Contact Us

E-mail info2@consolbelts.com

Phone/WhatsApp/Wechat

+86 18820135908

Precision Steelbelt

Good resistance to corrosion, heat resistance and abrasion resistance

Стальная лента

High precision steel belt

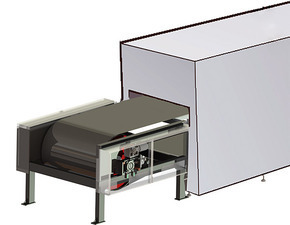

The precision steel belt provided by Consol is mainly made of specially customized stainless steel belts and carbon steel belts, and the real positioning holes are divided into single row and double row. The hole shapes are mostly round or long-waist.

Synchronous wheel

The material of the synchronous wheel is decided according to different working environment and requirements, the common material is stainless steel, aluminum and non-metallic wear-resistant materials, the belt wheel is mostly cylindrical, i-shaped design.Synchronous wheel generally has a certain rule of convex teeth or groove, their appearance is more like a half - round ball, long waist.

Precision steel belt basic material characters

Stainless steel: good wear resistance, good corrosion resistance, high mechanical strength, it is the ideal choice, the only disadvantage is high cost.

Carbon steel: wear - resistant, easy to rust, must do rust - proof treatment.

Aluminum: light and free from rust, requiring a hard chrome finish to improve the wear resistance of the surface.

Non-metallic materials: materials with certain wear resistance and high density can be used for belt wheel.

At the same time of choosing rotter steel belt, it is better to use Consol’s synchronous wheel, so as to avoid that the steel belt and the belt wheel designed by the user do not coincide with each other, which can not jam or abnormal noise occurs in the process of operation, operation accuracy is poor, etc.

Steel belt with attachments

With the steel belt as the carrier, various components and devices can be added to the steel belt to meet more functional requirements.At present, in the pharmaceutical, food, electronic components automatic packaging production line and the continuous assembly line, the use of the steel belt above are loaded with various forms of accessories, some is to stop the filling, some is to locate the assembly, all the components must meet the bending operation conditions and tensile limits of the steel belt.The steel belt can not only run independently, but also be used in multiple combinations (multi-row parallel, interleaving) to meet its requirements.

Plating steel belt

CONSOL coatings are based on circular and open-end finished steel bands and are coated on their surfaces according to their conditions of use. The techniques available include TEFLON thermal plating, titanium plating, and high-heat spray thermal insulation coatings.The purpose of coating the surface of the steel belt: the surface of the steel belt anti-adhesion the surface of the steel belt anti-slip the surface of the steel belt heat insulation

Product Advantages

1.Exceptional Durability and Resistance

The Precision Steel belt is crafted from high-quality stainless and carbon steel, offering unmatched resistance to corrosion, heat, and abrasion. This ensures longevity and reliability in demanding industrial conveyor belt systems, reducing maintenance costs and extending the lifespan of your equipment.

2.Enhanced Production Efficiency

Designed to maximize throughput, the Precision Steel belt minimizes downtime in production lines across various sectors, including chemical, food, and precision machinery. Its robust construction makes it an ideal choice for industries seeking efficient metal conveyor belt solutions that enhance operational productivity.

3.Precision and Seamless Integration

Featuring meticulously designed positioning holes, the Precision Steel belt ensures seamless integration into any industrial conveyor belt systems. Its compatibility with Consol's synchronous wheels reduces misalignment and operational noise, guaranteeing smooth and accurate operation for high-precision industries.

4.Versatile and Customizable Design

The Precision Steel belt is adaptable to a wide range of applications, from pharmaceutical packaging to electronic assembly lines. Its surface can be customized with coatings like TEFLON or titanium plating, providing anti-adhesion, anti-slip, and heat insulation properties, making it a versatile metal conveyor belt component.

5.Future-Proof Investment

With its scalable design, the Precision Steel belt is a future-ready investment, capable of evolving with the growing demands of modern industries. Its ability to accommodate various attachments and devices ensures it meets diverse functional requirements, solidifying its role in advanced industrial conveyor belt systems.

About CONSOL

Industry Positioning

CONSOL is a leading international enterprise specializing in steel belts and steel belt driving systems, providing reliable solutions to customers worldwide.

Core Manufacturing Capabilities and Quality Assurance

Product Range: We offer a diverse array of steel belts, including carbon steel belts, stainless steel belts, perforated steel belts, super mirror steel belts, precision steel belts, and martensitic stainless steel belts.

Application Areas: Our products are utilized across various industries such as oil & gas, chemical, food, precision machinery, film casting, woodworking, and composite industries.

Quality Commitment: We adhere to stringent quality standards to ensure our products meet the highest industry requirements.

Production Strength

Located in Guangzhou, the heart of the Pearl River Delta, CONSOL has established a robust manufacturing base, enabling us to serve clients efficiently across the globe.

Sustainability Measures

Our steel belts are designed for durability and recyclability, contributing to sustainable industrial practices.

Customer Collaboration Process

We have built a comprehensive sales and after-sales service system, coordinating installation services near our clients' facilities to ensure optimal service quality.

Global Service Capability

Over the past decade, CONSOL has exported products to more than 30 countries, including the USA, Russia, Canada, Korea, South Africa, Iran, Turkey, Ukraine, Saudi Arabia, Spain, Holland, Brazil, Malaysia, Thailand, India, Pakistan, the Philippines, Indonesia, and Vietnam.

FAQ

Who are we?

CONSOL is an international enterprise focusing on steel belts and steel belt driving systems, committed to providing reliable solutions to customers worldwide.

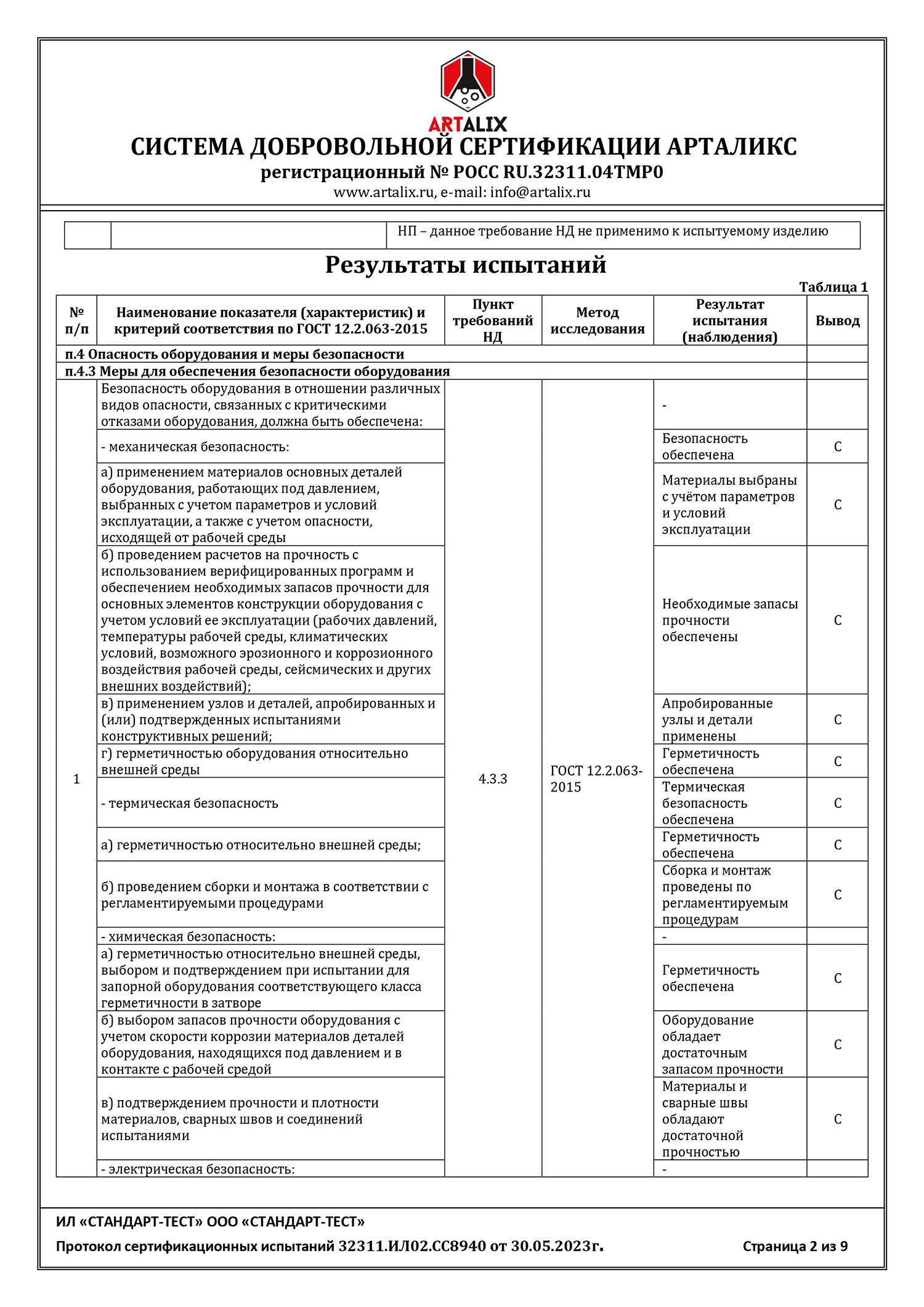

How can we guarantee quality?

We adhere to strict quality control processes and hold certifications such as SGS, CE, and ISO 9001 to ensure our products meet international standards.

What can you buy from us?

Our product offerings include various types of steel belts and conveyor systems suitable for multiple industrial applications.

Why should you buy from us and not from other suppliers?

With a decade of experience exporting to over 30 countries and a commitment to quality and customer service, CONSOL stands out as a reliable partner for your industrial needs.

What services can we provide?

We offer comprehensive services, including after-sales support, seamless welding technology, edge shaping, conveyor system rebuilding, and V-rope sticking, ensuring our clients receive end-to-end solutions.

OUR CAPABILITY

CONSOL is an international enterprise focusing on steel belt and steel belt driving system.

Related Products