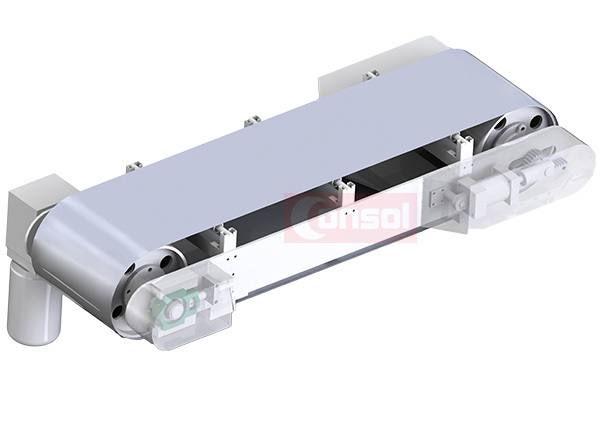

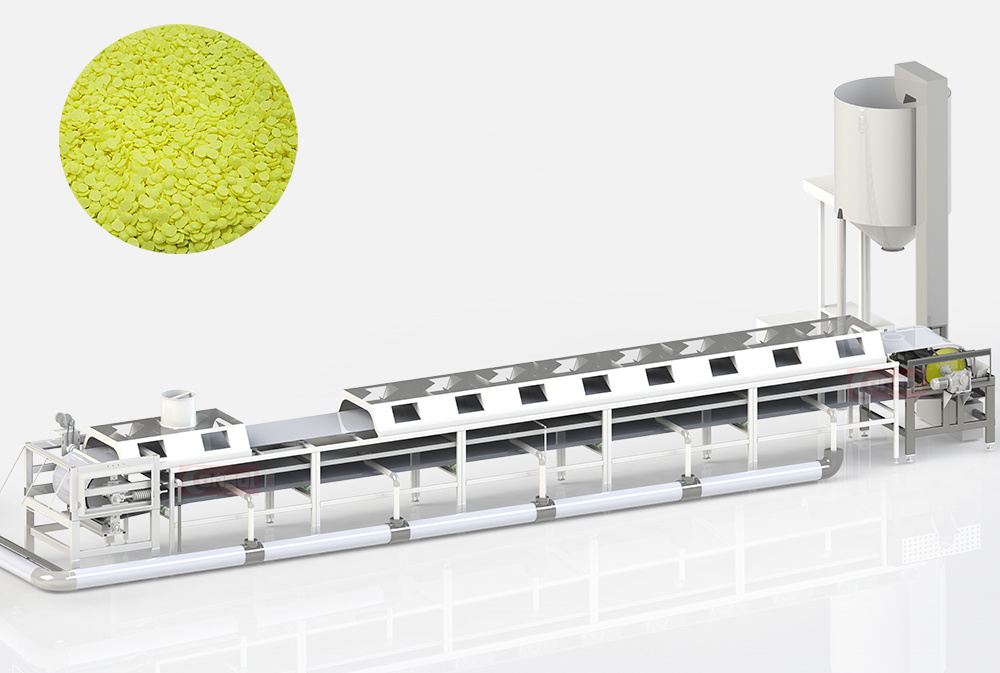

Granulator-Pastillator

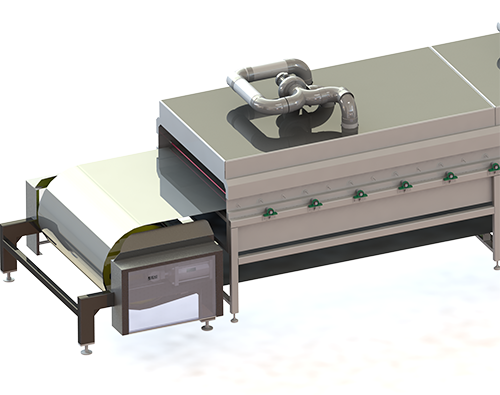

Rotary belt condensation pastillator granulator&pelletizer is using low melting point characteristic of the material (50 ℃ to 300 ℃), through the feeding head, the liquid material will drop into the upstream moving steel belt,with the continuous spray cooling device set at the bottom of the steel belt (spray type water cooling), materials will be cooled quickly and become solidification in the process of conveying. According to the different material properties and purpose, it can be chose continuous drip, straight and full width fabric approaches such as overflow, to get products with shapes of half globular, strip and sheet.

Main features of pastillator granulator&pelletizer

1.Adopts high strength thin steel belt, so that the material can be rapidly cooled and solidified into pastilles. Because of the reversing bend of steel belt at the unloading end, steel belt and solidified material can be separated easily, so that achieve the granulation without damage, no dust, no sewage, good production environment.

2.Adopts double frequency conversion speed adjustment of distributor and steel belt, which can be adjusted and controlled according to the production capacity and physical parameters. The pastillator granulator&pelletizer has high level of automation and can be operation by only 1 person, or fully enclosed with unmanned operation.

3. The application range is wide, the melting point (softening point) within 300℃ can be granulated, toxic materials can be producing in a sealed environment.

4. Product size is uniform, regular and beautiful., granulation rate ≥98%, particle size can be selected between 3-12mm, product shape has pellet, strip and sheet.

5. Through the installation of the automatic tracking system, the steel belt can run smoothly in the long continuous operation of the equipment, stable,on out of tracking, non slipping, effectively extending the service life of the steel belt.

Application of pastillator granulator&pelletizer

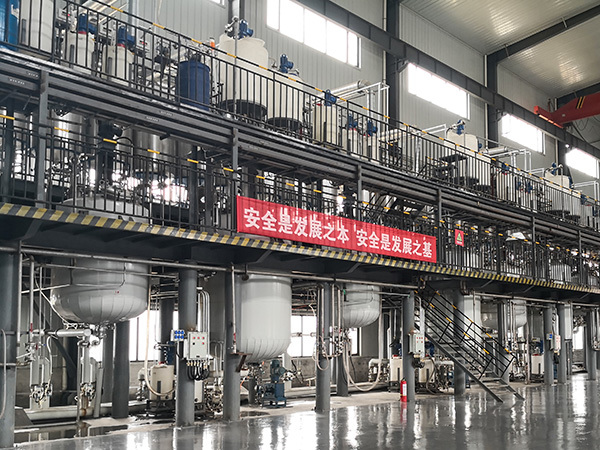

This pastillator granulator&pelletizer system is suitable for material with melting point (softening point) within 300 ℃ , supercooling crystallization solidification of all materials, such as sulphur bentonite, petroleum resin, phenolic resin, rosin resin, polyamide resin, epoxy resin, sulfur, paraffin, special wax, bitumen, stearic acid, fatty acid, chloroacetic acid, antiager, hot melt adhesive, maleic anhydride, carved white block, on the nitro benzene chloride, partial anhydride, aluminum sulfate, calcium chloride, sodium cyanide, sulfur m-phenylene diamine, catechol, all kinds of rubber auxiliaries are suitable for this equipment.

Sulphur granulation system refers to pastillator machine for sulphur,this kind of machine is one of steel belt cooler.

Suitable for all kinds of resin rosin like Hydrocarbon resin, Phenolic resins, Epoxy resins, Ink resins, Gum resins...

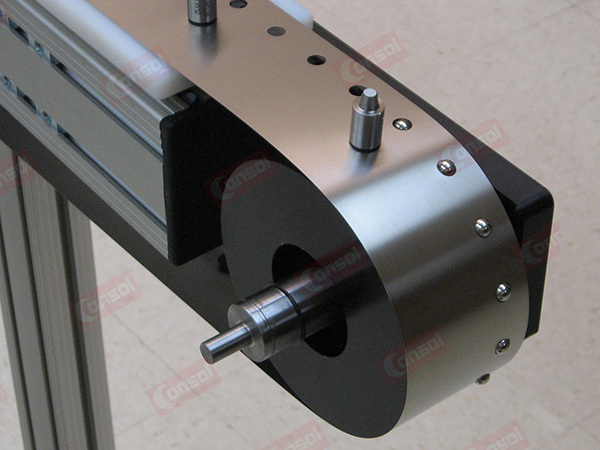

Based on the CONSOL steel belt, the cooling system is versatile and can be adapted to meet the needs of specific applications.

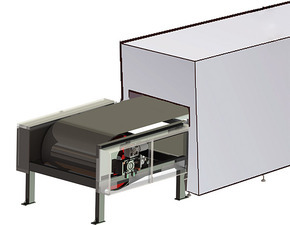

CONVEY SYSTEM

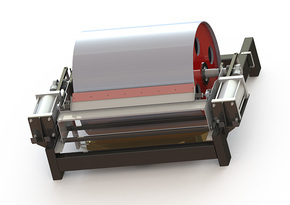

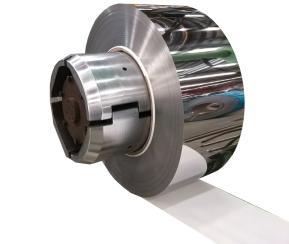

STEEL BELT

Copyright © 2023 Guangzhou Consol Machinery Equipment Co., Ltd. | All Rights Reserved. 粤ICP备18032917号 SEO Powered by:www.300.cn