Contact Us

E-mail info2@consolbelts.com

Phone/WhatsApp/Wechat

+86 18820135908

Carbon Steelbelt-Biscuits

Carbon steel belt /oven band for biscuits is more friendly for baking hard biscuit,better taste because of uniform heating...

Стальная лента

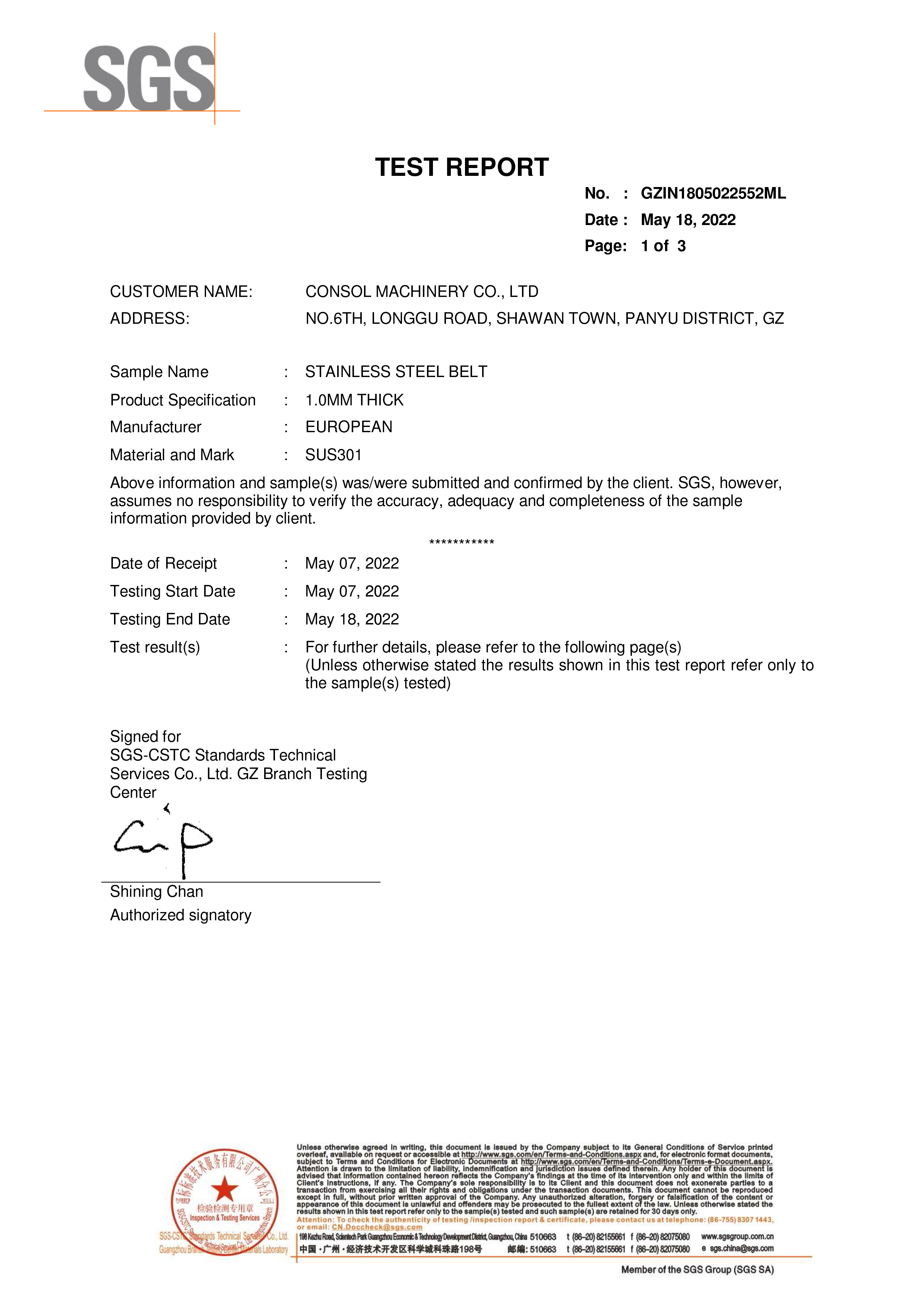

CS1300 Carbon Steelbelt is tempered carbon steel,which has follow steel belt characteristics:

●Good static strength

●Outstanding fatigue resistance

●Great thermal conductivity

●Excellent fatigue and wear resistance

●Easy to maintain and repair

Carbon Steelbelt-Biscuits CS1300 has the hard and smooth surface,which has a layer of oxide on it.This steel belt is widely used in many fields with low causticity environment.Because of the outstanding thermal conductivity,CS1300 is very suitable for baking process,it also performs well in heating and drying liquid,paste and particle.

General corrosion

Although there is a layer of oxide on surface,but Carbon Steelbelt-Biscuits CS1300 is still corroded easily in the water solution,especially acid solution.The corrosion of CS1300 is accelerated by increasing temperature, velocity of flow,acidity, and salt content in solution Chromate (CrO4-2) and nitrate(NO3-) will inhibit corrosion in neutral solution.

Pitting and crevice corrosion

The carbon steel may be sensitive to pitting and cracking in solutions of a relative low oxide content.

Hydrogen embrittlement

Consol CS1300 steel belt is susceptible to hydrogen embrittlement , special heat treatment of the steel belt is required if the steel belt is exposed to hydrogen embrittlement envirment.

Welding

Carbon Steelbelt-Biscuits CS1300 has good welding property, a suitable fusion welding method is gas-shielded arc welding,with the TIG method as first choice.

Before welding,heat treatment should be applied evenly to ensure the mechanical property(static and dynamic) of welding joint.More information please contact CONSOL office.

Product Advantages

Structural and Design Robustness

The Carbon Steelbelt-Biscuits employs a tempered carbon steel design optimized for mechanical strength and wear resistance, forming an integral part of reliable steel belt assemblies. Its smooth, oxide-coated surface enhances resistance against abrasion and extends service life within industrial conveyors. The belt’s design supports efficient welding, specifically gas-shielded arc techniques like TIG welding, facilitating modular repair and system integration without extensive downtime. This structural adaptability allows it to fit diverse conveyor configurations and drying system setups, underscoring its role as a versatile element in conveying systems tailored for baking and food industry applications.

Enhanced Operational Performance and User Value

From a performance perspective, the steel belt delivers uniform heating essential for optimal biscuit quality, minimizing product inconsistencies associated with thermal variance. Its fatigue and wear resistance reduce the frequency of belt replacements, providing cost-effective operational continuity. Maintenance procedures are streamlined through easy repairability and compatibility with standard welding methods, which reduces labor costs and system interruptions. For engineering teams managing industrial conveyors and drying systems, the Carbon Steelbelt-Biscuits offers reliable service life and consistent process outcomes, driving efficiency and ROI in baking and food processing production lines.

Use Scenarios

Uniform Heat Distribution in Biscuit Production Lines

In food manufacturing facilities that produce hard biscuits, this steel belt functions as a core component within baking ovens and industrial conveyors. It uniformly transfers heat, mitigating hotspots that could compromise biscuit quality. The belt’s thermo-mechanical properties comply with baking oven system requirements, ensuring stable surface temperatures during prolonged use. Its integration into existing conveyor and drying systems enhances throughput by maintaining consistent product texture and taste. Operators benefit from a steel belt designed to tolerate continuous operation under moderate corrosive conditions typical of food baking environments, supporting regulatory compliance and operational efficiency.

Role in Drying and Thermal Processing Systems

Within drying systems employed in bakery processing plants, the Carbon Steelbelt-Biscuits assists in the effective drying of liquid and particulate materials. It supports continuous baking conveyor lines where thermal uniformity and mechanical endurance are critical to process control. The belt’s resistance to fatigue under repetitive thermal cycling aligns with operational protocols for drying systems, enabling reduced downtime and maintenance frequency. By fitting seamlessly into industrial conveyor belts and drying system workflows, this product sustains product integrity from raw material handling through baking and drying stages, contributing to operational excellence and consistent final product standards.

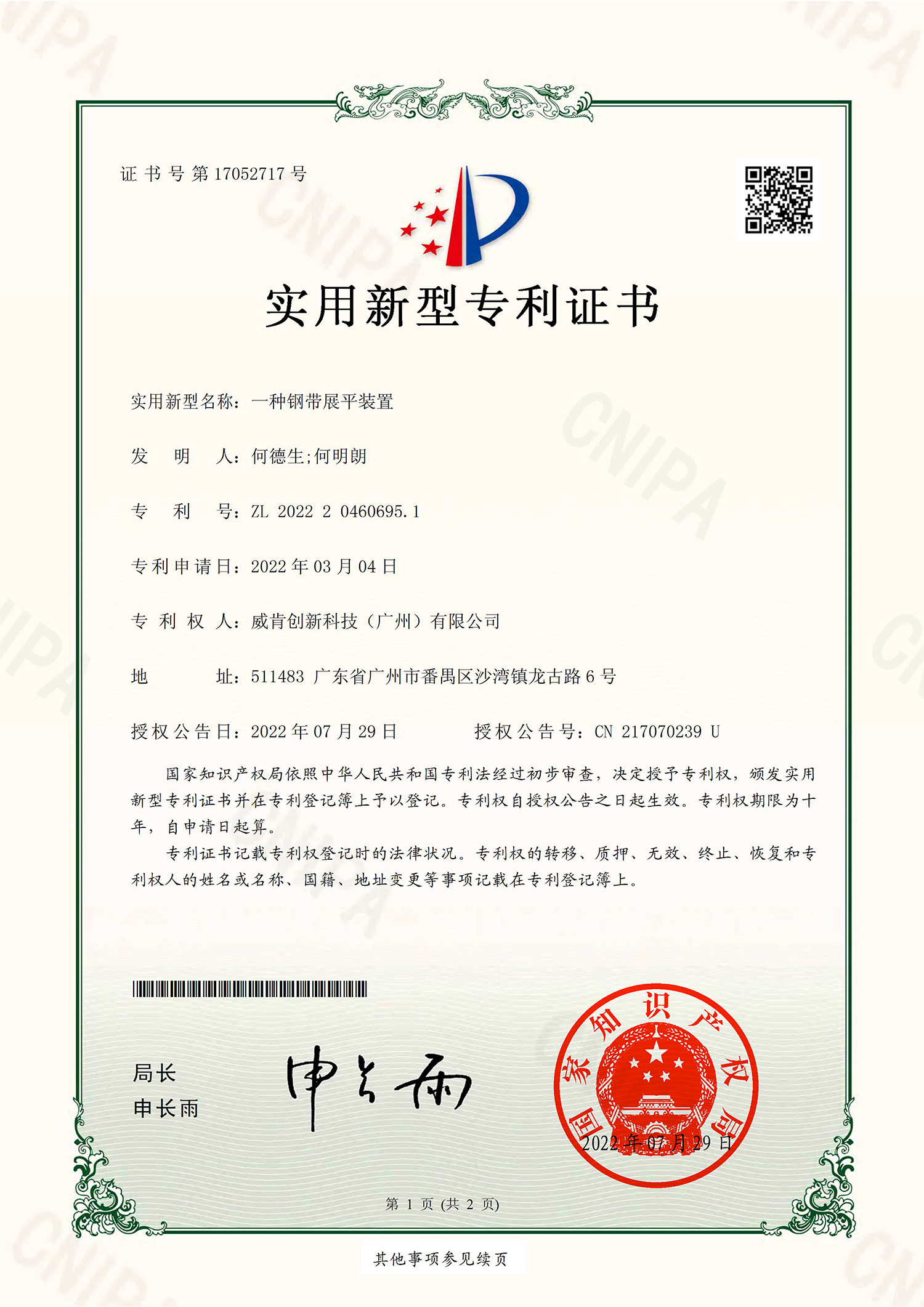

About Us

CONSOL is an international enterprise focusing on steel belt and steel belt driving systems. After years of industry accumulation and continuous development, we provide reliable steel belts and steel belt systems to customers worldwide. We emphasize steel belts as the foundation of our core technology and offer professional steel belt transmission solutions for various industries, including food, chemical, composite, rubber, and film casting industries. For Consol, quality is our only belief. Our goal is to create value for customers, pragmatically solve problems, and deliver benefits and growth.

Located in Guangzhou, the economic center of the Pearl River Delta, Consol has established branches and agent networks, building a global customer service system. No matter where you are, we ensure timely delivery, installation, and after-sales service of our steel belts. Contact us now for your custom quote!

FAQ

What materials are used in the Carbon Steelbelt-Biscuits and how do they affect performance?

The Carbon Steelbelt-Biscuits is made from tempered carbon steel, which provides high static strength and excellent thermal conductivity. This ensures uniform heating on industrial conveyor belts, essential for consistent baking quality and durability in industrial baking applications.

Can the Carbon Steelbelt-Biscuits be customized to fit specific baking oven dimensions?

Yes, Consol offers customized steel belts tailored to the specifications of your baking oven. Our expertise in conveying systems allows precise sizing and welding solutions, including TIG welding with heat treatment to ensure mechanical integrity and long service life.

What maintenance practices are recommended to prolong the lifespan of the Carbon Steelbelt-Biscuits?

Due to its sensitivity to corrosion in acidic and aqueous environments, regular inspections and cleaning are necessary. Avoid exposure to high acidity or salt conditions and perform appropriate maintenance to reduce wear and prevent damage on your industrial conveyors.

How does Consol handle logistics and installation of steel belts for international clients?

Consol has a well-established global network based in Guangzhou, enabling efficient shipment and installation services worldwide. Our technical team supports on-site installation and after-sales service to ensure seamless integration with your baking line or drying system.

OUR CAPABILITY

CONSOL is an international enterprise focusing on steel belt and steel belt driving system.

Keyword:

Related Products