Contact Us

E-mail info2@consolbelts.com

Phone/WhatsApp/Wechat

+86 18820135908

Aluminum sulfate solidification

Aluminum sulfate solidification

Транспортная система

Aluminum sulfate solidification

Aluminum sulfate solidification is an exceptional process designed to produce solid aluminum sulfate crystals for various industrial applications. With its advanced technology and efficient production capabilities, this process ensures high and reliable aluminum sulfate products.

The aluminum sulfate solidification process begins with the dissolution of aluminum sulfate in water. The liquid solution is then transformed into solid crystals utilizing state-of-the-art solidification equipment. These solid crystals have a defined shape, size, and purity, making them ideal for a wide range of industries.

One of the exceptional features of aluminum sulfate solidification is its ability to provide precise control over the crystal formation process. This allows for the production of crystals with specific properties and characteristics tailored to the requirements of different applications. The solidification process ensures uniform crystal size and distribution, resulting in consistent product quality.

The aluminum sulfate crystals find extensive use in industries such as water treatment, paper manufacturing, and tanning In water treatment, aluminum sulfate is commonly used as a coagulant to and purify water, effectively removing impurities and suspended particles. In the paper industry, it is employed as a sizing agent to improve the strength and printability of paper products. In tanning, aluminum sulfate is utilized in the process of preparing hides for leather production.

One of the unique selling points of aluminum sulfate solidification is its efficiency and reliability in production. The process ensures high productivity and consistency reducing downtime and enhancing operational efficiency. Additionally, the solidified crystals have excellent stability and storage characteristics, ensuring shelf life and ease of handling.

By utilizing aluminum sulfate solidification, industries can benefit from a reliable and high-quality source of aluminum sulfate crystals. These crystals provide exceptional performance in various applications, enhancing processes and delivering superior results. Choose aluminum sulfate solidification for your industrial needs and optimize your operations with reliable and efficient aluminum sulfate products.

In summary, aluminum sulfate solidification is a-of-the-art process that produces high-quality solid of aluminum sulfate. With its precise control, efficient production, versatile applications, this process offers an exceptional solution for industries requiring aluminum sulfate. Unlock the potential of solid aluminum sulfate crystals and elevate your industrial processes to new heights of efficiency and performance.

Precision Solidification with Advanced Flaker Technology

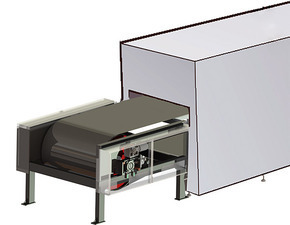

The CONSOL Aluminum Sulfate Solidification system is a precision-engineered flaker machine designed for transforming molten aluminum sulfate into dry, uniform flakes. This system supports high-throughput operations, delivering reliable flaking performance essential in modern industrial cooling solutions.

Rapid Cooling for Increased Efficiency

Featuring an efficient indirect water spray cooling system beneath the moving stainless steel belt, this flaker machine offers rapid solidification of molten materials. It’s ideal for manufacturers looking to boost efficiency with sustainable industrial cooling solutions that minimize water and energy use.

Reliable Performance in Harsh Environments

Built to operate in corrosive chemical processing environments, the flaker machine utilizes acid-resistant stainless steel and industrial-grade components. This ensures dependable operation in demanding industrial cooling solutions setups, especially for aluminum sulfate production.

Customizable for Production Demands

This flaking system is flexible enough to meet varying production capacities and cooling requirements, making it a preferred solution for chemical manufacturers seeking customizable industrial cooling solutions based on consistent flake size and low maintenance costs.

Product Advantages

- Efficient Flaking Process: The flaker machine consistently produces uniform flakes, ideal for packaging and downstream chemical processing.

- Closed-Loop Cooling Efficiency: As part of CONSOL’s industrial cooling solutions, it saves water while ensuring non-contaminated, high-quality output.

- Material Durability: Resistant to chemical corrosion, this flaker machine is purpose-built for aluminum sulfate and other aggressive materials.

- User-Friendly Operation: Designed with industrial users in mind, the control system enhances ease of use within your industrial cooling solutions framework.

- Scalable System: The modular setup allows this flaker machine to scale from small batch applications to full industrial-scale production.

About CONSOL

Industry Positioning

CONSOL is a leading international enterprise specializing in steel belts and steel belt driving systems, providing reliable solutions to customers worldwide.

Core Manufacturing Capabilities and Quality Assurance

Product Range: We offer a diverse array of steel belts, including carbon steel belts, stainless steel belts, perforated steel belts, super mirror steel belts, precision steel belts, and martensitic stainless steel belts.

Application Areas: Our products are utilized across various industries such as oil & gas, chemical, food, precision machinery, film casting, woodworking, and composite industries.

Quality Commitment: We adhere to stringent quality standards to ensure our products meet the highest industry requirements.

Production Strength

Located in Guangzhou, the heart of the Pearl River Delta, CONSOL has established a robust manufacturing base, enabling us to serve clients efficiently across the globe.

Sustainability Measures

Our steel belts are designed for durability and recyclability, contributing to sustainable industrial practices.

Customer Collaboration Process

We have built a comprehensive sales and after-sales service system, coordinating installation services near our clients' facilities to ensure optimal service quality.

Global Service Capability

Over the past decade, CONSOL has exported products to more than 30 countries, including the USA, Russia, Canada, Korea, South Africa, Iran, Turkey, Ukraine, Saudi Arabia, Spain, Holland, Brazil, Malaysia, Thailand, India, Pakistan, the Philippines, Indonesia, and Vietnam.

FAQ

Can the CONSOL flaker machine be customized for different production scales?

Yes, the CONSOL aluminum sulfate solidification flaker machine features a modular and scalable design, allowing adjustments in throughput and flake size to meet varying production demands across pilot runs and full-scale operations.

What materials ensure the flaker machine’s durability in corrosive environments?

The machine is constructed using acid-resistant stainless steel and industrial-grade components. This design protects the steel belt flaker from corrosion, ensuring long-term reliability in harsh chemical processing conditions.

How is the steel belt cooling system implemented in the flaker machine?

The device uses an indirect water spray cooling method underneath a moving stainless steel belt, providing rapid solidification and water conservation through a closed-loop system within the steel belt cooler setup.

What installation and maintenance support does CONSOL provide?

CONSOL offers coordinated installation services near customer facilities, ensuring proper setup of the flaker machine and related systems. Regular maintenance focuses on acid-resistant parts and belt integrity to sustain consistent flake quality and uptime.

OUR CAPABILITY

CONSOL is an international enterprise focusing on steel belt and steel belt driving system.

Related Products