Contact Us

E-mail info2@consolbelts.com

Phone/WhatsApp/Wechat

+86 18820135908

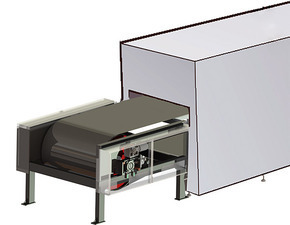

Double belt press

Composite continuous press reference of man-made board press technology

Транспортная система

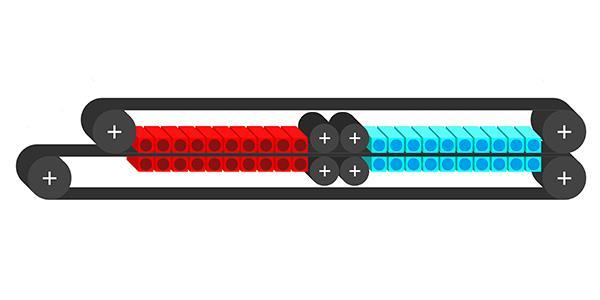

Main principles

Composite continuous double belt press reference of man-made board press technology, the main principle is to realize the steel belt under continuous operation state to pressure on the stack together film base material and the quantity of heat, and then cooling molding. Obtain new material with uniform thickness and stable quality. The thickness of the plate depends on the space between the upper and lower belts.The side seal is mainly used to determine the width of the plate.

The product is cut with required specifications by longitudinal and transverse cutters after a controlled process of polymerization, solidification and cooling.

Features

The product made by double belt press will be flat, smooth and accurate.

Temperature resistance up to 450°C.

Automatic continuous production, reduce energy consumption.

Excellent corrosion resistance and abrasion resistance to meet all requirements.

Structure

Consol designed and manufactured the stationary roller continuous double belt presser, which consists of hub, pressure roller, heating plate, lifting mechanism, hydraulic system, bearing and steel belt.

Processing

Raw materials - film laying device - table - access to front tile press (center temperature 180°C) - access to 300°C- heating area of material melting - access to thickness area - access to cooling area - access to sawing - cutting edges - scrap collection - diagonal cutting and final products.

Product usage

A variety of multilevel laminated materials

Artificial stone

Various sandwich composites

Fiber reinforced composites

Natural fiber composites

Metal composite

Brin composites

Aluminum plastic fireproof material

Other high, medium and low pressure composite materials

Consol double belt press can process continuous pressure heating and cooling processes for the production of fiberglass, carbon fiber composites, interwoven compressed fiberglass, carbon fiber pads, fabrics or thermoplastic materials.

OUR CAPABILITY

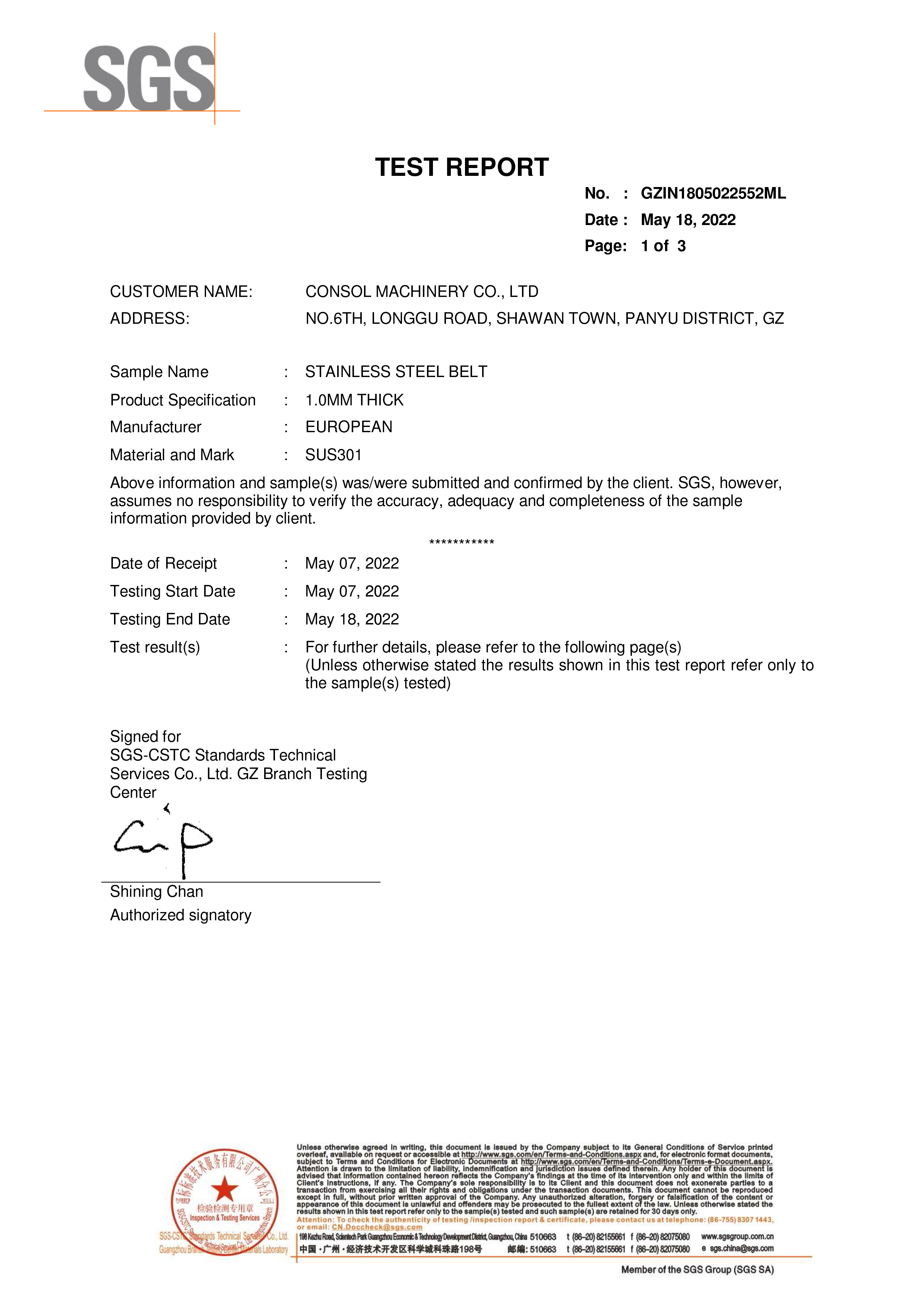

CONSOL is an international enterprise focusing on steel belt and steel belt driving system.

Keyword:

Related Products