-

-

-

BLOG&EVENT

-

ABOUT US

Contact Us

E-mail info2@consolbelts.com

Phone/WhatsApp/Wechat

+86 18820135908

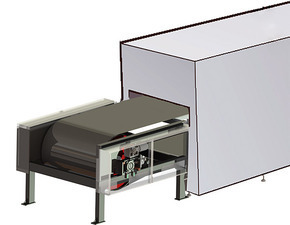

Stainless Steel Belt MS1650

The CONSOL MS1650 belt grade is made of low martensitic stainless steel of type 15-7 PH

Стальная лента

The CONSOL MS1650 belt grade is made of low carbon,martensitic, precipitation hardened, stainless steel of type 15-7 PH and is characterised by:

• Excellent static strength

• Excellent fatigue strength

• Good corrosion resistance

• Very good wear resistance

• Very good repairability

CONSOL MS1650 is a high strength steel with excellent mechanical properties.This, in combination with good corrosion resistance, makes it the ideal choice for applications in very harsh conditions. Widely used in industries of artificial board, artificial marble,composite materials and so on.

Corrosion resistance

MS1650 shows good corrosion resistance under normal air conditions. However, the steel belt should not be applied to the environment with hydrochloric acid.

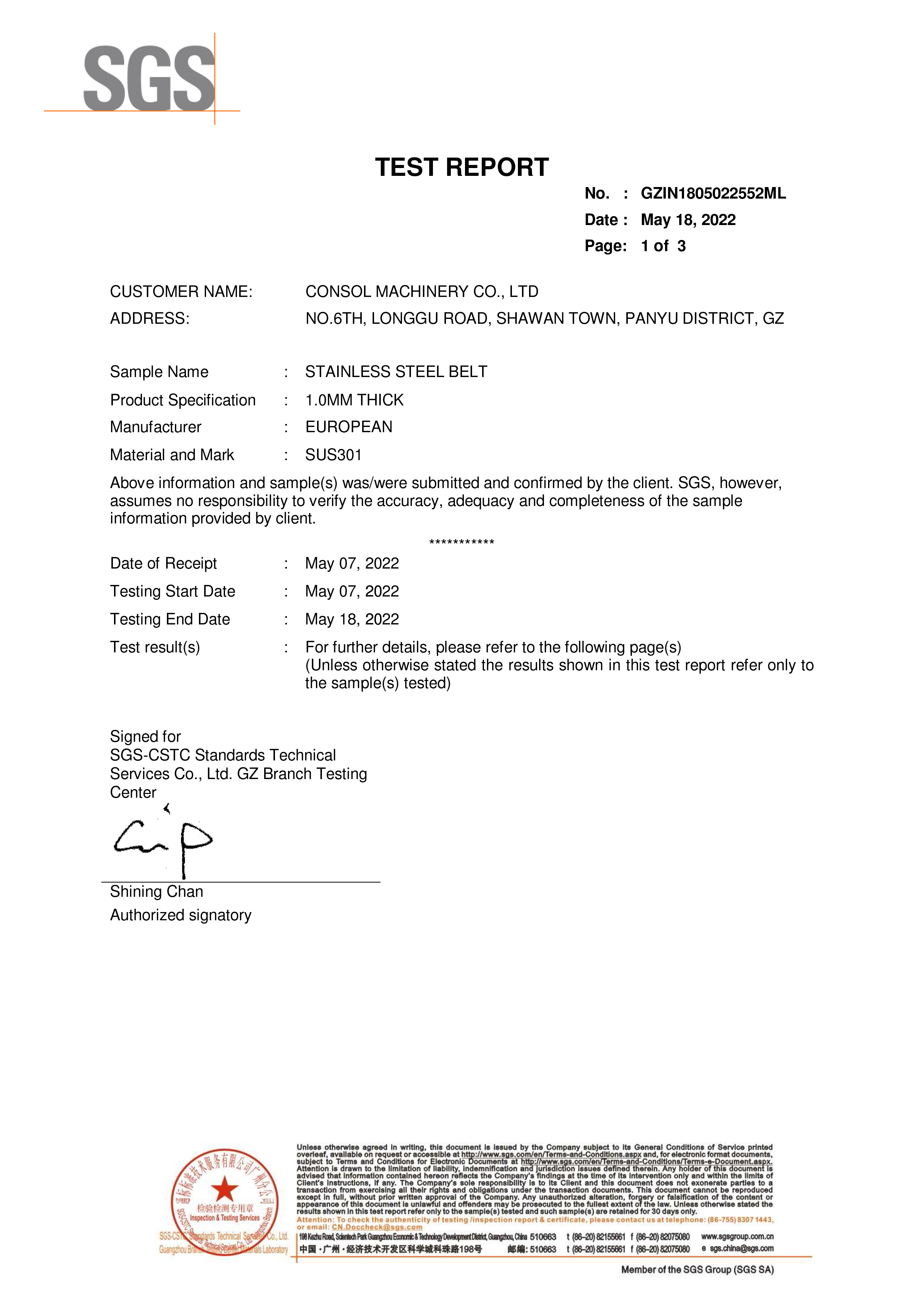

Chemical component | |||||||||

C | Si | Mn | P | S | Cr | Ni | Cu | Ti | Mo |

0.073 | 1.53 | 0.69 | 0.0062 | 0.002 | 13.56 | 7.09 | 0.71 | 0.48 | 0.88 |

Weldability

MS1650 steel belt has good welding performance, and the weld has good strength and toughness. The welding wire is the best for ER632 and ER630, and the ideal welding method is TIG welding. Even if there is no weld heat treatment, there is good strength. Guangzhou kenshao has the ability to heat heat treatment on site, and the welding coefficient is close to 0.9 by welding heat treatment.

Scope of supply

Length: customizable

Width: 1000/1200/1500/2000.

Thickness: 1.0/1.2/1.5/2.0

The maximum width of the single steel band is 1500mm.Special specifications can be customized.

OUR CAPABILITY

CONSOL is an international enterprise focusing on steel belt and steel belt driving system.

Related Products

19, No.63 jieyuan road, Shawan town, Panyu dist, Guangzhou, China

Request Quote

We will contact you within one working day. Please pay attention to your email.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.