Sulphur Granulation Techniques and Machinery: A Comprehensive Overview

2024-04-15

In the realm of manufacturing processing machinery, sulphur granulation plays a crucial role in various industries, especially in the production of fertilizers, pesticides, and chemicals. The process involves converting liquid sulphur into solid granules for easier handling and transportation. In this comprehensive overview, we will delve into the different techniques and machinery used in sulphur granulation.

**Types of Sulphur Granulation Techniques**

*Prilling*

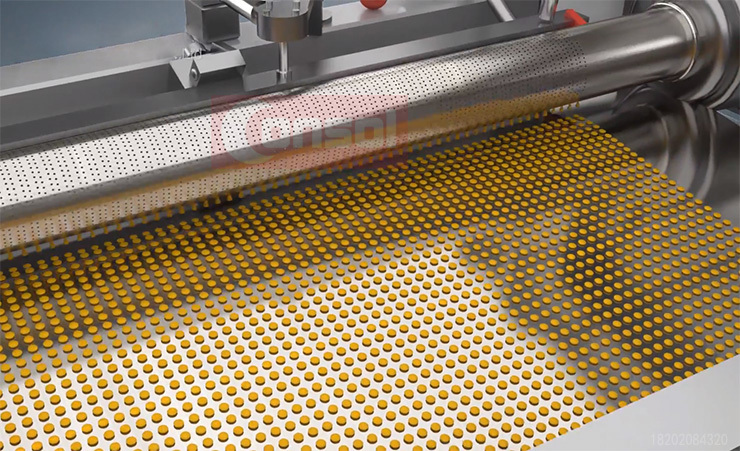

Prilling is one of the most common techniques used in sulphur granulation. It involves the use of a prilling tower where molten sulphur is sprayed through a nozzle to form droplets. These droplets solidify as they fall through the tower, forming spherical granules of varying sizes.

*Granulation Drum*

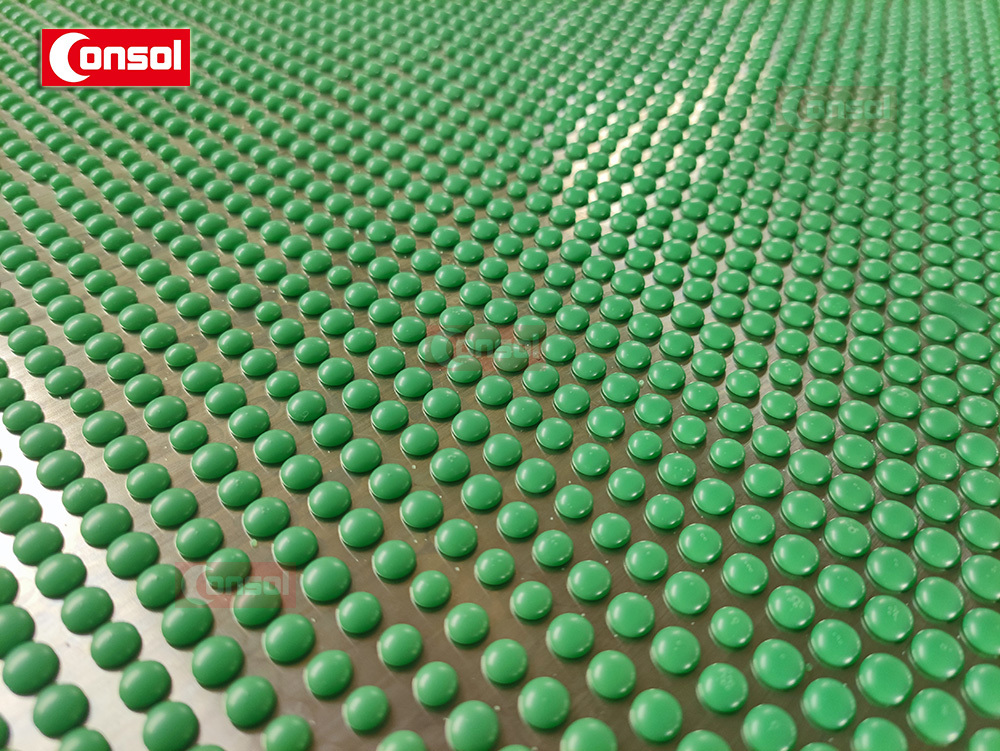

Another popular technique is granulation drum, where molten sulphur is poured into a rotating drum along with a binder material. The drum's movement helps in coating the sulphur particles with the binder, resulting in uniform and stable granules.

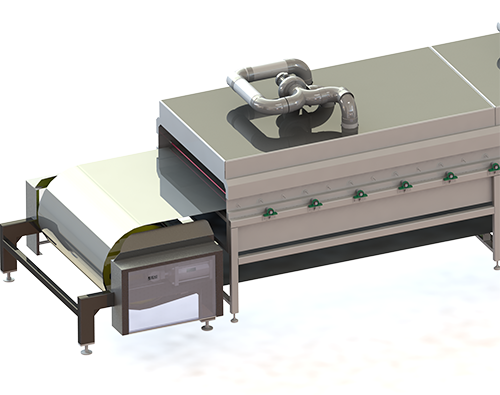

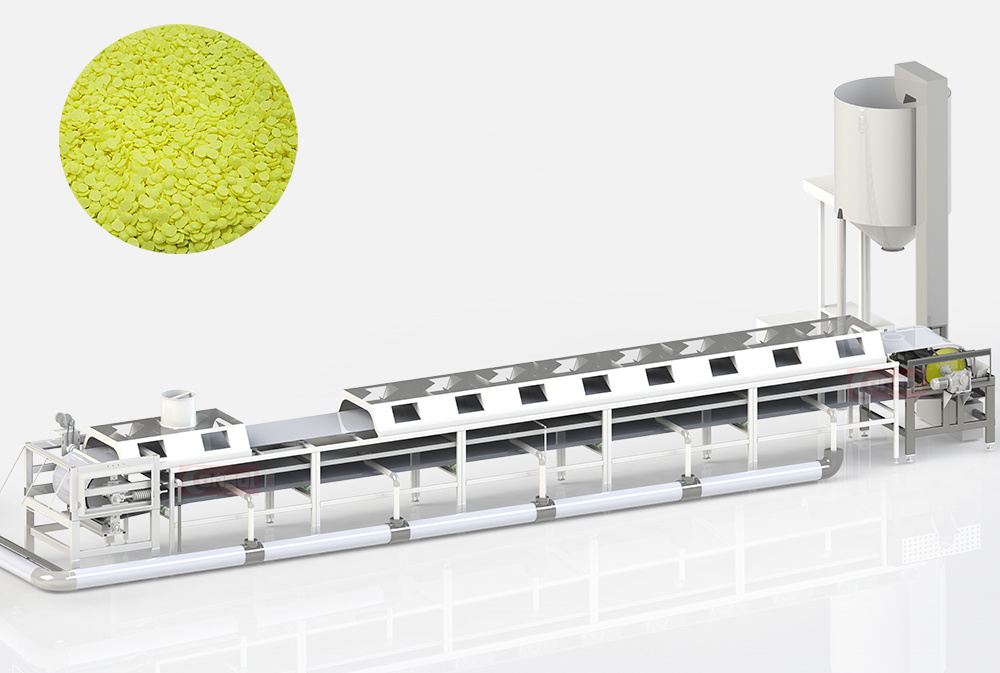

*Fluid Bed Granulation*

Fluid bed granulation utilizes a stream of hot air to fluidize and cool the molten sulphur, forming granules of desired size. This technique offers better control over the granule size and shape, making it ideal for producing high-quality sulphur granules.

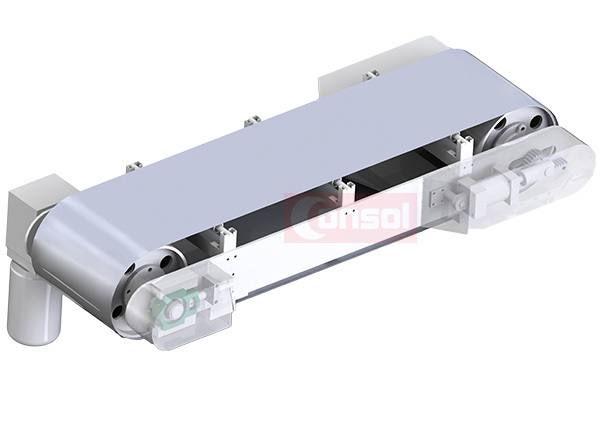

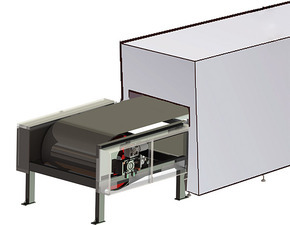

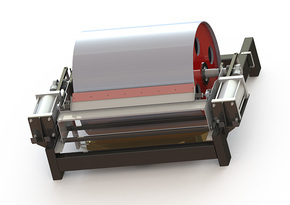

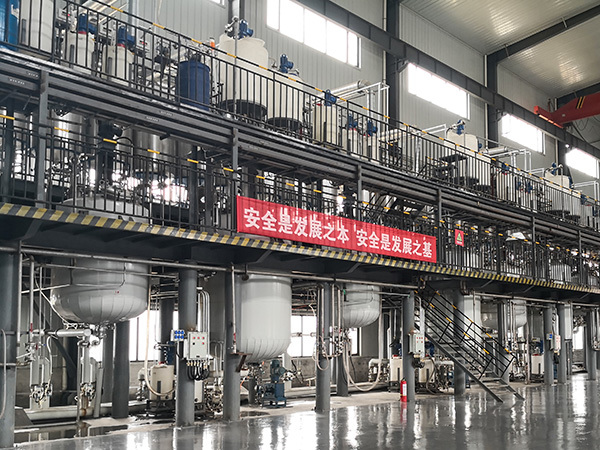

**Sulphur Granulation Machinery**

*Prilling Towers*

Prilling towers are essential equipment in the prilling technique, where molten sulphur is sprayed through nozzles at the top of the tower. The tower's design and operation play a crucial role in determining the size and quality of the granules produced.

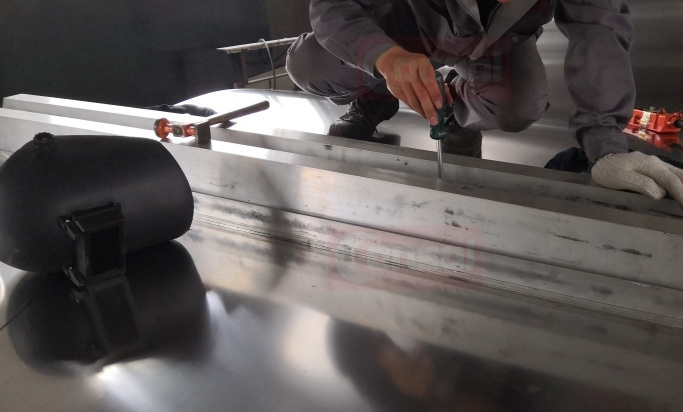

*Granulation Drums*

Granulation drums are used in the granulation technique to mix molten sulphur with binder materials. The rotating motion of the drum ensures uniform coating of the sulphur particles, resulting in well-formed granules.

*Fluid Bed Granulators*

Fluid bed granulators utilize hot air to fluidize and cool the molten sulphur, forming granules of desired size and shape. These machines offer precise control over the granulation process, making them suitable for producing granules with specific characteristics.

**Advancements in Sulphur Granulation Technology**

With ongoing research and development, the sulphur granulation industry has seen significant advancements in technology. From automated control systems to innovative granulation machinery, manufacturers are constantly striving to improve efficiency and quality in sulphur granulation processes.

**Frequently Asked Questions**

1. What is the importance of sulphur granulation in the manufacturing industry?

Sulphur granulation is crucial for converting liquid sulphur into solid granules for easy handling and transportation.

2. How do prilling towers work in the sulphur granulation process?

Prilling towers spray molten sulphur through nozzles to form spherical granules as the droplets solidify.

3. What are the advantages of fluid bed granulation in sulphur processing?

Fluid bed granulation offers better control over granule size and shape, making it ideal for producing high-quality sulphur granules.

4. How has technology advanced in sulphur granulation machinery?

Advancements in technology have led to the development of automated control systems and innovative machinery for more efficient granulation processes.

5. What are some common applications of sulphur granules in industries?

Sulphur granules are used in the production of fertilizers, pesticides, and chemicals, among other industrial applications.

**Conclusion**

In conclusion, sulphur granulation techniques and machinery play a vital role in various industries, ensuring the efficient production of high-quality sulphur granules. By understanding the different techniques and machinery available, manufacturers can optimize their processes and stay ahead in the competitive market. Stay updated on the latest advancements in sulphur granulation technology to enhance productivity and quality in manufacturing operations.

NEWS&EVENT

Steel belt pastillator granulation production line for jewelry wax middle temperature wax

Sulphur Granulation Techniques and Machinery: A Comprehensive Overview

Unleashing the Power of Sulphur Granulation in Plastic Manufacturing

Revolutionizing Plastic Production: Sulphur Granulation Explained

The Ultimate Guide to Sulphur Granulation: Everything You Need to Know

Future-Proofing Manufacturing: The Role of Conveyor Systems

Enhancing Productivity: The Benefits of Conveyor Systems

Streamlining Operations: The Power of Conveyor Systems

Revolutionizing Industrial Automation: The Power of Conveyor Systems

Copyright © 2023 Guangzhou Consol Machinery Equipment Co., Ltd. | All Rights Reserved. 粤ICP备18032917号 SEO Powered by:www.300.cn