Contact Us

E-mail info2@consolbelts.com

Phone/WhatsApp/Wechat

+86 18820135908

Mirror Steel belt

Polished mirror steel belt is produced by the polishing process of ordinary 2B steel belt.

Стальная лента

Super mirror steel belt

The application of film casting to polished steel belt has been widely used in thin film field, and its application is known as thin film flow delay. With the rapid development of liquid-crystal display, digital camera and mobile phone market, the demand for high-technology films is soaring. The films used in electronic products are mainly made of polyimide (PI), polycarbonate (PC), polypropylene (PP) or other high-tech plastic materials.

Flow skill is extended to film production,usually the technology is to make the raw materials in stainless steel with solidified into a thin film on the surface, the advantage of this process is to obtain thickness and uniform smoothness, optical performance good film. Due to the above advantages, this process is usually adopted in the production equipment.

With the increasing demand of the market for thin film surface performance, the polishing steel belt used in thin film flow equipment also needs high quality surface. We provide the corresponding level of polished steel belt according to the different requirements of the customer.

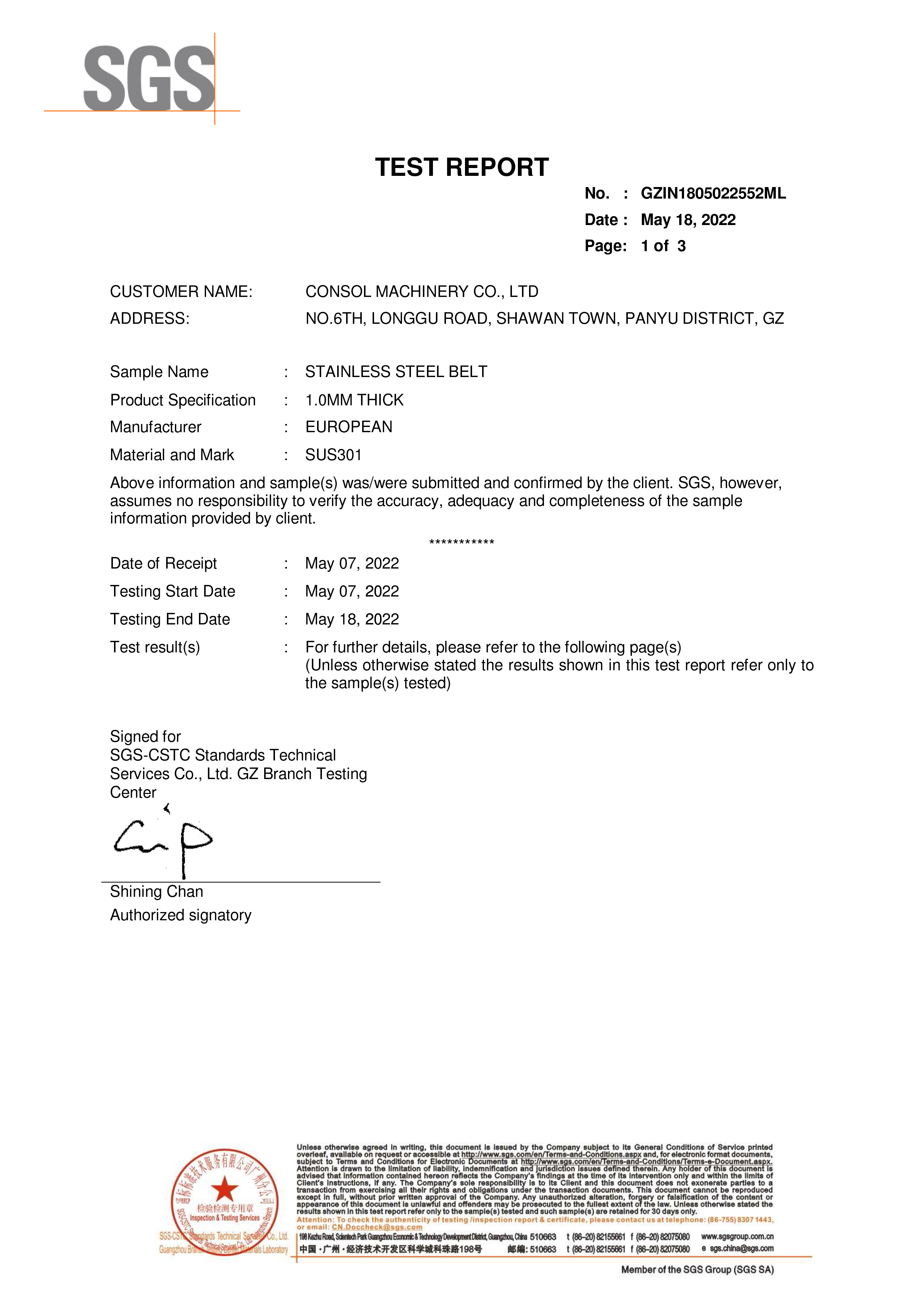

Selection of steel material

Polished steel belt is produced by the polishing process of ordinary 2B steel belt.The mechanical properties of polished steel belt and original steel belt are basically the same,unless there is a special note.

|

Parameter of polishing steel belt |

|||||

|

Polishing level |

impurity |

Surface roughness |

Deviation |

Tech |

Application |

|

JM-0 |

500μm< :not allow |

Ra≤0.02μm |

≤50μm (except for welding area) |

standard AOD |

Package |

|

JM-1 |

500μm< :not allow |

Ra≤0.02μm |

≤50μm |

Standard AOD |

high quality plant |

|

JM-2 |

100μm< :not allow |

Ra≤0.01μm |

≤50μm |

ESR |

plastic |

|

JM-3 |

70μm< :not allow |

Ra≤0.01μm |

≤40μm |

ESR |

high quality film |

|

JM-4 |

50μm< :not allow |

Ra≤0.01μm |

≤40μm |

ESR |

super high quality film |

The features of super mirror steel belt

We choose high quality raw materials, combine with advanced polishing technology,provide corresponding polishing levels for different application areas,includes a complete set of services for welding to polishing. When the high level steel belt surface is required, less impurities are existed in the steel belt,otherwise it is very difficult to obtain high quality surface quality by polishing because the impurities in the steel belt will be brought out to affect the surface in the polishing process.In order to solve this problem, we adopt ESR electroslag remelting skill to produce high quality polished steel belt. This method strictly controls the impurity content.Besides, the general steel belt is produced by Argon- Oxygen-decarburization.

Table 1 lists the typical polishing levels we can provide.We can also provide other specifications for grinding and polishing surfaces. Please contact our sales staff for details.

The steel band surface level ranges from JM-0 to JM-4. JM-0 is suitable for general surface requirements, such as packaging film, while JM-3 and JM-4 are used for high - surface requirements such as LCD with polarizing film.

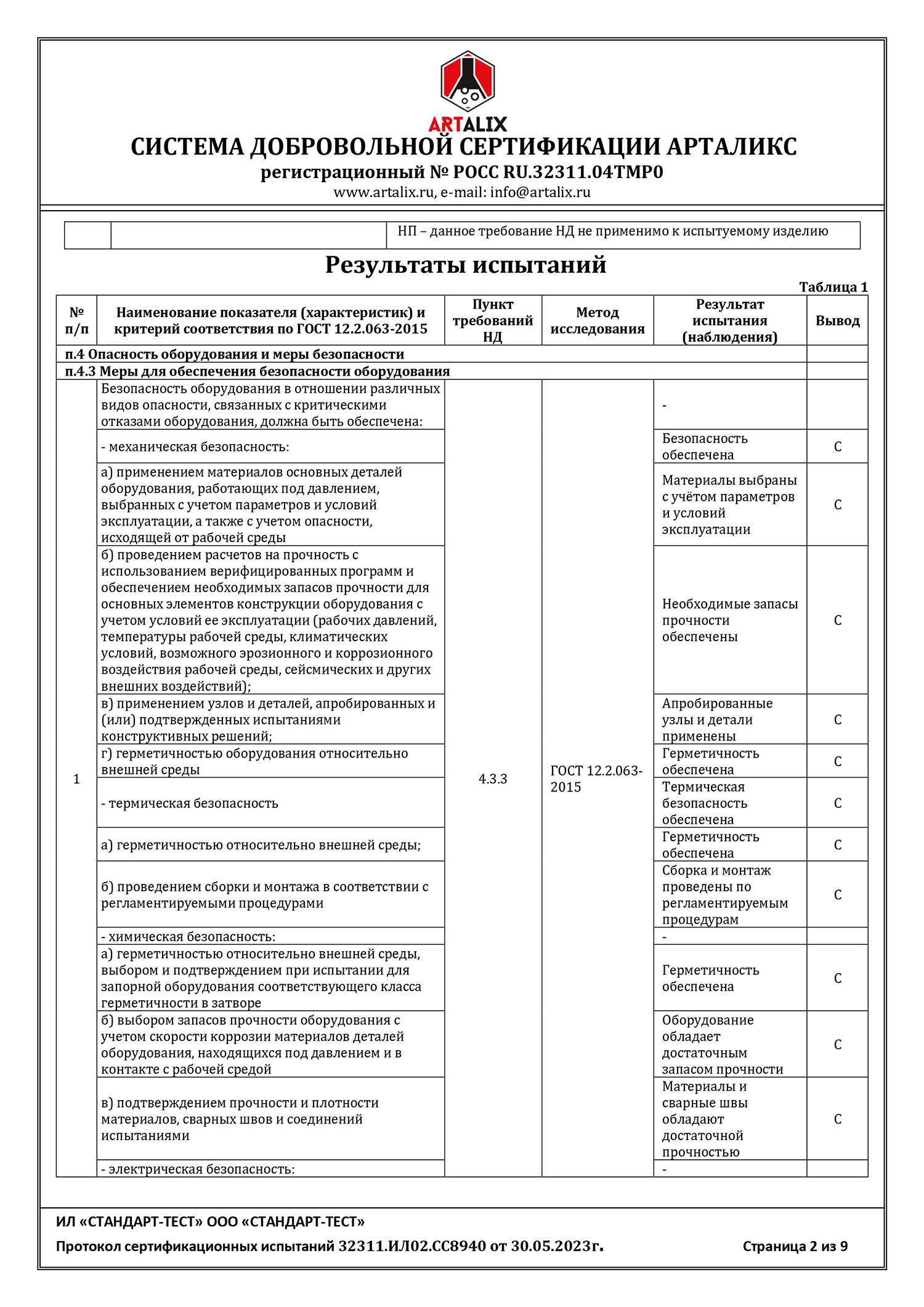

Surface technical requirements are defined by the size and number of permitted impurities. This size and quantity are strictly tested and controlled during polishing and after polishing.

Product Advantages

Design and Structural Innovations for Enhanced Reliability

The Mirror Steel Belt’s design employs a high-grade polishing technique on a robust 2B steel substrate enhanced by ESR remelting, yielding exceptional surface quality and durability. Its modular grading system from JM-0 to JM-4 allows seamless adaptation within various conveying systems and industrial setups. The belt’s construction maintains consistency in surface smoothness, crucial for thin film casting and drying processes. This structural reliability supports integration with existing industrial conveyor belts and drying systems, minimizing downtime and optimizing system compatibility.

Superior Operational Performance and Maintenance Support

Performance-wise, the Mirror Steel Belt offers ultra-low surface roughness ensuring precise film thickness and optical clarity critical in advanced manufacturing. Its resistance to impurity-related defects enhances overall product yield and reduces rework in demanding environments such as drying systems and film casting lines. Supported by comprehensive consulting, regular inspection, and professional maintenance services from Consol, this steel belt delivers extended service life and stable operation, offering measurable ROI benefits for industrial users reliant on continuous production.

Use Scenarios

Application in High-Precision Electronics Film Production

In electronic display manufacturing environments, the Mirror Steel Belt serves a pivotal role in producing thin films with stringent optical and thickness requirements. Operating within a fully automated industrial conveyor framework, this belt ensures continuous, defect-free film casting essential for LCD polarizing films and flexible display components. Its smooth surface reduces surface delay and contamination risks, meeting strict industry standards for impurity control and surface uniformity. The belt’s compatibility with precision drying and coating drying systems ensures process consistency and product quality.

Role in Advanced Polymer Film Casting and Drying Systems

Within polymer film manufacturing, the Mirror Steel Belt integrates into casting and drying lines to produce uniform polycarbonate and polypropylene films. The belt’s polished surface supports even film formation and facilitates rapid moisture removal in industrial drying systems, optimizing throughput and minimizing defects. Its adherence to strict dimensional and surface roughness specifications enhances operational efficiency and product consistency in demanding industrial conveyor-driven workflows, proving indispensable in sectors requiring high-end film materials for consumer electronics and packaging.

Quality service

In the process of using polished steel belt, it is very important to regularly inspect and maintain the steel belt regularly, because it can reduce unnecessary production.

Based on our long-term experience in this field, we can provide customers with training, consulting and maintenance services to avoid customers' worries. No matter where you are, the global sales and service system can provide you with installation and maintenance services.

For polished steel, it is very important for the surface quality of the steel belt to be polished by the environment of the welding site and the polishing process of the welding.Our company has professional knowledge, technology and equipment to provide perfect field service.

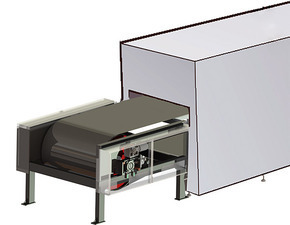

Consol also provides a flow extension machine, which we can provide consulting and service according to the parameters required by your equipment. For more information, please contact the company.

About Us

CONSOL is an international enterprise focusing on steel belt and steel belt driving system. After years of industry accumulation and continuous development, we can provide reliable steel belt and steel belt system to customers all over the world. We insist on steel belt as the basis of the core technology, seek to provide professional steel belt transmission solutions for various industries including the food industry, chemical industry, composite industry, rubber industry, and film casting industry. For Consol, quality is our only belief. The goal we pursue is to create value for our customers, solve problems pragmatically, and bring benefits and promotion to the customers. Consol is located in Guangzhou, the center city of the Pearl River Delta. By setting up branches and agent cooperation, Consol has established a customer service network covering most countries worldwide. No matter where you are, our steel belts can be delivered to you, including installation and after-sales service. Contact us now for your custom quote!

FAQ

What materials are used in the Mirror Steel Belt to ensure its surface quality?

The Mirror Steel Belt is made from polished ordinary 2B steel belts enhanced using ESR electroslag remelting and Argon-Oxygen Decarburization (AOD) technologies. This process reduces impurities, significantly improving surface smoothness and uniformity vital for applications involving industrial conveyors and high-quality film production.

Can the Mirror Steel Belt be customized for different industrial applications?

Yes, Consol offers multiple polishing grades from JM-0 to JM-4, allowing customization to meet specific surface roughness and quality requirements. This adaptability makes the Mirror Steel Belt suitable for diverse uses in drying systems, film casting, and precision conveying systems.

What installation and maintenance support does Consol provide for steel belts?

Consol Machinery Equipment Co., Ltd. offers comprehensive services including welding, polishing, professional maintenance, training, and on-site technical support. Regular inspection and professional upkeep are advised to maintain durability and performance of the Mirror Steel Belt within your industrial cooling solutions or film casting operations.

What are the typical delivery timelines for orders of the Mirror Steel Belt?

Delivery times depend on order quantity, specific polishing level, and customer requirements. For accurate scheduling, customers are encouraged to contact Consol’s sales department directly. This ensures alignment with production and shipping needs in various sectors such as drying system applications and other industrial uses.

OUR CAPABILITY

CONSOL is an international enterprise focusing on steel belt and steel belt driving system.

Keyword:

Related Products