Contact Us

E-mail info2@consolbelts.com

Phone/WhatsApp/Wechat

+86 18820135908

Perforted Steelbelt-Baking

The steam escapes evenly from the pores of the steel belt to ensure a good appearance of the product.

Стальная лента

Consol has a lot of technology to reach the requirements of different customers through mechanical or non-mechanical methods.Precise holes can be made in perforated steel belt, this kind of belt is widely used in:

Vacuum conveying

Drying

Filtering

Screening

There are no burs on both sides of the perforated steel belt, surface is smooth and bright, and the flatness will not become worse during the processing.

Application of precision microporous belt in vacuum adsorption and transfer process

In our industrial production line, there are a lot of products are suitable in the vacuum adsorption to achieve the purpose of continuous delivery products, as a kind of product with light quality and easy to slide during the process of continuous transmission, use the vacuum system at the bottom of the perforated steel belt, to transfer the production by adsorption of perforated steel belt or fixed in a setting position.

Scope of supply

Length:Customizable

Width:2000mm(No merging)

Thickness:0.4/0.5/0.8 / 1.0 / 1.2 mm

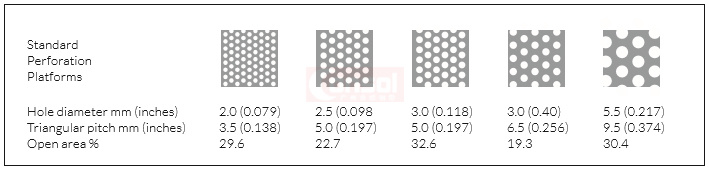

Perforated steel belts hole shapes

Enhanced Efficiency for Industrial Applications

The Consol Perforated Steel Belt is engineered to redefine efficiency in industrial conveyor belt systems. Designed specifically for industrial applications, this perforated steel belt ensures optimal steam escape, resulting in a superior product finish. Whether you're involved in vacuum conveying, drying, filtering, or screening, this belt is tailored to meet your needs. Its customizable dimensions allow it to seamlessly integrate into various metal conveyor belt setups, enhancing workflow and productivity. The precision-engineered perforations ensure consistent performance, making it an indispensable component in Precision Steel belt operations.

Built for Precision and Performance

Crafted with meticulous attention to detail, the Consol Perforated Steel Belt stands out in the realm of metal conveyor belt solutions. Its smooth and bright surface, free from burs, guarantees that the flatness remains uncompromised during processing. This belt is not only about precision but also about delivering reliable performance across diverse industrial settings. The application of precision microporous technology in vacuum adsorption and transfer processes exemplifies its capability to handle light and easy-to-slide products efficiently. As part of industrial conveyor belt systems, it ensures that products are transferred smoothly, maintaining the integrity of your production line.

Scalable Design to Meet Growing Demand

Adaptability is at the core of the Consol Perforated Steel Belt's design. With customizable lengths and widths up to 2000mm, it caters to the evolving demands of modern industries. The thickness options ranging from 0.4mm to 1.2mm provide flexibility to suit specific operational requirements. This scalability makes it a perfect fit for expanding industrial conveyor belt systems, ensuring that your setup can grow alongside your business needs. The perforated steel belt's robust construction and versatile application in vacuum conveying, drying, filtering, and screening processes make it a future-proof investment in Precision Steel belt technology, ready to meet the challenges of tomorrow's industrial landscape.

With the Consol Perforated Steel Belt, you're not just investing in a product; you're investing in a solution that enhances efficiency, precision, and scalability across your metal conveyor belt systems.

Product Advantages

1.Superior Steam Management

The Consol Perforated Steel Belt is designed to optimize steam escape, ensuring a superior product finish. This feature is crucial for maintaining quality in industrial conveyor belt systems, where consistent product appearance is vital. By allowing steam to escape efficiently, the belt enhances the overall performance of your metal conveyor belt operations, reducing defects and improving output quality.

2.Customizable Dimensions for Versatility

Tailor the Consol Perforated Steel Belt to fit your specific needs with customizable lengths and widths up to 2000mm. This adaptability ensures seamless integration into existing industrial conveyor belt systems, allowing your setup to evolve with your business. The flexibility in dimensions makes it an ideal choice for diverse applications, from vacuum conveying to drying and filtering.

3.Precision-Engineered for Consistent Performance

With precision-engineered perforations, this belt guarantees consistent performance across various metal conveyor belt applications. The smooth, burr-free surface ensures that the flatness remains uncompromised, crucial for maintaining the integrity of your production line. This precision makes it an indispensable component in Precision Steel belt operations, handling light and easy-to-slide products efficiently.

4.Scalable Design for Future Growth

The Consol Perforated Steel Belt's scalable design supports the growing demands of modern industries. With thickness options ranging from 0.4mm to 1.2mm, it provides the flexibility needed for specific operational requirements. This scalability ensures that your industrial conveyor belt systems can expand alongside your business, making it a future-proof investment in Precision Steel belt technology.

5.Enhanced Workflow and Productivity

By integrating seamlessly into various metal conveyor belt setups, the Consol Perforated Steel Belt enhances workflow and productivity. Its robust construction and versatile application in processes like vacuum conveying, drying, filtering, and screening ensure that your production line operates smoothly. This efficiency translates into cost savings and improved ROI, making it a smart choice for any industrial setting.

About CONSOL

Industry Positioning

CONSOL is a leading international enterprise specializing in steel belts and steel belt driving systems, providing reliable solutions to customers worldwide.

Core Manufacturing Capabilities and Quality Assurance

Product Range: We offer a diverse array of steel belts, including carbon steel belts, stainless steel belts, perforated steel belts, super mirror steel belts, precision steel belts, and martensitic stainless steel belts.

Application Areas: Our products are utilized across various industries such as oil & gas, chemical, food, precision machinery, film casting, woodworking, and composite industries.

Quality Commitment: We adhere to stringent quality standards to ensure our products meet the highest industry requirements.

Production Strength

Located in Guangzhou, the heart of the Pearl River Delta, CONSOL has established a robust manufacturing base, enabling us to serve clients efficiently across the globe.

Sustainability Measures

Our steel belts are designed for durability and recyclability, contributing to sustainable industrial practices.

Customer Collaboration Process

We have built a comprehensive sales and after-sales service system, coordinating installation services near our clients' facilities to ensure optimal service quality.

Global Service Capability

Over the past decade, CONSOL has exported products to more than 30 countries, including the USA, Russia, Canada, Korea, South Africa, Iran, Turkey, Ukraine, Saudi Arabia, Spain, Holland, Brazil, Malaysia, Thailand, India, Pakistan, the Philippines, Indonesia, and Vietnam.

FAQ

Who are we?

CONSOL is an international enterprise focusing on steel belts and steel belt driving systems, committed to providing reliable solutions to customers worldwide.

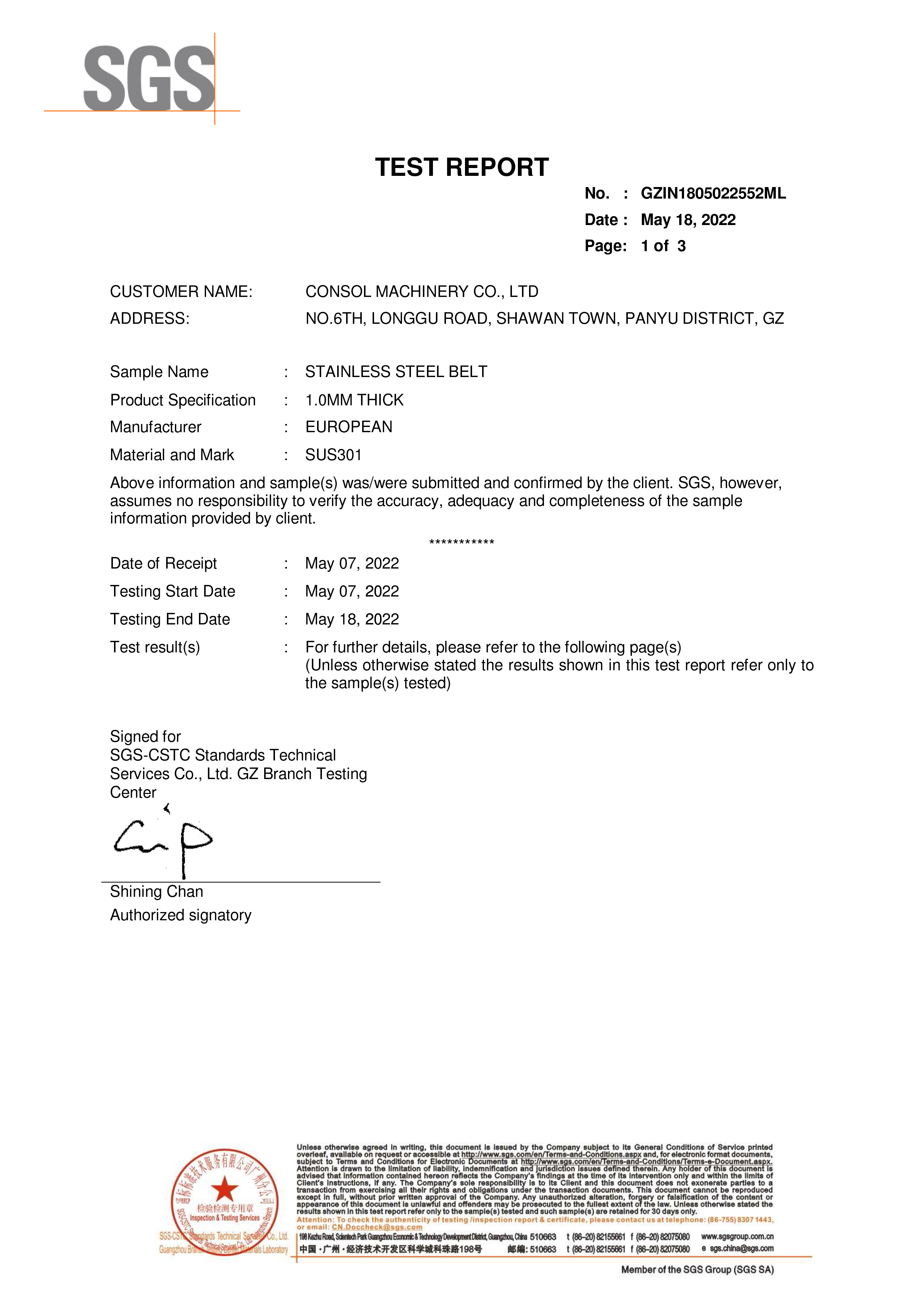

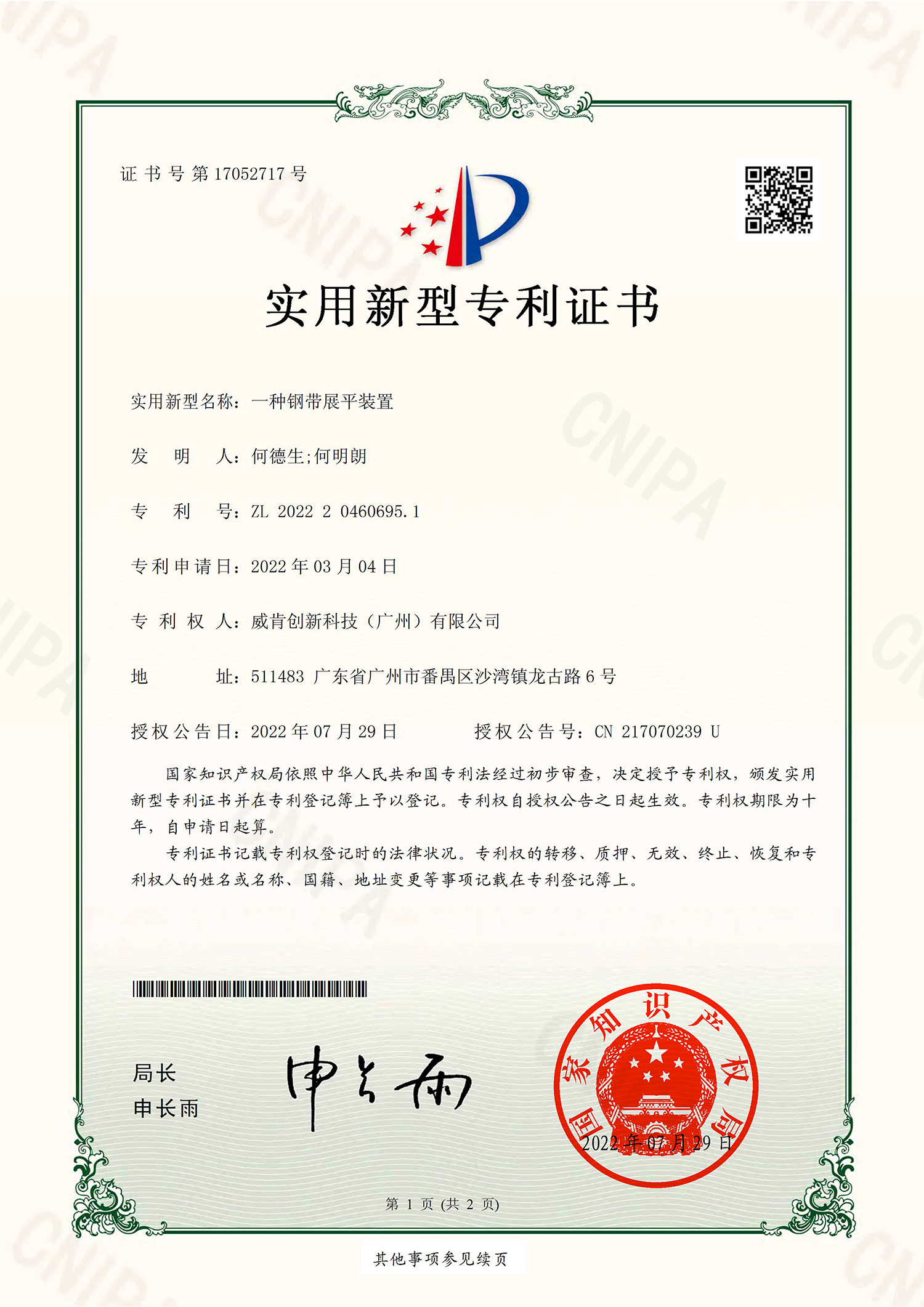

How can we guarantee quality?

We adhere to strict quality control processes and hold certifications such as SGS, CE, and ISO 9001 to ensure our products meet international standards.

What can you buy from us?

Our product offerings include various types of steel belts and conveyor systems suitable for multiple industrial applications.

Why should you buy from us and not from other suppliers?

With a decade of experience exporting to over 30 countries and a commitment to quality and customer service, CONSOL stands out as a reliable partner for your industrial needs.

What services can we provide?

We offer comprehensive services, including after-sales support, seamless welding technology, edge shaping, conveyor system rebuilding, and V-rope sticking, ensuring our clients receive end-to-end solutions.

OUR CAPABILITY

CONSOL is an international enterprise focusing on steel belt and steel belt driving system.

Keyword:

Related Products