Contact Us

E-mail info2@consolbelts.com

Phone/WhatsApp/Wechat

+86 18820135908

Steel belt for chocolate

Stainless Steelbelt is the core technology in candy/chocolate granulation/ pelleting production process.

Стальная лента

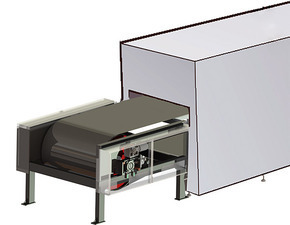

Stainless steelbelt-chocolate

-The core technology in candy/chocolate production process

The melt chocotale drop on the steel belt and conveyed to the cooling zone and solidified into granulation. Steel belt has a great influence in the chocolate cooling process, we can product almost any length/width steel belt,apply to the system from material to production.Not only we offer steel belt replacing service,but also support steel conveyor system for equipment manufacturer including drums,supports,tracking devices and clean scrapers.

Cooling/Curing

We can design,produce and install all kinds of cooling systems,which are clean and efficiency by using cooling air or cooling water. Stainless steel belt has a long service life for chocolate production line.

Granulation

Our chocolate granulation system is a continues solution from melting to cure,it can achieve mass production for quality granulation,and adapt for high viscosity product up to 50,000mPas,sizes from 3 to 15mm. Stainless steel belt can reach speed up to 60m/min .

Pouring

The steel belt also can be used for curing caramel and candy.Furthermore,we provide steel belt for chocolate equipment manufacture,but also provide the whole system equipment including feeding device,strip making device and cutter/flaker.

Characteristic of Stainless steel belt-chocolate AS1200

●Good flatness.

●Outstanding straightness and tracking.

●Corrosion resistance.

●Long serving life.

●Excellent mechanical strength.

●Perfect welding quality.

●V-type adhesive tape.

●Different requirements for general products.

Scope of supply

Length:Customizable

Width:2000mm(No merging)

Thickness:0.4/0.5/0.8 / 1.0 / 1.2 mm

The thermal properties of austenitic stainless steel AS1200 steel belt, coupled with its hard, durable and smooth surface, makes it very suitable for handling high temperature, high viscosity, oil, sharp or rough materials, and is widely used in chocolate cooling and other fields.

Unmatched Efficiency in Chocolate Production

The Consol Stainless Steel Belt is a pivotal component in the chocolate cooling and granulation process, redefining efficiency in industrial settings. This steel belt is engineered to handle high temperatures and viscosities, ensuring that chocolate is cooled and solidified seamlessly. Its robust design supports mass production, making it an indispensable asset for manufacturers aiming to optimize their chocolate production lines. With customizable dimensions, the stainless steel conveyor belt adapts to various operational needs, providing flexibility and precision in every batch. The metal conveyor belt ensures consistent performance, reducing downtime and enhancing productivity.

Precision and Reliability for High-Quality Output

Built for precision and performance, the Consol Stainless Steel Belt offers outstanding mechanical strength and corrosion resistance, crucial for maintaining the integrity of chocolate products. Its smooth surface and excellent welding quality ensure that the chocolate granulation process is uninterrupted and efficient. The steel belt features a V-type adhesive tape for superior tracking and straightness, minimizing the risk of product defects. This stainless steel conveyor belt is designed to withstand the rigors of continuous operation, delivering reliable results that meet the high standards of the confectionery industry. The metal conveyor belt is a testament to Consol's commitment to quality and innovation.

Scalable Design to Meet Growing Demand

As demand for chocolate products increases, the Consol Stainless Steel Belt offers a scalable solution to meet production needs. Its customizable length and width options allow manufacturers to expand their operations without compromising on quality. The steel belt is suitable for handling a wide range of materials, including high viscosity and sharp or rough substances, making it versatile for various applications beyond chocolate cooling. The stainless steel conveyor belt supports future-proofing strategies, ensuring that production lines can adapt to evolving market demands. With its durable construction, the metal conveyor belt is an investment in long-term operational success, providing manufacturers with the tools they need to thrive in a competitive industry.

Product Advantages

1.Enhanced Production Efficiency

The Consol Stainless Steel Belt is engineered to optimize chocolate cooling and granulation, handling high temperatures and viscosities with ease. This steel belt supports mass production, ensuring seamless solidification of chocolate, which is crucial for maintaining high throughput in industrial settings.

2.Customizable for Diverse Needs

With customizable dimensions, the stainless steel conveyor belt adapts to various operational requirements, offering flexibility and precision in every batch. This adaptability makes the metal conveyor belt an ideal choice for manufacturers looking to tailor their production lines to specific demands.

3.Superior Durability and Performance

Built with outstanding mechanical strength and corrosion resistance, the Consol Stainless Steel Belt maintains the integrity of chocolate products. Its robust design ensures consistent performance, reducing downtime and enhancing productivity, making it a reliable asset in any production line.

4.Precision Tracking and Straightness

The steel belt features a V-type adhesive tape for superior tracking and straightness, minimizing the risk of product defects. This ensures that the chocolate granulation process is uninterrupted and efficient, meeting the high standards of the confectionery industry.

5.Scalable for Future Growth

As demand for chocolate products increases, the stainless steel conveyor belt offers a scalable solution to meet production needs. Its durable construction supports future-proofing strategies, allowing production lines to adapt to evolving market demands, ensuring long-term operational success.

About CONSOL

Industry Positioning

CONSOL is a leading international enterprise specializing in steel belts and steel belt driving systems, providing reliable solutions to customers worldwide.

Core Manufacturing Capabilities and Quality Assurance

Product Range: We offer a diverse array of steel belts, including carbon steel belts, stainless steel belts, perforated steel belts, super mirror steel belts, precision steel belts, and martensitic stainless steel belts.

Application Areas: Our products are utilized across various industries such as oil & gas, chemical, food, precision machinery, film casting, woodworking, and composite industries.

Quality Commitment: We adhere to stringent quality standards to ensure our products meet the highest industry requirements.

Production Strength

Located in Guangzhou, the heart of the Pearl River Delta, CONSOL has established a robust manufacturing base, enabling us to serve clients efficiently across the globe.

Sustainability Measures

Our steel belts are designed for durability and recyclability, contributing to sustainable industrial practices.

Customer Collaboration Process

We have built a comprehensive sales and after-sales service system, coordinating installation services near our clients' facilities to ensure optimal service quality.

Global Service Capability

Over the past decade, CONSOL has exported products to more than 30 countries, including the USA, Russia, Canada, Korea, South Africa, Iran, Turkey, Ukraine, Saudi Arabia, Spain, Holland, Brazil, Malaysia, Thailand, India, Pakistan, the Philippines, Indonesia, and Vietnam.

FAQ

Who are we?

CONSOL is an international enterprise focusing on steel belts and steel belt driving systems, committed to providing reliable solutions to customers worldwide.

How can we guarantee quality?

We adhere to strict quality control processes and hold certifications such as SGS, CE, and ISO 9001 to ensure our products meet international standards.

What can you buy from us?

Our product offerings include various types of steel belts and conveyor systems suitable for multiple industrial applications.

Why should you buy from us and not from other suppliers?

With a decade of experience exporting to over 30 countries and a commitment to quality and customer service, CONSOL stands out as a reliable partner for your industrial needs.

What services can we provide?

We offer comprehensive services, including after-sales support, seamless welding technology, edge shaping, conveyor system rebuilding, and V-rope sticking, ensuring our clients receive end-to-end solutions.

OUR CAPABILITY

CONSOL is an international enterprise focusing on steel belt and steel belt driving system.

Keyword:

Related Products