Conveyor System Rebuild

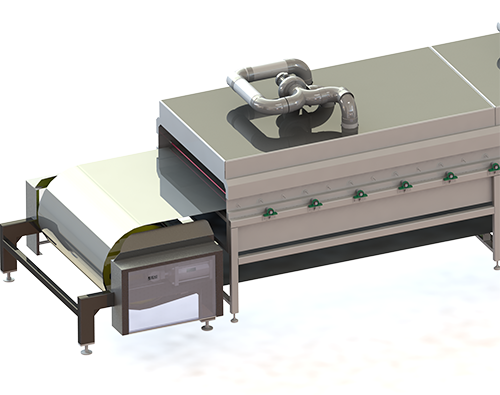

Do not need to buy the new equipment but can produce the new products!

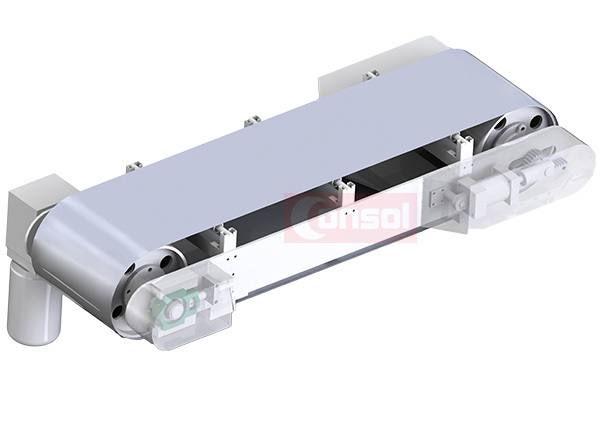

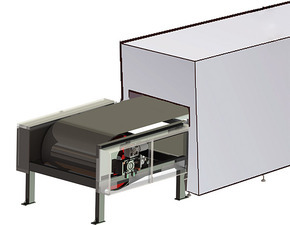

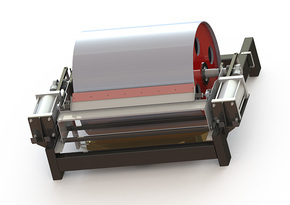

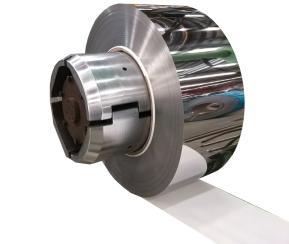

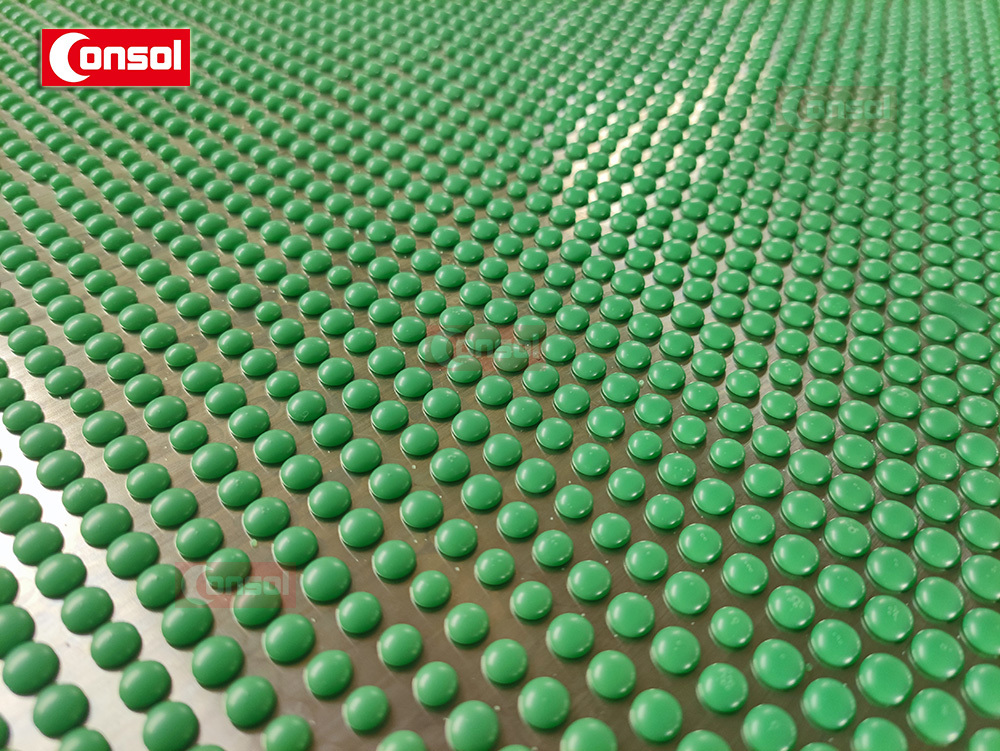

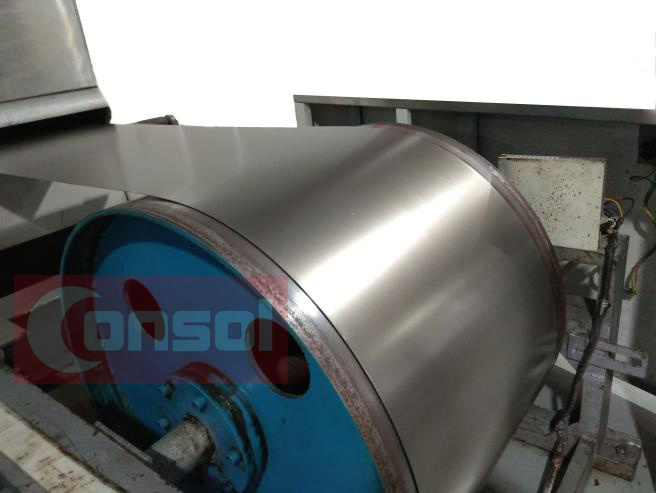

Traditional oven uses the wire-mesh as convey belt, but it has lots of defects due to the lack of its own property, such as short serving life, high vibration, large stretching, difficult to clean, limitation of product and so on. lf replace with steel belt it is very easy to solve the problems above.

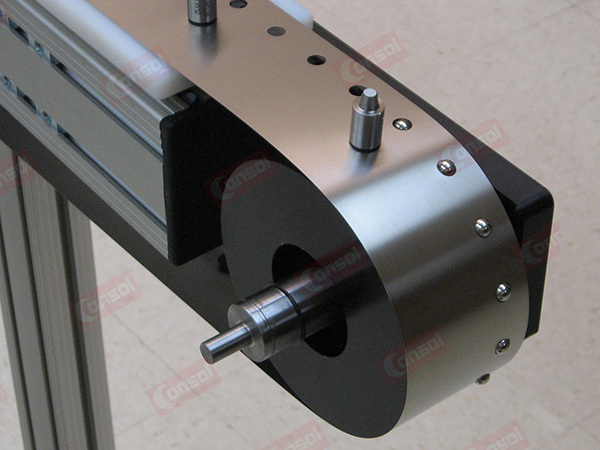

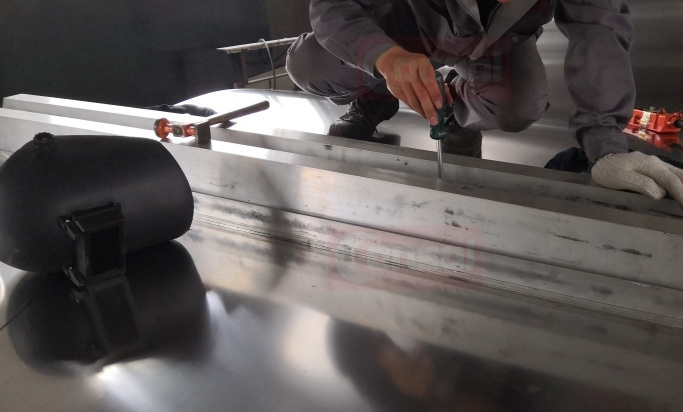

Different in weight tension force, thermal conductivity and so on, it is necessary to transform the system spares after replacing steel belt, otherwise, it could be a series problems like belt run off, drum skid, even cause belt deform and crack.

Aim at oven upgrade, we have an experienced engineer team, which can do well these stuff with less time and cost, remove all the troubles caused by lack of technology.

NEWS&EVENT

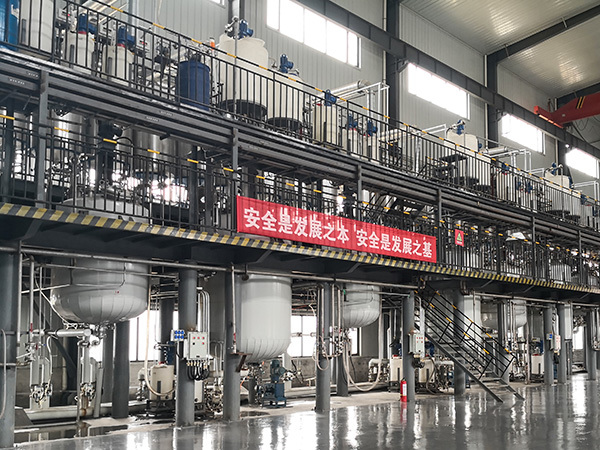

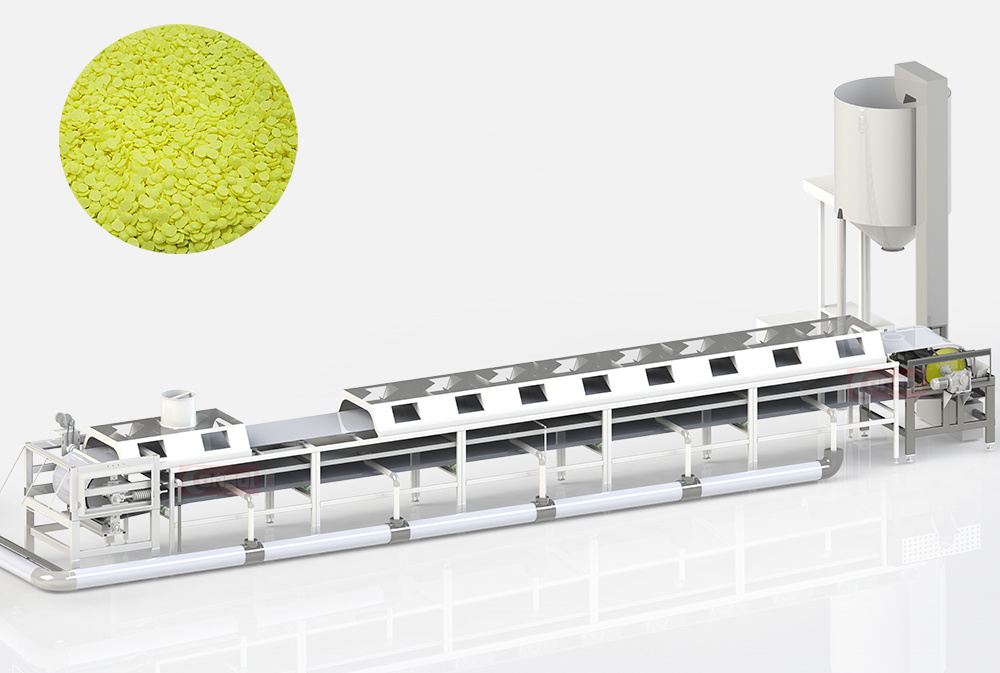

Steel belt pastillator granulation production line for jewelry wax middle temperature wax

Kenschau successfully installed an ultra-wide sheet production line in Europe

South Africa, Israel customers to visit our company, and discuss related business

Boosting Efficiency in Plastic Granulation: The Sulphur Advantage

Optimizing Cooling Processes: Steel Belt Coolers for Steel Materials

Steel Belt Cooler: A Crucial Component in the Steel Materials Industry

The Ultimate Guide to Choosing the Right Conveyor System

CONVEY SYSTEM

STEEL BELT

Copyright © 2023 Guangzhou Consol Machinery Equipment Co., Ltd. | All Rights Reserved. 粤ICP备18032917号 SEO Powered by:www.300.cn