services near our clients' facilities to ensure optimal service quality.

Global Service Capability

Over the past decade, CONSOL has exported products to more than 30 countries, including the USA, Russia, Canada, Korea, South Africa, Iran, Turkey, Ukraine, Saudi Arabia, Spain, Holland, Brazil, Malaysia, Thailand, India, Pakistan, the Philippines, Indonesia, and Vietnam.

FAQ

What materials are used in the Carbon Steel Belt CS1300?

The Carbon steel belt CS1300 is made from tempered carbon steel with a smooth, hard surface designed for even heat distribution. This material ensures high thermal conductivity, durability, and corrosion resistance, making it ideal for high-temperature industrial baking and conveyor applications.

Can the CS1300 belt be customized to fit existing conveyor systems?

Yes, the CS1300 belt is engineered for easy integration and adaptability, allowing retrofit and upgrade of current conveyor lines. Its durable, wear-resistant construction supports various high-temperature baking processes with minimal downtime during installation or system updates.

How should maintenance and repairs be handled for the baking oven conveyor belt?

The baking oven conveyor belt CS1300 is repairable, extending its service life through professional technical restoration. Routine maintenance focuses on cleaning the smooth surface and inspecting wear to reduce downtime and preserve thermal performance in high-temperature baking lines.

What logistics and support services does CONSOL provide for international customers?

CONSOL offers a comprehensive customer service network, including coordinated on-site installation, alignment checks, and after-sales support. Products, including metal conveyor belts, are shipped globally with technical assistance available to ensure reliable operation in diverse industrial environments.

OUR CAPABILITY

CONSOL is an international enterprise focusing on steel belt and steel belt driving system.

Category:

Keyword:

Related Products