Contact Us

E-mail info2@consolbelts.com

Phone/WhatsApp/Wechat

+86 18820135908

Steelbelt-Film casting

Good thermal conductivity, high efficiency

Стальная лента

Special steel strip for film forming

Nowadays, with more and more new films being used in people's lives. There are many steel strip casting systems and press systems that do not have industry standards, resulting in uneven film quality. Through continuous exploration, we found that in addition to the technical formula, the steel strip directly affects the thickness, uniformity, stripping, color, transparency and other properties of the film.

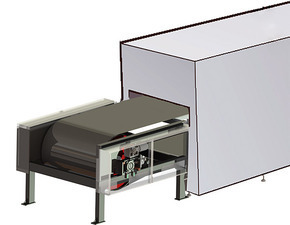

Steel strip casting drying system

The water-soluble material is evenly coated on the steel belt conveyor system through the spreader. The steel strip then transports the material to the oven heated by thermal oil or electric heating tube, and the water vapor is carried away by the air circulation dehumidification system. The material on the steel belt is dried and solidified into a uniform thin layer, which is finally scraped off the steel belt by the scraper and collected by the winder.

CONSOL film production lines accept non-standard customization and can be used in a wide range of film production processes to ensure superior quality. Whether the material is liquid, paste or viscous, CONSOL can customize the production line products and technologies according to the different requirements of customers.

Continuous production and high efficiency are the core advantages of the steel strip casting system, which is conducive to environmental protection and flexible integration of multiple production processes such as pressure, temperature and cooling in the same production line. CONSOL has extensive experience and expertise in thin film coating and can provide polished steel strips, efficient coating equipment, engineering design and after-sales service.

In the production process, humidity control is also important, because poor humidity control can lead to the surface of the product "peeling", thus extending the production time, and even affecting the quality of the product. In addition to temperature and humidity, air flow and pressure also affect the efficiency of the entire production. Different heat treatment processes are suitable for different products.

Advantages

● Good thermal conductivity, high efficiency

● Good fatigue resistance, not easy to plastic tensile

● No pollution, good corrosion resistance

● Hard and smooth surface, easy to separate the material from the steel strip

● High temperature resistance, easy to clean and disinfect, no rust.

Welding technique

The complete after-sales service is indispensable, and regular inspection and maintenance of the steel strip is very important, as this reduces unnecessary production disruptions. In addition, the welding environment and polishing treatment are also important for the surface quality of the entire steel strip. CONSOL has a comprehensive training, consulting and solution system.

About CONSOL

Industry Positioning

CONSOL is a leading international enterprise specializing in steel belts and steel belt driving systems, providing reliable solutions to customers worldwide.

Core Manufacturing Capabilities and Quality Assurance

Product Range: We offer a diverse array of steel belts, including carbon steel belts, stainless steel belts, perforated steel belts, super mirror steel belts, precision steel belts, and martensitic stainless steel belts.

Application Areas: Our products are utilized across various industries such as oil & gas, chemical, food, precision machinery, film casting, woodworking, and composite industries.

Quality Commitment: We adhere to stringent quality standards to ensure our products meet the highest industry requirements.

Production Strength

Located in Guangzhou, the heart of the Pearl River Delta, CONSOL has established a robust manufacturing base, enabling us to serve clients efficiently across the globe.

Sustainability Measures

Our steel belts are designed for durability and recyclability, contributing to sustainable industrial practices.

Customer Collaboration Process

We have built a comprehensive sales and after-sales service system, coordinating installation services near our clients' facilities to ensure optimal service quality.

Global Service Capability

Over the past decade, CONSOL has exported products to more than 30 countries, including the USA, Russia, Canada, Korea, South Africa, Iran, Turkey, Ukraine, Saudi Arabia, Spain, Holland, Brazil, Malaysia, Thailand, India, Pakistan, the Philippines, Indonesia, and Vietnam.

FAQ

Who are we?

CONSOL is an international enterprise focusing on steel belts and steel belt driving systems, committed to providing reliable solutions to customers worldwide.

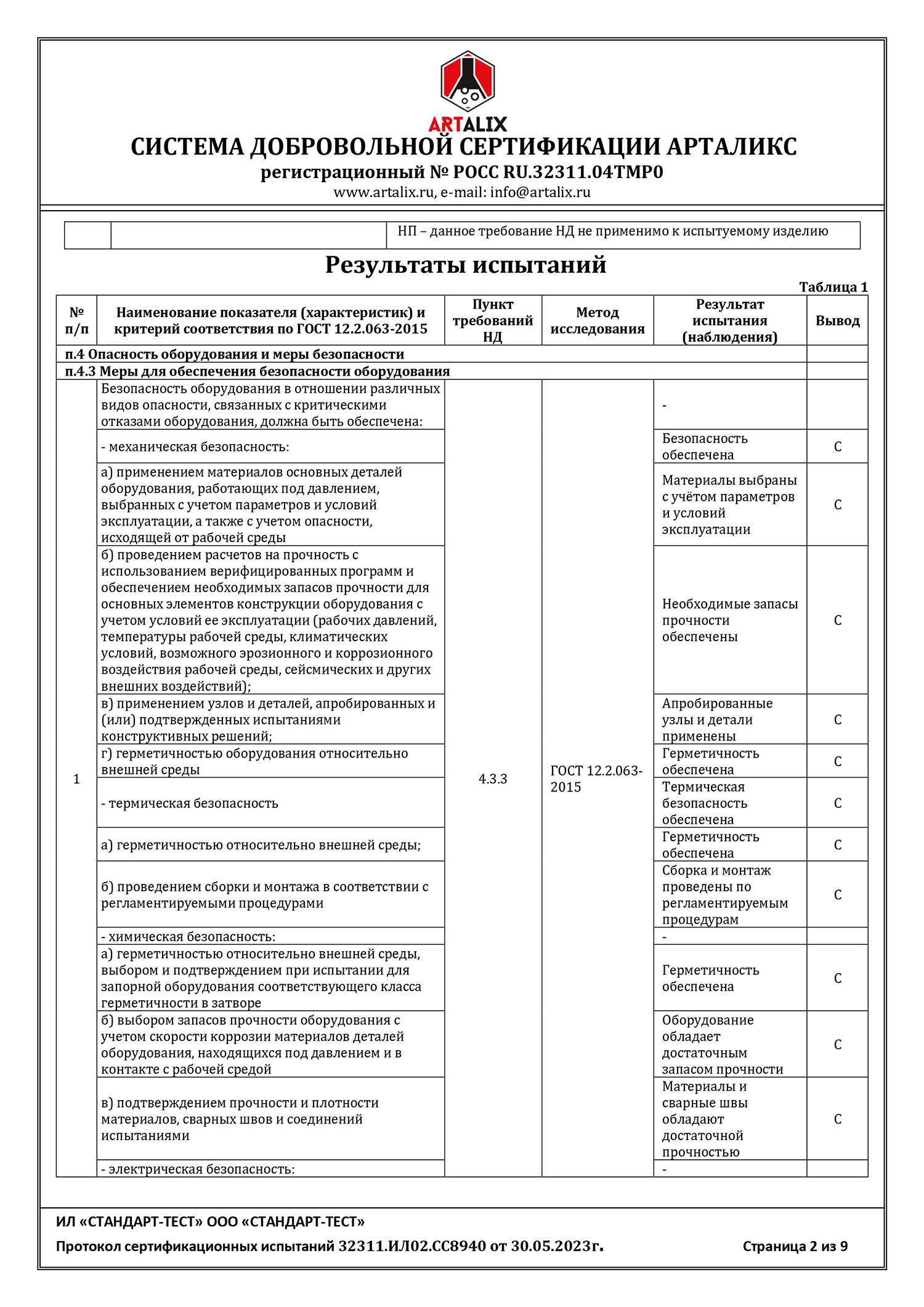

How can we guarantee quality?

We adhere to strict quality control processes and hold certifications such as SGS, CE, and ISO 9001 to ensure our products meet international standards.

What can you buy from us?

Our product offerings include various types of steel belts and conveyor systems suitable for multiple industrial applications.

Why should you buy from us and not from other suppliers?

With a decade of experience exporting to over 30 countries and a commitment to quality and customer service, CONSOL stands out as a reliable partner for your industrial needs.

What services can we provide?

We offer comprehensive services, including after-sales support, seamless welding technology, edge shaping, conveyor system rebuilding, and V-rope sticking, ensuring our clients receive end-to-end solutions.

OUR CAPABILITY

CONSOL is an international enterprise focusing on steel belt and steel belt driving system.

Keyword:

Related Products