Contact Us

E-mail info2@consolbelts.com

Phone/WhatsApp/Wechat

+86 18820135908

Oven steel belt

Oven steel belt refers to the conveyor belt on the production line of tunnel oven, which is one of the most core parts of tunnel oven...

Стальная лента

Analysis of oven band

Oven steel belt refers to the conveyor belt on the production line of tunnel oven, which is one of the most core parts of tunnel oven. It is widely used in the production process of bakery products such as cookies, biscuits, cakes and desserts and so on.The steel belt has been used as the conveyor belt of the oven for more than half a century. Up to now, the steel belt still plays an irreplaceable role and is gradually replacing the use rate of the mesh belt in the oven.

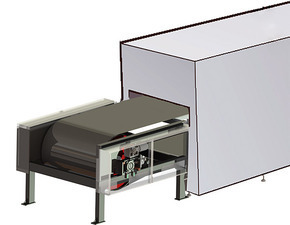

Oven steel belt conveyor system

Oven conveyor system generally consists of several parts like oven steel belt, driving ends, tension ends and all kinds of oven accessories such as steel belt tracking device, graphite bar, cast iron block, limit wheels... Many spare parts are not on the mesh belt oven, so steel belt oven is high cost not only because of the steel belt.The mesh belt oven looks like steel belt oven, but upgrading to the steel belt oven requires a lot of consideration and a lot of time and money to complete the design and transformation.

Serving life of oven steel belt

The steel belt has almost all the good working characteristics of the wire mesh belt. The most important thing is that the oven steel belt can satisfy the production of almost baking products.The only disadvantage is that the price will be a little more expensive, but the relative life is very long,normally,the general life of the oven steel belt can reach more than 5 years.After that time, the degree of matching with the equipment will be greatly influenced, the more sophisticated and reasonable equipment is more conducive to improve the life of the oven steel belt.In terms of the working condition speed of the oven steel belt, the slower speed, the longer serving life will be.The operating speed of the steel belt used for IQF freezing is the slowest, with an average speed of about 1-2m/min, so the service life of the IQF steel belt can generally reach more than 10 years.The operation speed of the steel belt used for chemical granulation is relatively fast, the fastest may reach 140m/min, so the life of the chemical steel belt is usually relatively short, with an average life of about 1-2 years.So 1 steel belt can replace the service life of 3 wire mesh belts, in the long run the price difference between the steel strip and the wire strip is very small, with the addition of many advantages of oven steel belt, why not choose a oven steel belt?

Dynamic strength of oven steel belt

The definition of fatigue limit means under a certain alternating stress, 50% of the test samples can withstand the load cycle of 2 million times. Test at 20 ℃ dry environment, the fatigue limit of parent metal is + 460 N/mm squared (Kis) 67.

Scope of supply of oven steel belt

●Length: customizable

●Width: 0~1500 mm(single brand)

●Thickness: 0.8mm-1.2mm.

●The width of the single oven band is up to 1500mm, vertical jointing more than this width,special specifications can be customized.

Weldability

Oven steel belt should be tempered after welding.TIG welding skill is the first choice.

Application scope

Suitable for cookies, Swiss roll, cake, white lover, chocolate, nuts cake, bread, Italian crispy cakes, muffins, brownie, puff, crackers, oaten cake, ginger bread, cereals, Christmas gingerbread, marin sugar, dragon card, French cake, pizza, sponge cake and other food production process.

Product Advantages

Structural and Design Engineering Benefits

The oven steel belt features a modular design allowing customizable length and width configurations to fit varied tunnel oven sizes, enhancing adaptability for different production line layouts. Its carbon steel construction ensures exceptional fatigue resistance, bolstered by TIG welding and tempering processes that guarantee robust weld joints and belt longevity. The integration of essential accessories such as graphite bars and tracking devices reduces operational wear and maintains belt alignment, minimizing downtime. This structured approach in the belt and system design optimizes integration with existing industrial conveyors, providing a flexible, scalable component suited for diverse manufacturing environments requiring robust steel belt solutions.

Performance Efficiency and User Value Proposition

Operationally, the oven steel belt maintains consistent speed regulation between 1 and 140 m/min based on baking process demands, supporting diverse product profiles with precision conveying. Its enhanced thermal conductivity ensures uniform temperature distribution, preventing hotspots and product defects. The belt’s extended service life — typically exceeding five years — contributes to lower lifecycle costs and reduced maintenance frequency, which is critical for high-demand manufacturing schedules. This reliable performance supports end users in achieving improved productivity and operational stability within tight bakery production timelines and complex drying systems. The usability benefits also include easy integration and compatibility with standard conveyor drive systems and controls, enhancing system efficiency.

Use Scenarios

Application in Tunnel Oven Baked Goods Manufacturing

Within food production facilities specializing in baked products such as cookies, biscuits, and cakes, the oven steel belt functions as a core conveying system component enabling reliable transport through tunnel ovens. The steel belt’s thermal resistance and fatigue strength ensure steady operation under high-temperature conditions, while the integrated tracking system maintains belt alignment, preventing production interruptions. This allows manufacturers to maintain consistent baking quality and throughput rates. The belt’s compatibility with existing industrial conveyors facilitates streamlined system upgrades, providing an efficient solution for baking lines requiring robust, heat-resistant conveyor belts integrated within comprehensive industrial cooling solutions to optimize the entire baking cycle.

Role in Continuous Drying and Cooling Production Lines

In industrial environments where drying systems are crucial—such as bakery product lines involving moisture reduction—the oven steel belt operates as a high-performance conveyor compatible with continuous drying and cooling equipment. Its carbon steel composition provides superior heat resistance necessary for extended exposure to the drying process, while its customizable size options allow adaptation to various tunnel oven and dryer dimensions. The steel belt supports seamless product flow through drying systems, ensuring precise temperature and moisture control. Its integration reduces manual intervention and aligns with automated process controls, facilitating enhanced operational efficiency and maintaining the integrity of baked goods throughout post-baking steps, aligning with expectations for reliable industrial conveyor belts in complex production ecosystems.

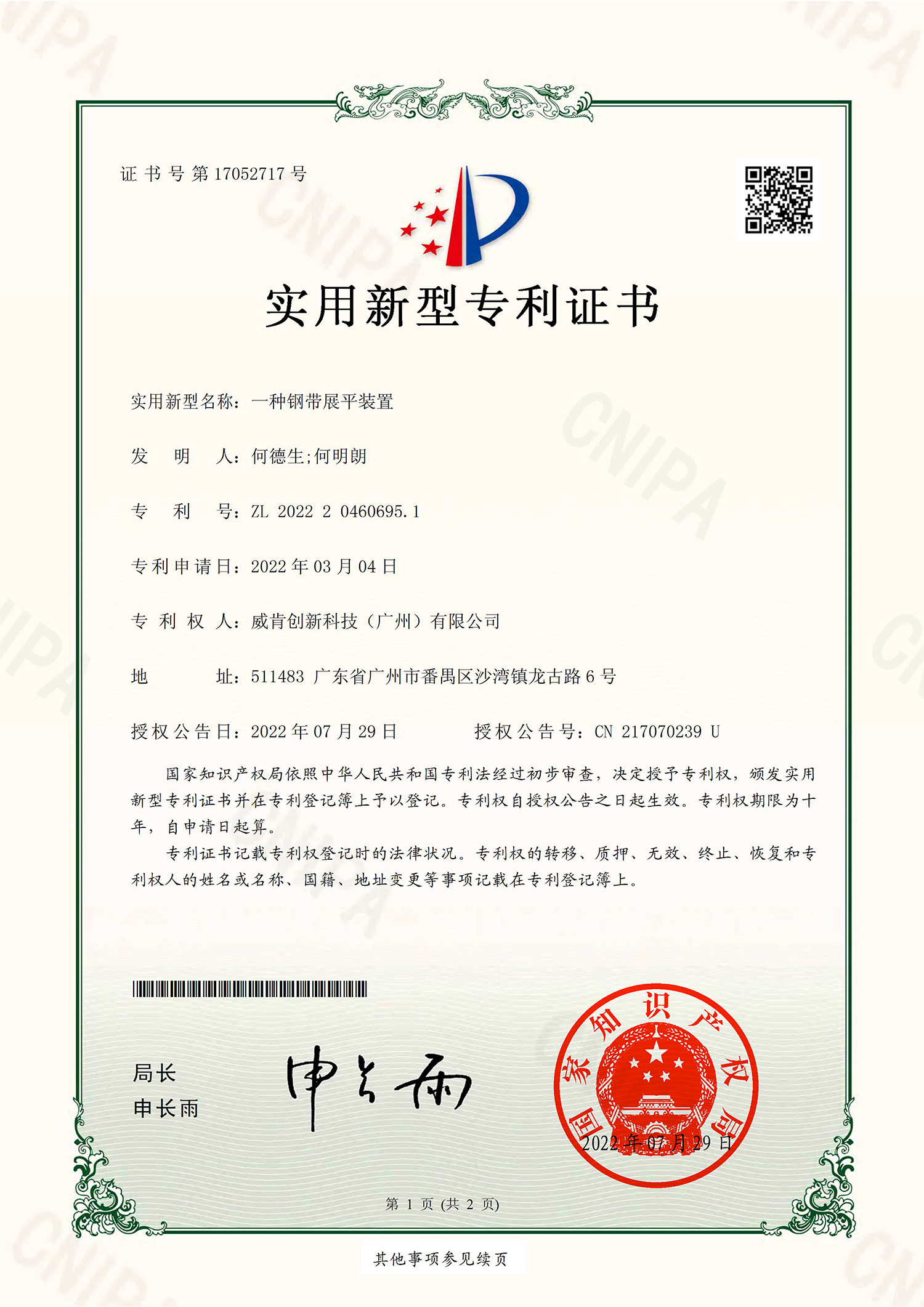

About Us

CONSOL is an international enterprise specializing in steel belts and steel belt driving systems. With years of industry experience and continuous development, we provide reliable steel belts and belt systems to customers worldwide. We focus on steel belts as our core technology, delivering professional steel belt transmission solutions across industries such as food, chemical, composite, rubber, and film casting.

Located in Guangzhou, the Pearl River Delta’s center, CONSOL has established a global customer service network through branches and agent partnerships. Our steel belts are deliverable worldwide, including installation and comprehensive after-sales support. Contact our technical team for expert help!

FAQ

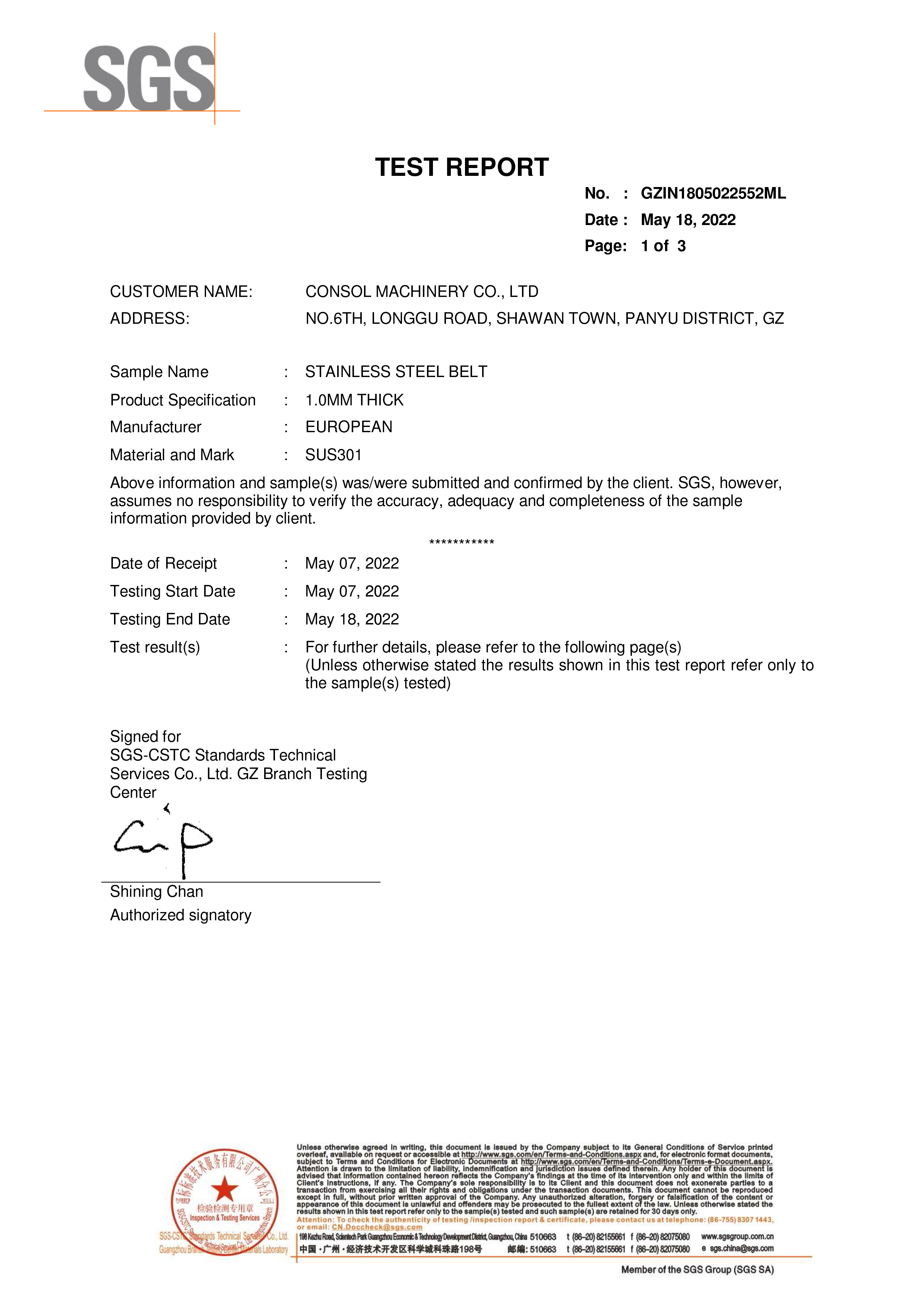

What materials are used to manufacture the oven steel belt?

The oven steel belt is constructed from high-quality carbon steel, chosen for its excellent heat resistance and fatigue strength. This ensures durability and consistent performance in demanding baking environments. The belt is welded using TIG welding and tempered to maintain strength throughout its operational life in various industrial conveyor applications.

Can the oven steel belt be customized to fit specific conveyor dimensions?

Yes, the oven steel belt is highly customizable in length, width, and thickness. It supports widths up to 1500mm in a single band, with vertical jointing available for larger widths. Thickness ranges from 0.8mm to 1.2mm to accommodate different baking and conveying system requirements, allowing seamless integration with existing production lines.

What is involved in the installation and maintenance of the oven steel belt?

Installation includes proper alignment with tunnel oven conveyors, supported by included accessories such as tracking devices and graphite bars for stable operation. Regular inspection ensures the TIG-welded tempered joints remain intact, while maintenance focuses on monitoring wear, ensuring the belt’s longevity beyond five years in typical baking lines.

How does CONSOL handle international shipping and after-sales support for steel belts?

CONSOL ships oven steel belts globally from its base in Guangzhou, China, fulfilling orders with prompt logistics and professional packaging for safe delivery. We provide full after-sales support including technical consultation and service, ensuring operational stability for customers worldwide using our industrial cooling solutions and conveyor products.

OUR CAPABILITY

CONSOL is an international enterprise focusing on steel belt and steel belt driving system.

Category:

Keyword:

Related Products