-

-

-

BLOG&EVENT

-

ABOUT US

Contact Us

E-mail info2@consolbelts.com

Phone/WhatsApp/Wechat

+86 18820135908

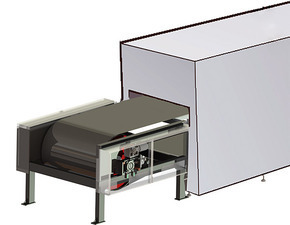

Water soluble film casting

Water soluble film casting system is based on steel belt tunnle dryer, the wet material will be extruded from feeder and go through the steel belt tunnel oven...

Транспортная система

Film casting drying system

Watered materials are evenly spread on the steel belt conveyor system through spread machine. Then steel belt conveys the materials to the drying tunnel furnace which is heated by PTC and quartz heating pipe, water vapor is carried away by the air circulation dehumidification system. Materials on the steel belt is dried and solidified into a uniform thin layer, and finally scraped off the steel belt by the scraper and collected by winding machine.

CONSOL film coating production line is very flexible, widely used for all kinds of coating technology and materials, to ensure excellent quality, Whether the material is liquid, mushy or sticky, it is available for CONSOL to customize production line according to different requirements of customers' products and technology.

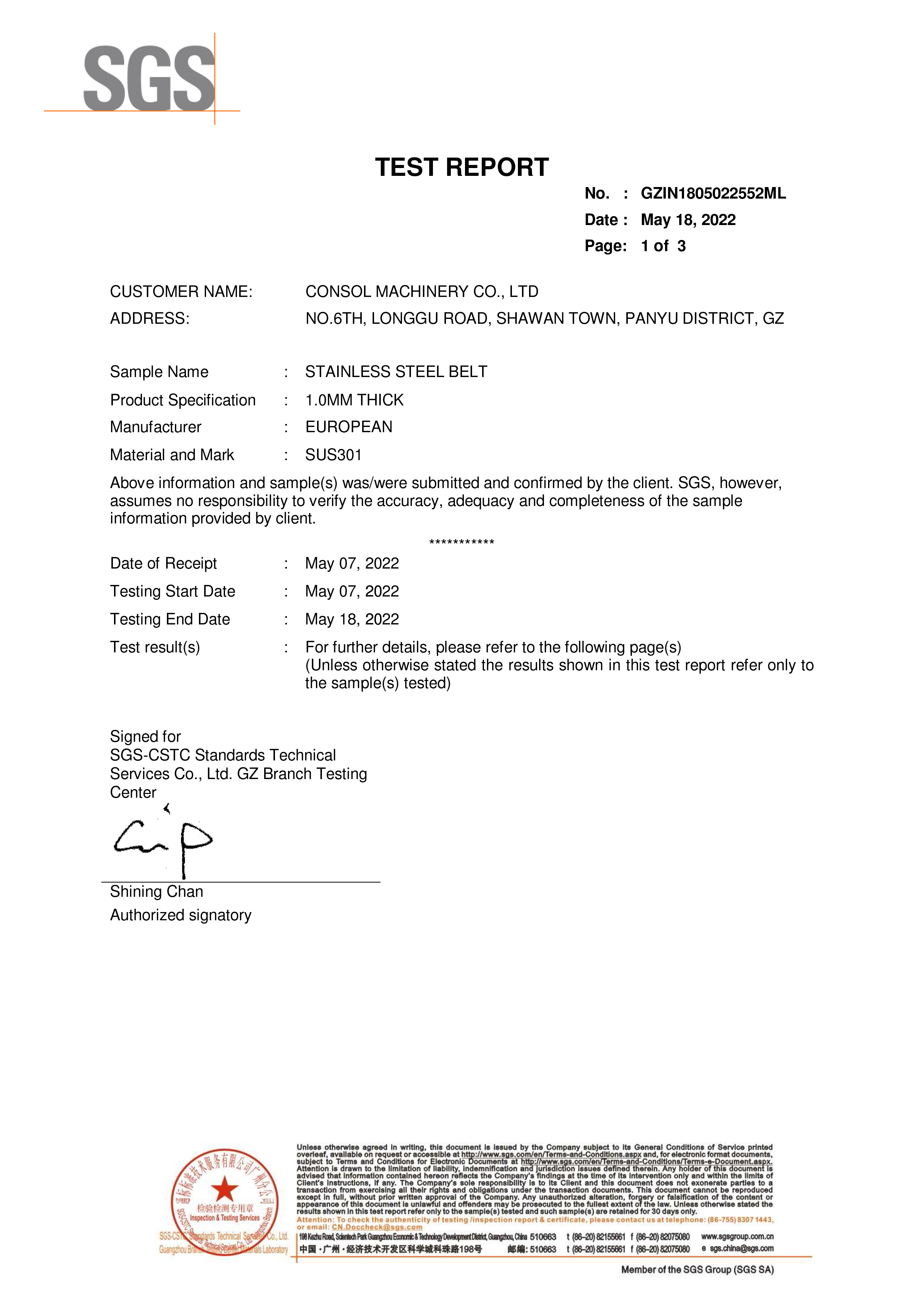

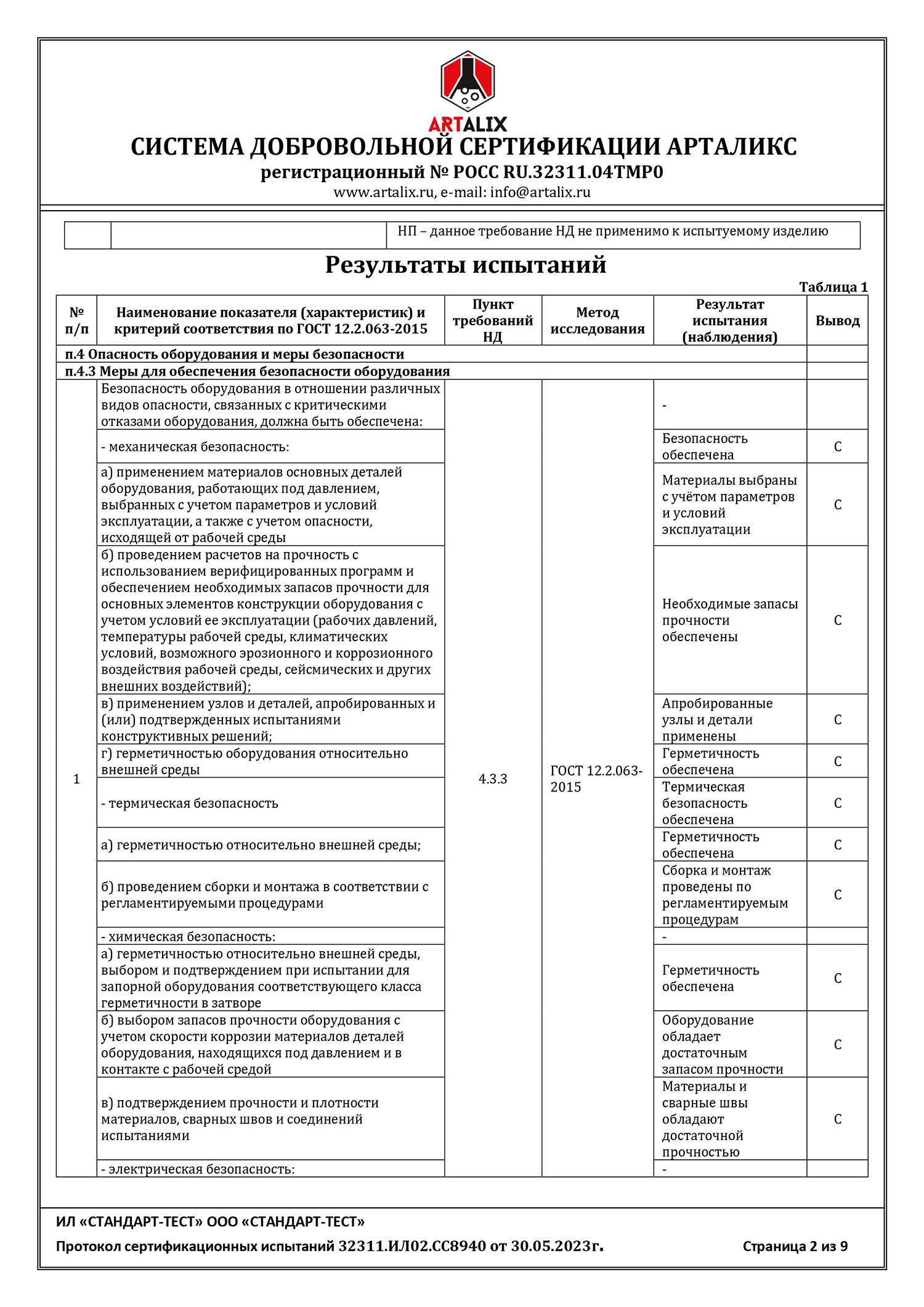

Steel belt dryers extract all moisture from sheets, powders, flakes, fibers or wet materials such as sludge prior to production. To dry the material efficiently, air is guided through a perforated belt. In dryers without perforated belts, the hot air flows to the material along the production area and dries the material. The raw material is also dehydrated on the inside by using efficient types of heating such as hot air, hot water or electrical heat. The stainless steel belts made in Consolallow high temperatures used for drying.

OUR CAPABILITY

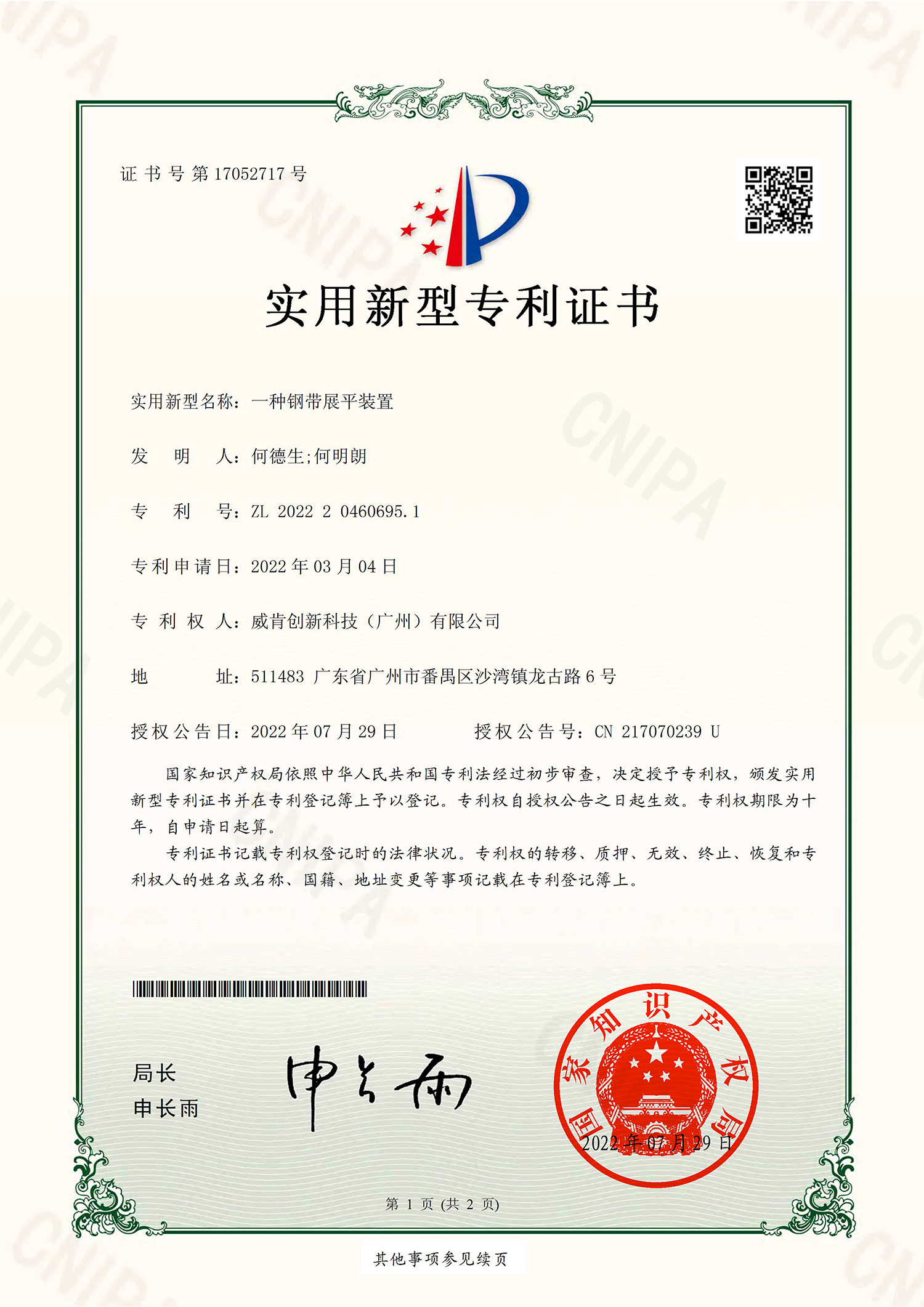

CONSOL is an international enterprise focusing on steel belt and steel belt driving system.

Category:

Keyword:

Related Products

19, No.63 jieyuan road, Shawan town, Panyu dist, Guangzhou, China

Request Quote

We will contact you within one working day. Please pay attention to your email.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.