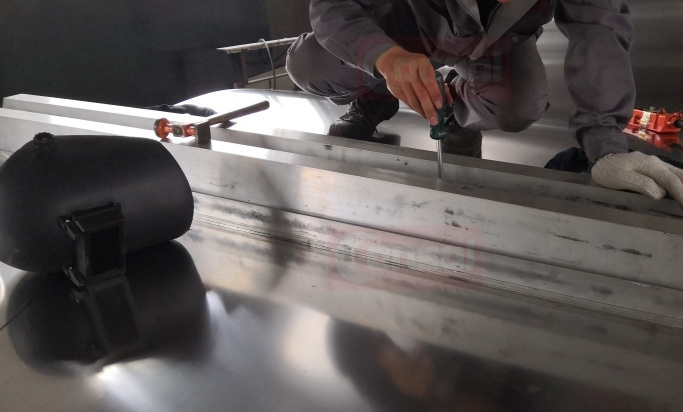

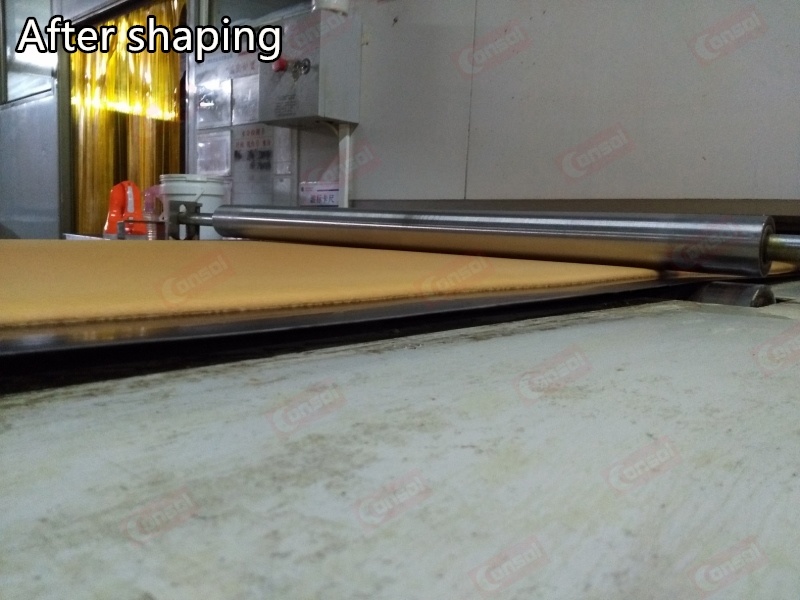

Edge shaping

NEWS&EVENT

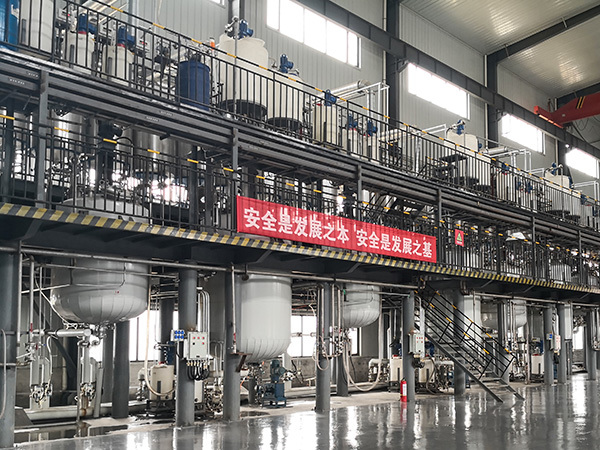

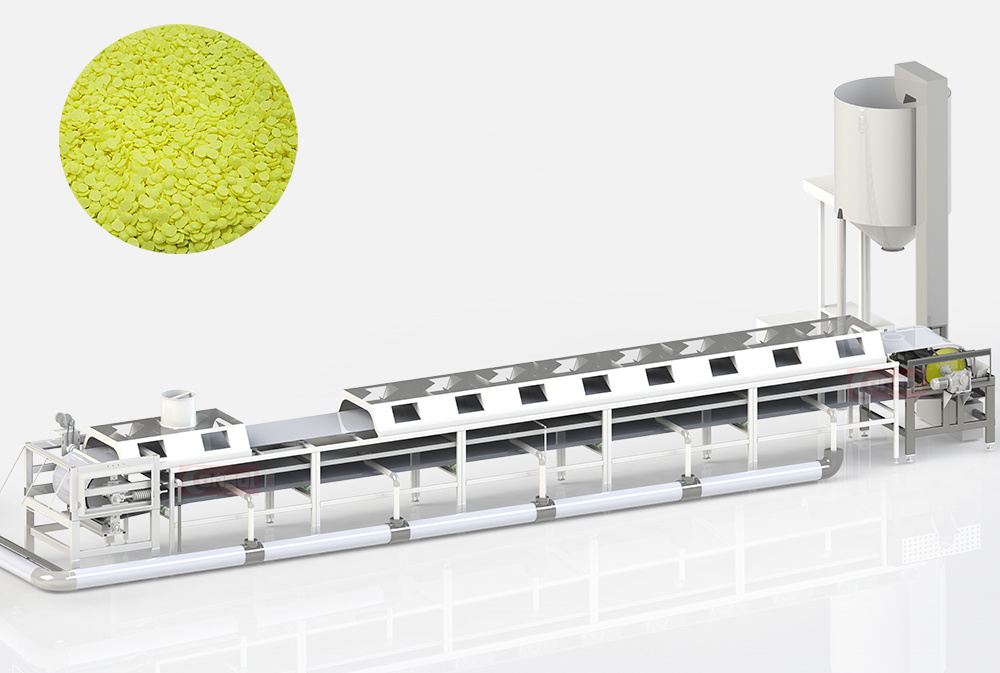

Steel belt pastillator granulation production line for jewelry wax middle temperature wax

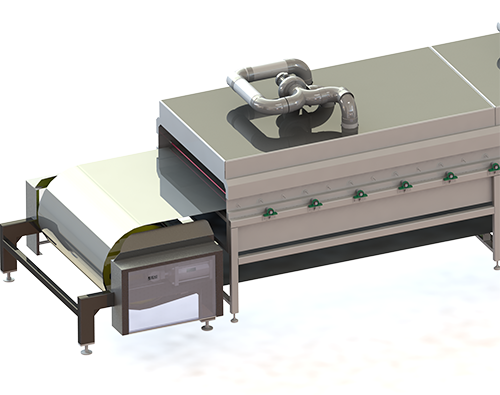

Kenschau successfully installed an ultra-wide sheet production line in Europe

South Africa, Israel customers to visit our company, and discuss related business

Boosting Efficiency in Plastic Granulation: The Sulphur Advantage

Optimizing Cooling Processes: Steel Belt Coolers for Steel Materials

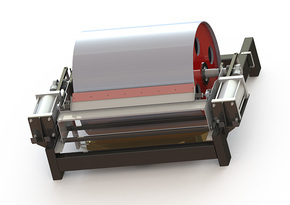

Steel Belt Cooler: A Crucial Component in the Steel Materials Industry

The Ultimate Guide to Choosing the Right Conveyor System

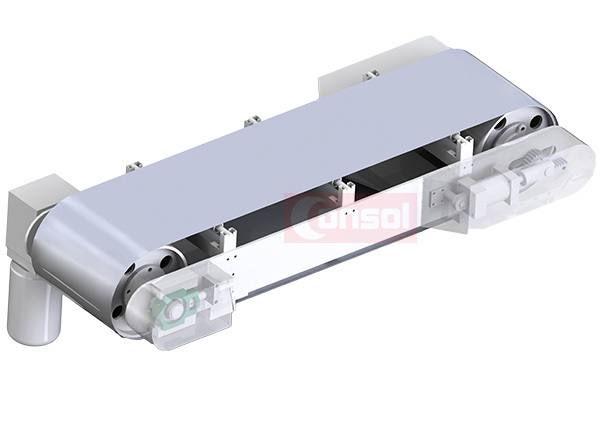

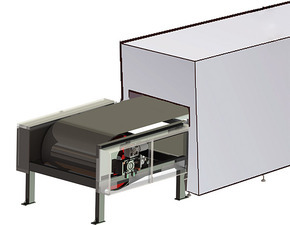

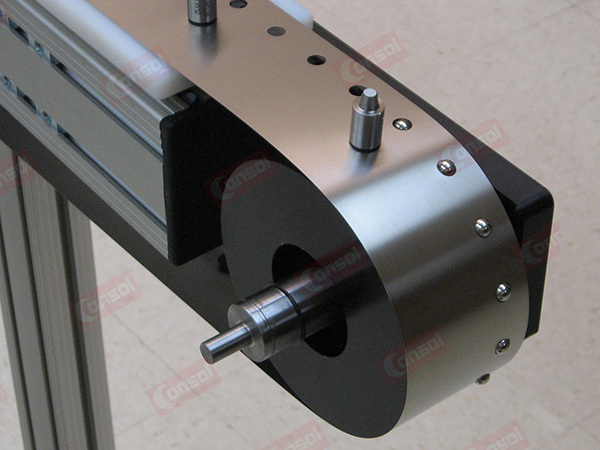

CONVEY SYSTEM

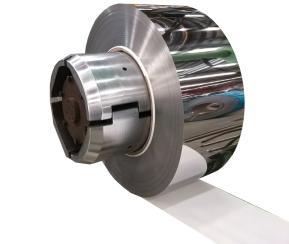

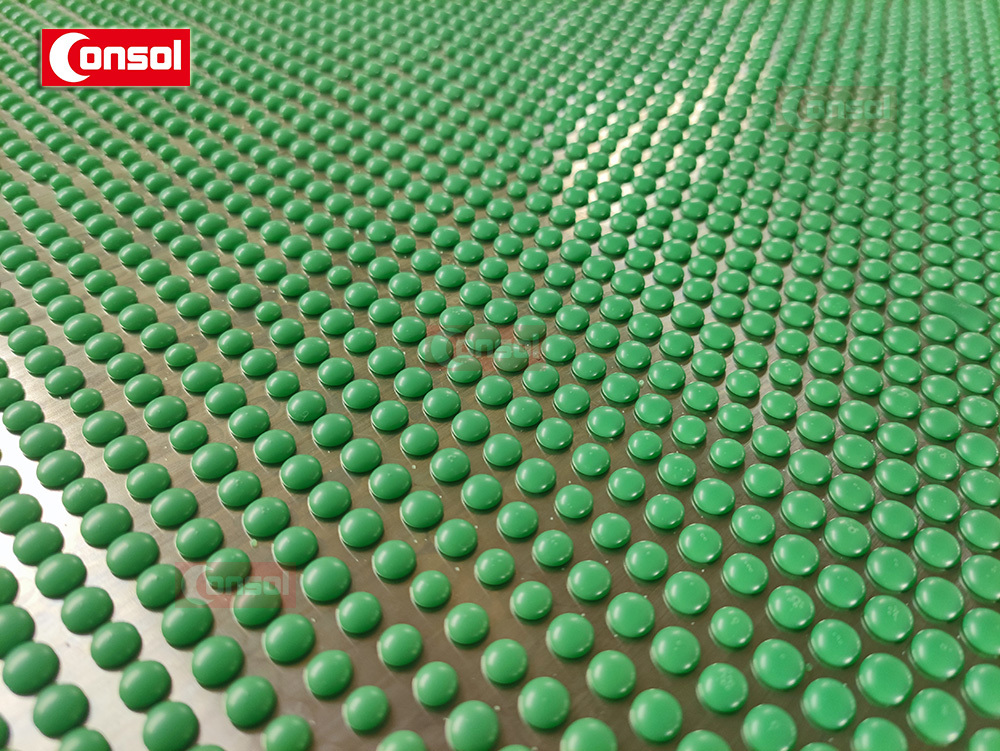

STEEL BELT

Copyright © 2023 Guangzhou Consol Machinery Equipment Co., Ltd. | All Rights Reserved. 粤ICP备18032917号 SEO Powered by:www.300.cn