Contact Us

E-mail info2@consolbelts.com

Phone/WhatsApp/Wechat

+86 18820135908

Sulphur granulation

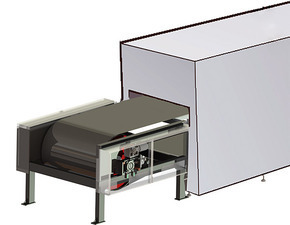

Sulphur granulation system refers to pastillator machine for sulphur,this kind of machine is one of steel belt cooler.

Транспортная система

Consol Sulphur granulation refers to pastillator machine for sulphur, this kind of machine is one of steel belt cooler. Sulphur pastilles have many advantages such as uniform size, non-dust, easy to measure and transport, not easy to break...Sulphur granulation system is also available for chemical fertilizer products like urea, sulphur bentonite and so on.

Sulfur is one of the important inorganic pesticides.The product is yellow solid or powder with obvious smell and can be volatilized.Sulfur water suspension is slightly acidic, insoluble in water, and reacts with alkali to form polysulfide.Sulfur dioxide gas is produced by combustion.In the production of sulfur is often processed into rubber suspension used for the prevention and control of pests and diseases, it is safe to people, livestock, not easy to cause crop damage.

A pump transports the mixture from the mixing vessel via a filter into the feeding system. The system consists of a heated cylindrical stator which is supplied with liquid product, and a perforated rotating shell that turns concentrically around the stator, depositing sulphur drops across the whole operating width of the steel belt.

The circumferential speed of the feeding system is synchronised with the speed of the belt: drops are therefore deposited without deformation. Heat released during solidification and cooling is transferred by the stainless steel belt to cooling water sprayed against the belt underside. This water is collected in tanks and returned to the recooling plant; at no stage does it come into contact with the sulphur.

At the cooler end, pastilles are taken off with a discharge knife and pass via a chute to a collecting belt for further processing. To eliminate the possibility of damage to the pastilles during discharge, a silicon-based release agent is applied to the steel belt as a thin film by means of a roller system. An automatic filling system ensures that sufficient quantity of the release agent is always held in the tank.

Advantages of Process

• Product quality - uniform shaped pastille

• Solidification - well defined cooling time

• Heat transfer - indirect, no contact between product and cooling medium

• Flexibility - rapid changeover to partial operation without changes in quality: modular design means each unit can be operated individually

Utilities

• Low power consumption

• Low water consumption by use of a recooling system

• Low compressed air and instrument air consumption

• Low steam consumption

Many soils throughout the world suffer from rising pH levels. The plant nutrient sulphur has proved extremely useful for increasing soil acidity or lowering soil pH. Global demand for sulphur for agricultural use has therefore grown rapidly in recent years. Elemental sulphur, although available in large quantities, cannot be used as nutrient, mainly because it is not soluble in water, a granule of elemental sulphur takes a long time to dissolve into the soil...

So sulphur bentonite pastille is developed. Mix sulphur and bentonite with a certain proportion, and use the same principle granulation process, people can get the better sulphur complex fertilizer for agriculture.

Precision Engineering for Consistent Granulation

The CONSOL Sulphur Granulation system is a high-performance pastillator machine engineered for precise control over droplet size and pastille shape. As an advanced granulator machine, it transforms molten sulphur into dust-free, solid pastilles, critical for applications requiring safety and uniformity.

Efficient Belt Cooling for Industrial Scale Solidification

Utilizing a stainless steel belt and indirect cooling via water spray, this industrial granulator achieves rapid heat dissipation. This makes it the ideal pastillator setup for continuous, high-capacity granulation processes in chemical and agricultural industries.

Multi-Material Capability for Versatile Operations

Beyond sulphur, the pastillator machine is suitable for urea, sulphur bentonite, and other granular fertilizers. This flexibility makes it a go-to solution for granulator manufacturers looking to serve multiple markets with one system.

Robust and Easy-to-Maintain Structure

Built with high-grade materials, this industrial granulator offers minimal wear parts and an accessible structure, reducing maintenance efforts. Its reliability is why it’s favored by global granulator manufacturers in need of round-the-clock operation.

Streamlined User Interface for Operational Ease

With intuitive controls, operators can easily monitor and adjust process parameters. This granulator machine design minimizes operator errors and ensures consistent results, ideal for B2B environments demanding productivity and efficiency.

Product Advantages

- High Precision and Quality: This pastillator machine ensures consistent pastille size, reducing fines and dust.

- Wide Application Compatibility: Suitable for sulphur, urea, and specialty chemicals, it supports diverse industrial granulator needs.

- Durability and Low Maintenance: A rugged granulator machine design ensures long-term use with minimal service requirements.

- Enhanced Cooling System: The water-cooled steel belt boosts performance across all pastillator operations.

- Preferred by Granulation Professionals: Trusted by top granulator manufacturers worldwide for its stability and flexibility.

About CONSOL

Industry Positioning

CONSOL is a leading international enterprise specializing in steel belts and steel belt driving systems, providing reliable solutions to customers worldwide.

Core Manufacturing Capabilities and Quality Assurance

Product Range: We offer a diverse array of steel belts, including carbon steel belts, stainless steel belts, perforated steel belts, super mirror steel belts, precision steel belts, and martensitic stainless steel belts.

Application Areas: Our products are utilized across various industries such as oil & gas, chemical, food, precision machinery, film casting, woodworking, and composite industries.

Quality Commitment: We adhere to stringent quality standards to ensure our products meet the highest industry requirements.

Production Strength

Located in Guangzhou, the heart of the Pearl River Delta, CONSOL has established a robust manufacturing base, enabling us to serve clients efficiently across the globe.

Sustainability Measures

Our steel belts are designed for durability and recyclability, contributing to sustainable industrial practices.

Customer Collaboration Process

We have built a comprehensive sales and after-sales service system, coordinating installation services near our clients' facilities to ensure optimal service quality.

Global Service Capability

Over the past decade, CONSOL has exported products to more than 30 countries, including the USA, Russia, Canada, Korea, South Africa, Iran, Turkey, Ukraine, Saudi Arabia, Spain, Holland, Brazil, Malaysia, Thailand, India, Pakistan, the Philippines, Indonesia, and Vietnam.

FAQ

What materials can the CONSOL Sulphur Granulation system process?

The Sulphur granulation system is designed for molten sulphur but also supports multi-material use such as urea and sulfur bentonite, making it versatile for various industrial granulation needs.

How does the steel belt cooling system work in the pastillator machine?

The system uses indirect cooling by spraying water beneath a stainless steel belt while the molten sulphur solidifies. This ensures dust-free, uniform pastilles and prevents water contact with the product in the pastillator machine.

Can CONSOL customize the granulator machine to specific production requirements?

Yes, the system features modular operation and adjustable parameters for precise control over droplet size and pastille shape, enabling customization to fit unique process and scalability needs.

What after-sales and installation support does CONSOL provide for the steel belt granulator?

CONSOL offers coordinated installation services near your plant and comprehensive after-sales support, ensuring reliable operation and maintenance for its steel belt granulator and related systems.

OUR CAPABILITY

CONSOL is an international enterprise focusing on steel belt and steel belt driving system.

Related Products