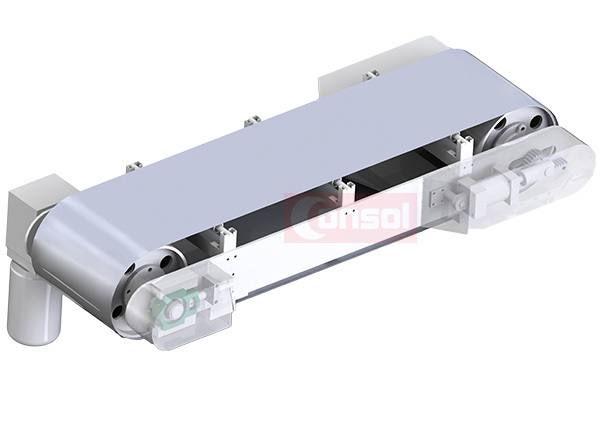

Double belt flaker

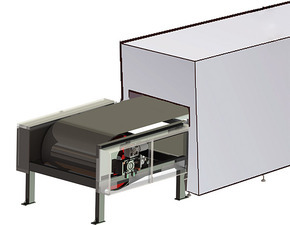

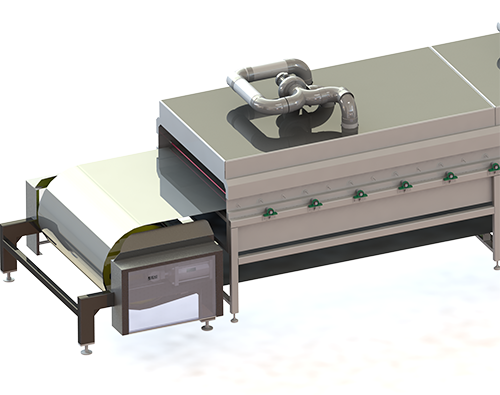

Principle of double belt flaker/cooler

Liquid material go through the heating pipe and enter into the over flow weir device and continuously cast on the surface of the steel belt. The heat of product extracted by both sides of steel belt, and good water cooling exchange, so as to achieve excellent cooling effect.

The upper steel belt of double belt flaker/cooler is cooled by spraying device, while the lower steel belt is cooled by nozzle device, thus forming a continuous and uniform cooling effect.Water from the upper steel belt is collected between the two belts and overflows to the water tray at both ends.The water from the lower steel belt is collected in the water tray and returned to the tank by gravity. Liquid material will be cooled down through the steel belt and then solidified into flakes, then broken into small pieces by two crushers.

During solidification process of double belt flaker/cooler, cooling water and liquid product will not contact directly, keep the resin liquid product from being polluted and changed itself character, cooling water can recycle use or drain.

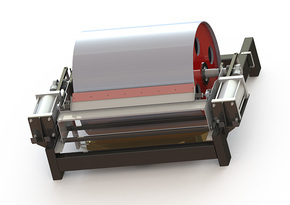

Crusher

High-speed breaker, it has a safety guard, break the material will flow through discharge device with variable speed geared motor, with chain drive and protective covering. The pin breaker is covered with a hood for safety reasons. A maintenance door is installed on the top side with window. With two variable speed geared motors, drive power approx. 5.5 kW *2, directly drived by motor, speed variation by Automation.

Control system

·Electronic control cabinet

·Protection switch

·Monitoring loop and control instrument

·Contactor

·Auto-check and emergency cut-off

·Main protection switch

·Steel belt,transducer control

·Jerk button

·Inside connection

Double belt flaker/cooler

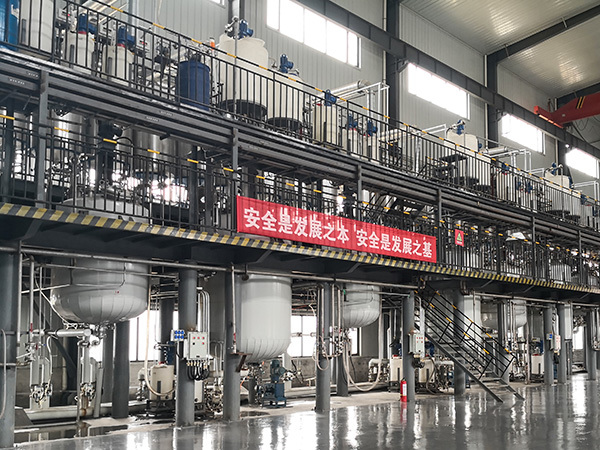

Double belt flaker is a steel belt cooling system with advantages of small space occupation but large capacity,high efficiency and strong practicality.

Suitable for all kinds of resin rosin like Hydrocarbon resin, Phenolic resins, Epoxy resins, Ink resins, Gum resins...

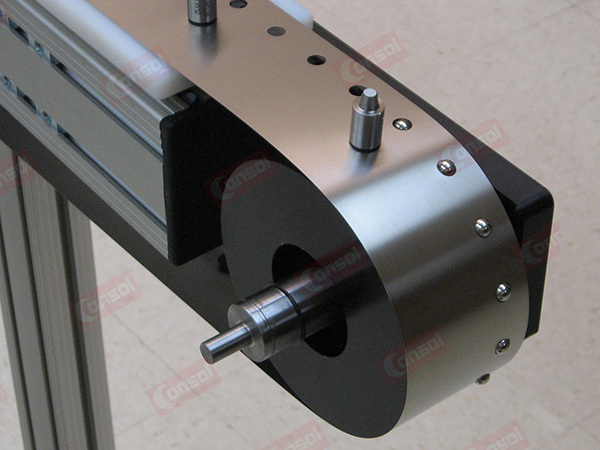

CONVEY SYSTEM

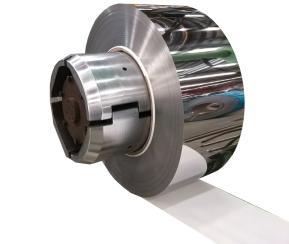

STEEL BELT

Copyright © 2023 Guangzhou Consol Machinery Equipment Co., Ltd. | All Rights Reserved. 粤ICP备18032917号 SEO Powered by:www.300.cn