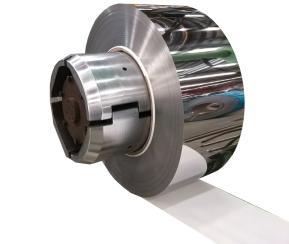

Stainless steel belt

Characteristic of stainless steel belt AS1200

·High strength and hardness

·Easy to clean,no bacterial residue

·High temperature resistance and corrosion resistance

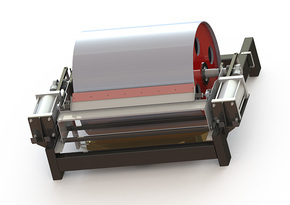

·Flat and straight, stably running

·Perfect welding technology with long service life

·Any size can be customized

·We guarantee every belt we sold.

Dynamic strength

The strength of stainless steel belt AS1200 is traditionally understood as its ability to resist flow/deformation and breakage (brittle fracture or ductile rupture) under applied load. The breakage, though looking like an abrupt occurrence, actually results from a strain-rate/time dependent process of damage evolution, 60% of the test material can bear the load cycle of 2,000,000 times. At the normal temperature environment, the fatigue limit of basic metal is + 470 N/mm squared.

Corrosion resistance

The stainless steel belt AS1200 is capable of operating normally at temperatures from -50° to 300° and exhibits a very stable operating condition.Whether it is food industry or chemical industry, stainless steel belt can adapt to the corrosive environment.Advanced welding technology enables the weld zone with up to 90% property compare with parent material.

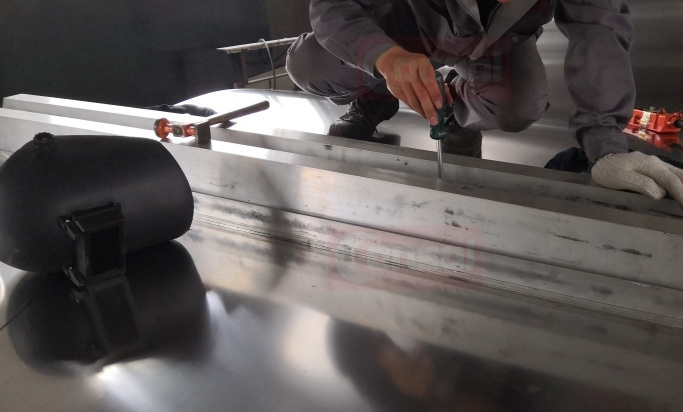

Weldability

For stainless steel belt, TIG/L/M-P is the first choise. This welding technology can control the thickness tolerance within 0.02mm. According to different welding factor of different material, welding strength can up to 80%-97% after treatment(Compare with raw material).

Scope of supply

Length:Customizable

Width:2000mm(No merging)

Thickness:0.4/0.5/0.8 / 1.0 / 1.2 mm

Austenitic stainless steel AS1200 steel belt can be used in almost all industry, such as food industry, chemical industry,rubber industry,film industry, electron industry, phaemaceutical industry and so on. Surface finish is one of the reference for different industries, mirror polished surface is also available.

Application scope

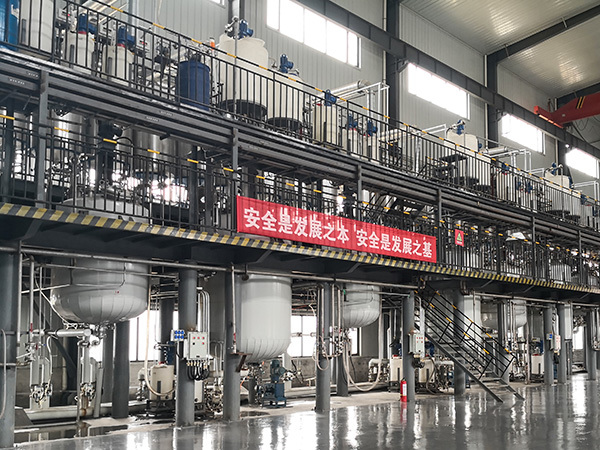

Austenitic stainless steel belt AS1200 for chemical industry.

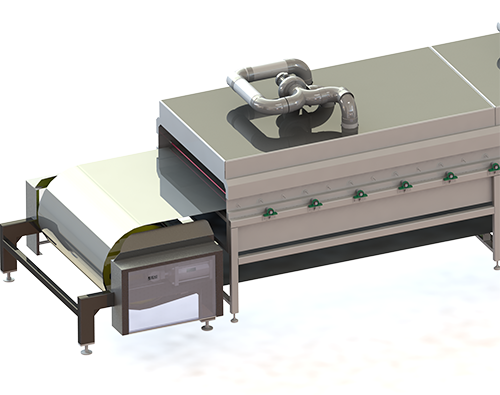

Steel belt granulator: Petroleum resin, phenolic resin, rosin resin, polyamide resin, epoxy resin, sulfur, paraffin, special wax, asphalt, stearic acid, fatty acid, chloroacetic acid, antiaging agent, hot melt adhesive, maleic anhydride, carved white block, p-nitrochlorobenzene, maleic anhydride, aluminum sulfate, calcium chloride, sodium thiocyanate, phloro-diamine, catechol.

Steel belt flaker: For Epoxy, Polyster resin, Phenolic resin, Acrylic resin, Hydrocarbon resin,and other all kinds of resin.

Powder coating, film casting, rubber vulcanization.

The application of austenitic stainless steel belt AS1200 infood industry

Up to 300°C:Steamer for cakes,sandwiches,dumplings and other food steaming; drying system for Vegetables and fruits.

Low to -50°C:Candy&chocolate granulation, seafood&fished IQF processing.

Stainless steel belt ASS1200 is very suitable for granulation for petrochemicals like sulphur, sulphur bentonite, paraffin wax, resin, pitch, urea, hot melt adhesive...

Stainless Steelbelt is the core technology in candy/chocolate granulation/ pelleting production process.

Consol AS1200 steel belt is a kind of special steel belt that can adapt to extreme environment

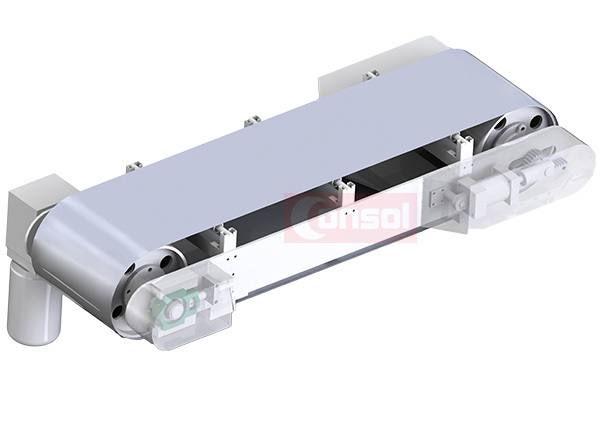

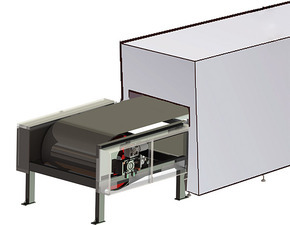

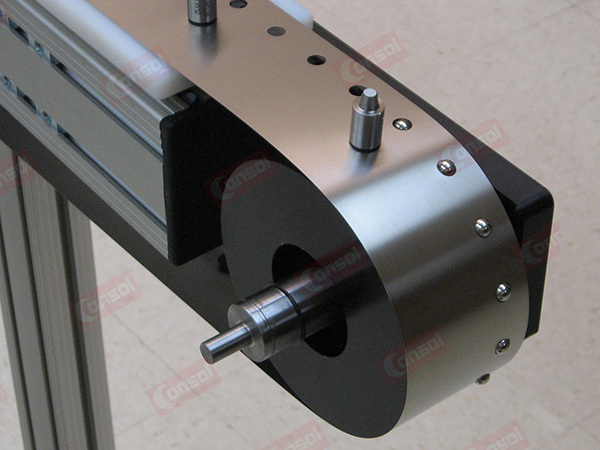

CONVEY SYSTEM

STEEL BELT

Copyright © 2023 Guangzhou Consol Machinery Equipment Co., Ltd. | All Rights Reserved. 粤ICP备18032917号 SEO Powered by:www.300.cn