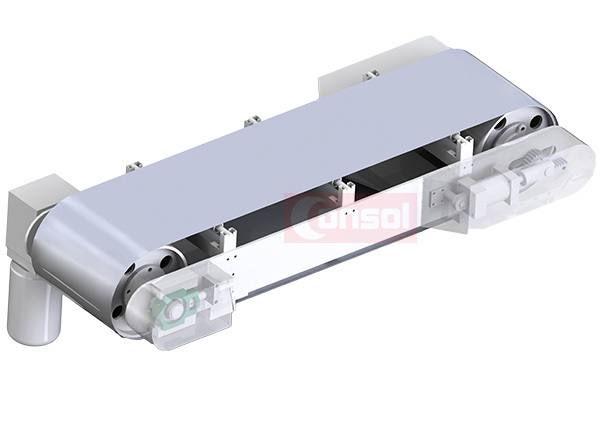

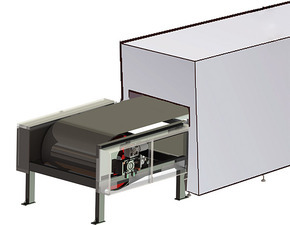

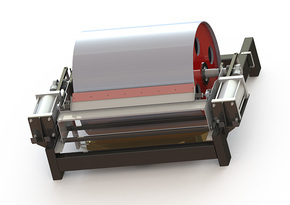

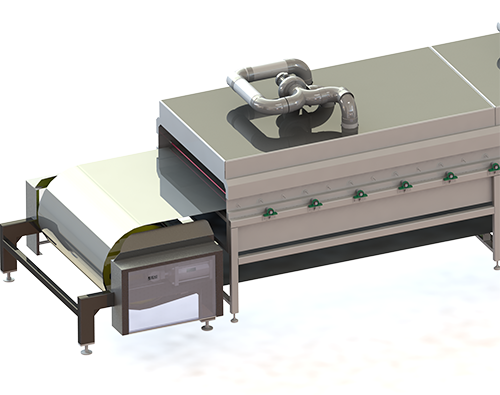

Double belt press

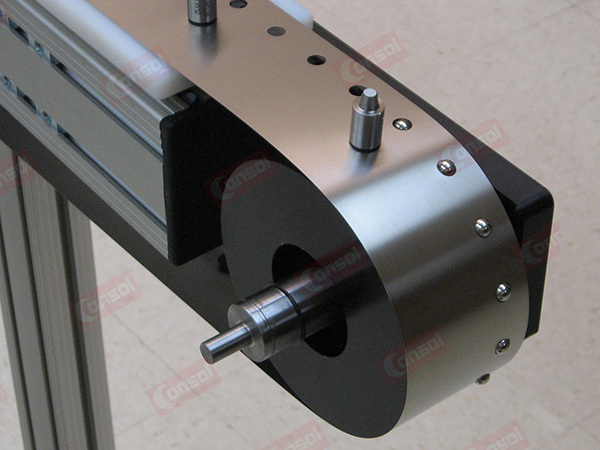

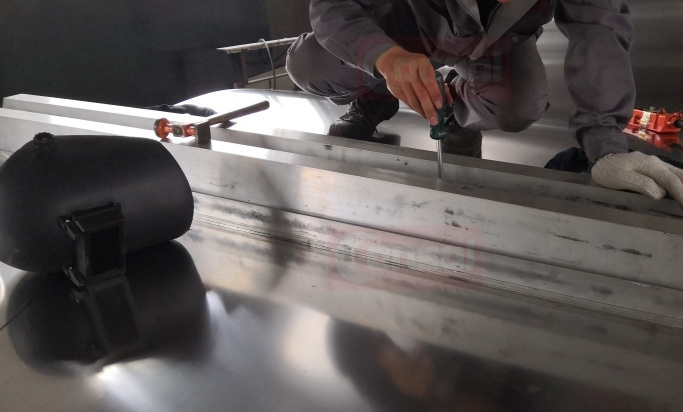

Two circulating steel belts run close to the roller (chain blanket) in the body of the press, which is composed of multiple frames of the same design, supported by high-strength steel beams.The lower hot pressing plate is fixed on the supporting surface of the frame, while the upper hot pressing plate is fixed on the supporting surface of the frame through multiple sets of oil cylinders, and can move up and down to transfer pressure and heat.The two blankets loop around the upper and lower hot plates at half the speed of the steel belt.The front and rear of the press body are connected with a set of steel belt driving and tension roller. The steel belt drives the roller (chain) to make processing on the hot press.

The pre-loaded material is fed into the press inlet with an Angle of entry by the conveyor and then driven by the steel belt into the presser. At the inlet the material is gradually compressed and a large amount of gas is extruded from the material. Because the material is heated, the temperature of the extruded gas increases and gas preheats the material.The material continues to run along with the steel belt in a rising temperature environment cause by pressure, to achieve the technological process of pressure and temperature changes that meet the needs of the hot pressing of the material are completed in the whole hot pressing area.Completed product will be conveyed out of presser by steel belt and go into the next process.

Main application

·Pure Acrylic artificial stone

·Pure Acrylic artificial stone

·Composite Acrylic artificial board

·Resin plate

·Lamination material

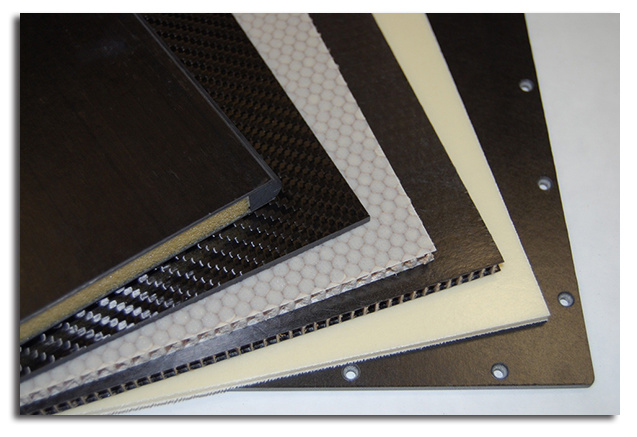

·Fibre reinforced composite material

·Honey comb plate

·Glass-fiber reinforced polypropylene

·PP, PE, PA

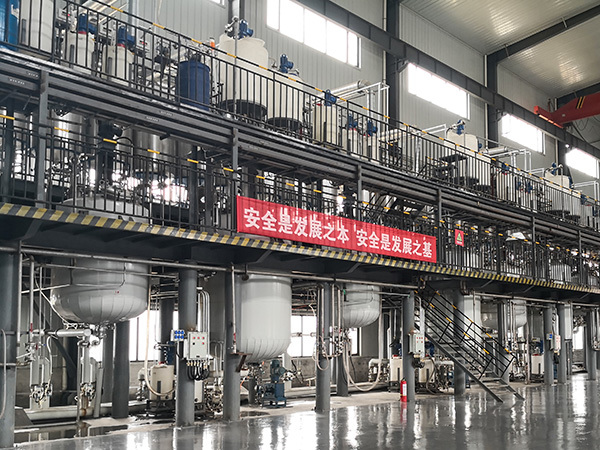

Suitable for all kinds of resin rosin like Hydrocarbon resin, Phenolic resins, Epoxy resins, Ink resins, Gum resins...

Double belt flaker is a steel belt cooling system with advantages of small space occupation but large capacity,high efficiency and strong practicality.

Water soluble film casting system is based on steel belt tunnle dryer, the wet material will be extruded from feeder and go through the steel belt tunnel oven...

CONVEY SYSTEM

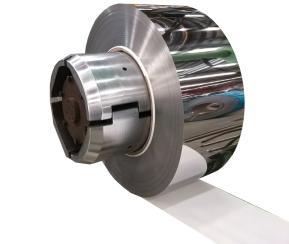

STEEL BELT

Copyright © 2023 Guangzhou Consol Machinery Equipment Co., Ltd. | All Rights Reserved. 粤ICP备18032917号 SEO Powered by:www.300.cn