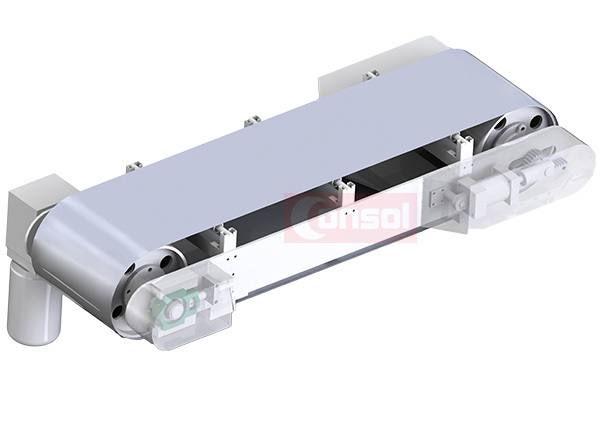

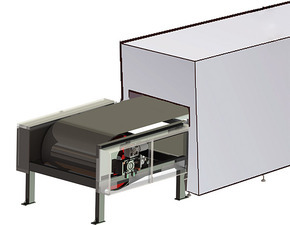

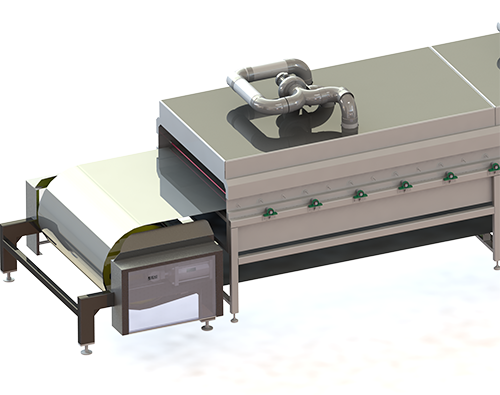

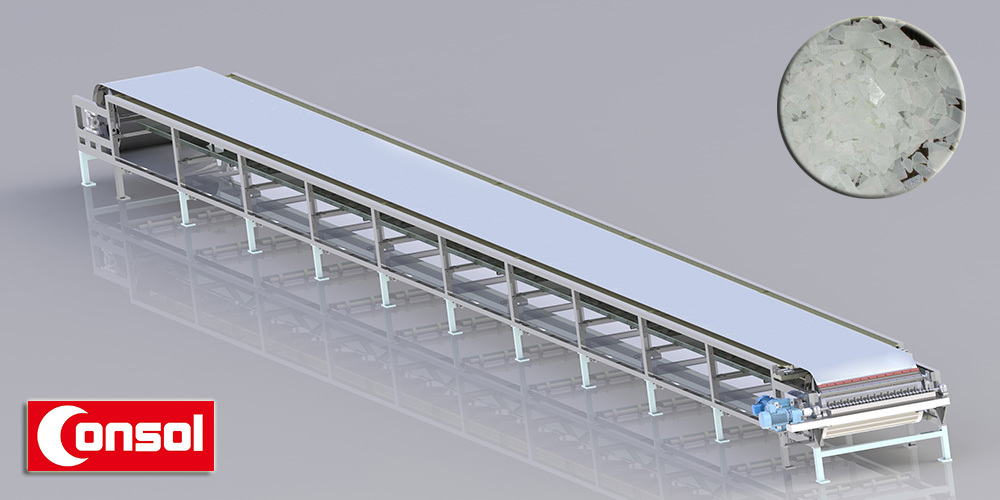

Single belt flaker

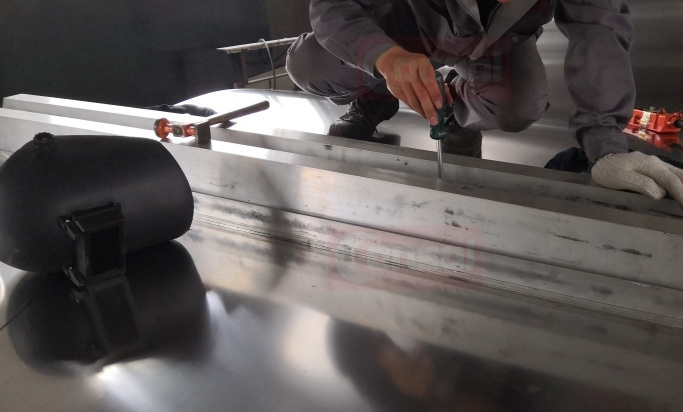

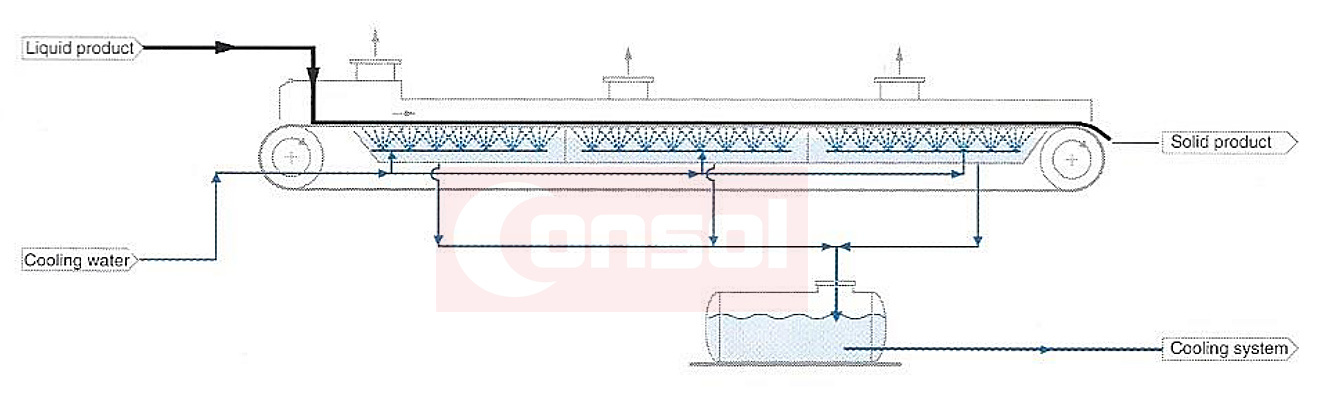

Steel belt flaker working principle

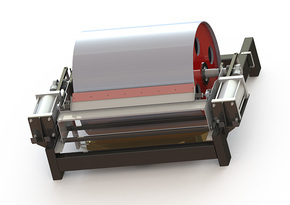

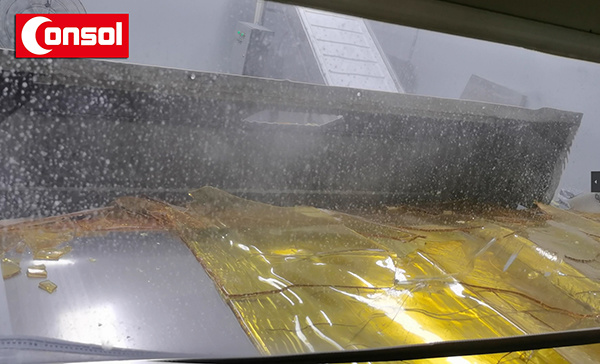

The melting material go through the overflow gate distributor or rolling distributor and spread on the steel belt which is moving at a constant speed, there are continuous spraying and cooling units set under the steel belt, to ensure the material in the steel belt can be solidified quickly, and get the final flake production. After the cooling system,the flakes will be broken into small pieces by breaker and go to the next packing processing.

Application

the steel belt flaker is suitable for all kinds of materials with melting point (softening point) at 250℃ to condense for flaking, typical application materials are resin, asphalt, stearic acid products, hot sol, m-phenylene diamine, urea, rubber and plastic additives.

Main advantages

·Reduce dust and improve operating environment;

·Continuous operation to improve production efficiency.

·Thin steel strip heat transfer and forced spray cooling, so that hot melt materials can be quickly solidified.

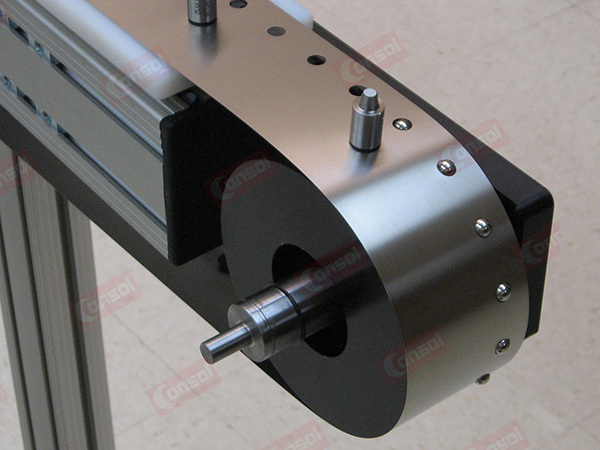

·The steel belt and the distributor adopt frequency conversion to adjust the speed, which can be adjusted and controlled conveniently according to the production capacity and physical property.

·The system operation is stable and reliable.

Based on the CONSOL steel belt, the cooling system is versatile and can be adapted to meet the needs of specific applications.

Steelbelt can be adapted to meet the needs of specific applications such as product thickness temperature profile or processing times.

Suitable for all kinds of resin rosin like Hydrocarbon resin, Phenolic resins, Epoxy resins, Ink resins, Gum resins...

Double belt flaker is a steel belt cooling system with advantages of small space occupation but large capacity,high efficiency and strong practicality.

CONVEY SYSTEM

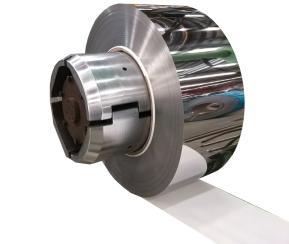

STEEL BELT

Copyright © 2023 Guangzhou Consol Machinery Equipment Co., Ltd. | All Rights Reserved. 粤ICP备18032917号 SEO Powered by:www.300.cn